Fermented culture medium for producing gibberellic acid

A fermentation medium and technology of gibberellic acid, applied in the direction of fermentation, etc., can solve the problems such as the adverse effects of gibberellic acid on scale and stable fermentation production, affecting the normal production and metabolism of gibberellic acid strains, and the stability of component content cannot be guaranteed. , to achieve the effect of ensuring synthesis and metabolism, ensuring activity and avoiding material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1.1 Put the GA3 strain freezing tube directly into the shake flask, the inoculation amount is 0.8% of the volume of the shake flask medium, the medium formula in the shake flask is shown in Table 1, the fermentation temperature is 29±0.2°C, and the shake flask is cultivated for about 68 hours to obtain a suspension liquid.

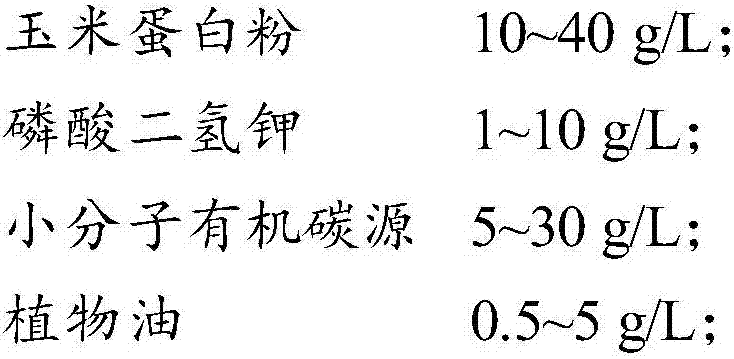

[0041] Table 1 shake flask culture medium formula

[0042]

[0043] 1.2 Inoculate the suspension into the primary seed tank with an inoculum volume of 0.016% of the volume of the culture solution. See Table 2 for the medium formula of the primary seed tank.

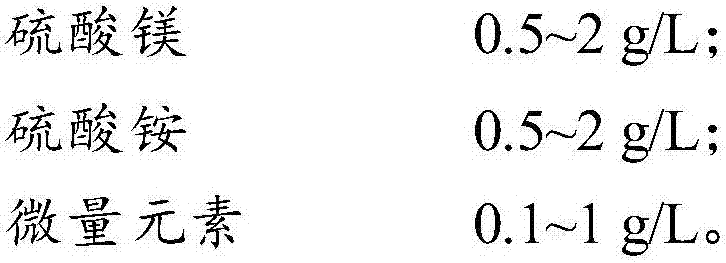

[0044] Table 2 Primary seed tank culture medium formula

[0045]

[0046] Fermentation volume: constant volume 1.3t, the volume after digestion is calculated as 1.5t (add sulfuric acid before sterilization to adjust the pH to 5.1).

[0047] Fermentation temperature: 29±0.2°C.

[0048] Operating tank pressure: 0.035MPa.

[0049] Air flow: 65Nm 3 / h.

[0050] Transplant time: CO 2 Rise...

Embodiment 2

[0078] 2.1 Transfer the seed solution obtained in 1.3 into a fermenter according to 10% to 15% of the mass of the culture solution for fermentation. The formulation of the fermentation medium is shown in Table 8.

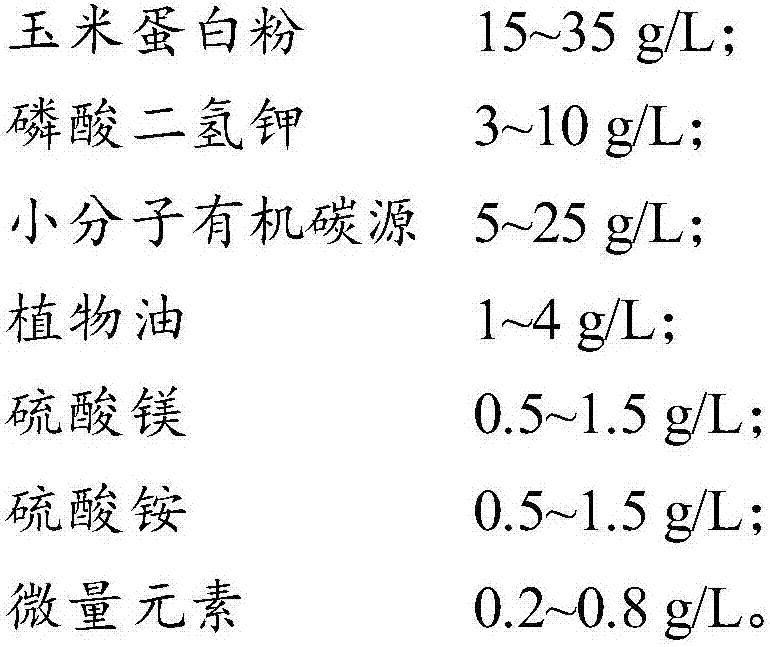

[0079] The formula of table 8 fermentation medium

[0080]

[0081] Fermentation condition is the same as example 1

[0082] The fermentation broth obtained in Example 2 was detected, and the results obtained are shown in Table 9 and Table 10.

[0083] Table 9 fermentation broth detection data

[0084]

[0085]

[0086] Table 10 Wet weight of fermentation broth

[0087]

Embodiment 3

[0089] 3.1 Transfer the seed solution obtained in 1.3 into a fermenter according to 10% to 15% of the mass of the culture solution for fermentation. See Table 11 for the formulation of the fermentation medium.

[0090] The formula of table 11 fermentation medium

[0091]

[0092] The fermentation conditions are the same as in Example 1.

[0093] The fermentation broth obtained in Example 3 was detected, and the results obtained are shown in Table 12 and Table 13.

[0094] Table 12 Fermentation broth detection data

[0095]

[0096] Table 13 Fermentation broth wet weight

[0097]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com