Device and method for testing corrosion of grounding material in soil simulated solution

A corrosion test, soil technology, applied in the direction of material inspection products, measuring devices, analyzing materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: The composition of the simulated soil solution is unchanged, and the corrosion tests are carried out on three grounding materials respectively, and the corrosion degrees are compared.

[0052] According to the physical and chemical properties of a substation soil and other characteristics, the corresponding soil simulation solution was prepared, and the composition is shown in Table 1.

[0053] Table 1 Components of soil simulation solution

[0054] NaCl

CaCl 2

MgSO 4 ·7H 2 o

NaHCO 3

Na 2 SO 4

KNO 3

pH

0.0502g / L

0.0109g / L

0.0201g / L

0.0139g / L

0.0158g / L

0.0301g / L

4.04

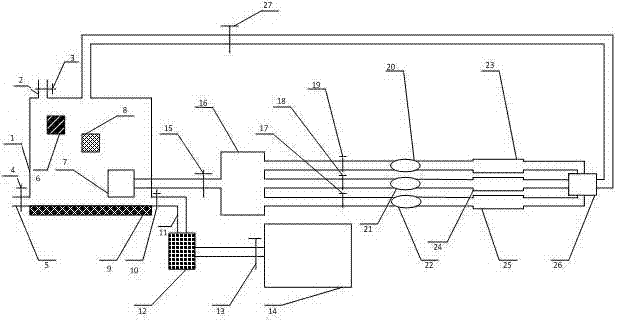

[0055] According to the structure of the test device figure 1 Build the test device platform.

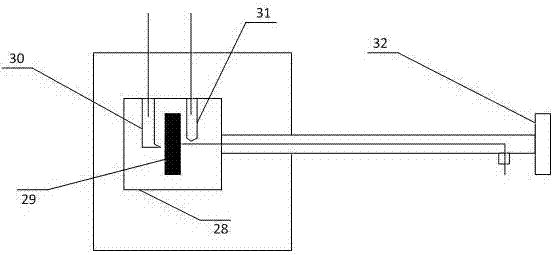

[0056] Prepare Q235 steel working electrode, galvanized steel working electrode and copper clad steel working electrode, the working area is 1cm 2 , Solder wires on the back, and seal the non-working surface with epox...

Embodiment 2

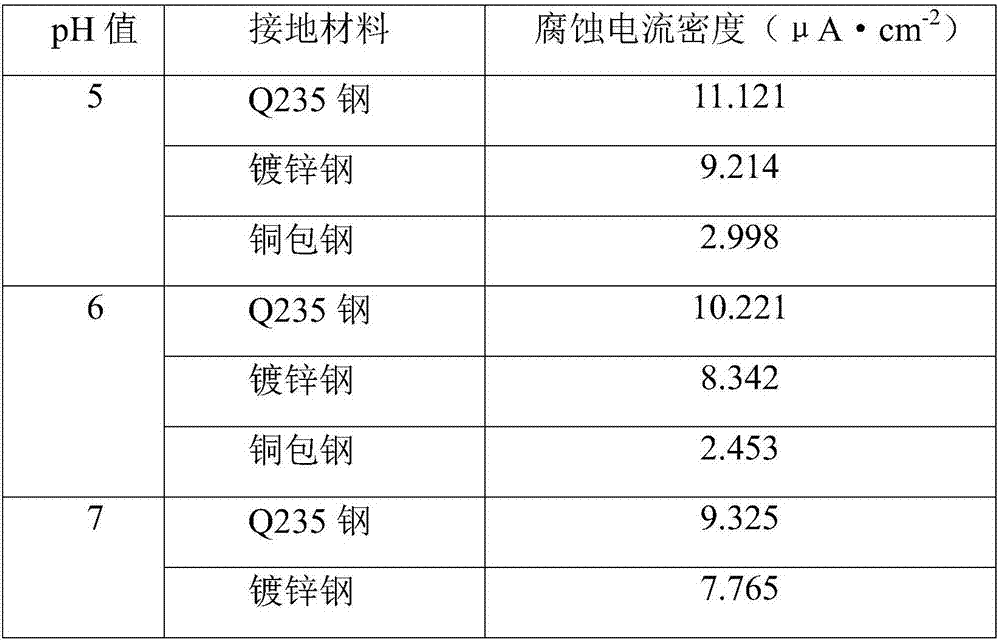

[0065] Example 2: Change the pH of the simulated soil solution, conduct corrosion tests on three grounding materials at different pH values of the simulated soil solution, and compare the corrosion degrees.

[0066] The composition of the simulated soil solution in Example 1 was changed by acetic acid or sodium hydroxide to change the pH of the simulated soil solution, and the rest remained unchanged. The pH values of the simulated soil solutions were 5, 6, 7, 8, and 9, respectively. The corrosion test was carried out respectively according to the conditions of Example 1. After the corrosion test was finished, the corrosion current density obtained by fitting the polarization curve was shown in Table 3. It can be seen from Table 3 that as the pH value increases, the corrosion current density decreases. Corrosion rate drops. Under this condition, the oxygen absorption corrosion rate of the three grounding materials is less than the hydrogen evolution corrosion rate.

[00...

Embodiment 3

[0070] Example 3: Change the content of the soil simulation solution, and conduct corrosion tests on the three grounding materials under different oxygen content of the soil simulation solution, and compare the corrosion degrees.

[0071] The oxygen content of the simulated soil solution of Example 1 was changed to 30 mg / L, 40 mg / L and 50 mg / L (±1 mg / L) respectively.

[0072] Other conditions are constant, repeat the test of embodiment 1.

[0073] After the corrosion test, the corrosion current density obtained by fitting the polarization curve is shown in Table 4. It can be seen from Table 4 that with the increase of oxygen content, the corrosion current density of the three grounding materials increases, and the corrosion rate increases. Large, indicating that under this condition, the oxygen content increases, the electrochemical reaction rate of the three materials is increased, and the corrosion rate is increased.

[0074] Table 4 Corrosion current density parameters fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com