Carbasalate calcium sustained release preparation and preparation method thereof

The technology of carbasalate calcium and sustained-release preparation is applied in the field of carbasalate calcium sustained-release preparation and preparation thereof, and can solve the problems of short biological half-life of carbasalate calcium and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A carbasalate calcium sustained-release preparation, calculated according to weight percentage, comprises the following components:

[0022] Carbasalate calcium 50%, stearic acid 7%, carnauba wax 8% and starch 35%.

[0023] Preparation:

[0024] 1) Carbasalate calcium and starch are added to the blender and mixed for 10 minutes;

[0025] 2) Stearic acid and carnauba wax are heated to 70°C and dissolved completely, then poured into a blender and mixed for 10 minutes;

[0026] 3) Put the granules in a shaker, and shake them with a 30-mesh sieve to make granules.

Embodiment 2

[0028] A carbasalate calcium sustained-release preparation, calculated according to weight percentage, comprises the following components:

[0029] Carbasalate Calcium 40%, Glyceryl Monostearate 45%, Lactose 5% and Talc 10%.

[0030] Preparation:

[0031] 1) Carbasalate calcium, lactose, and talcum powder are added to the blender and mixed for 10 minutes;

[0032] 2) After the glyceryl monostearate is heated to 70°C and completely dissolved, pour it into a blender and mix for 10 minutes;

[0033] 3) Put the granules in a shaker, and shake them with a 30-mesh sieve to make granules.

Embodiment 3

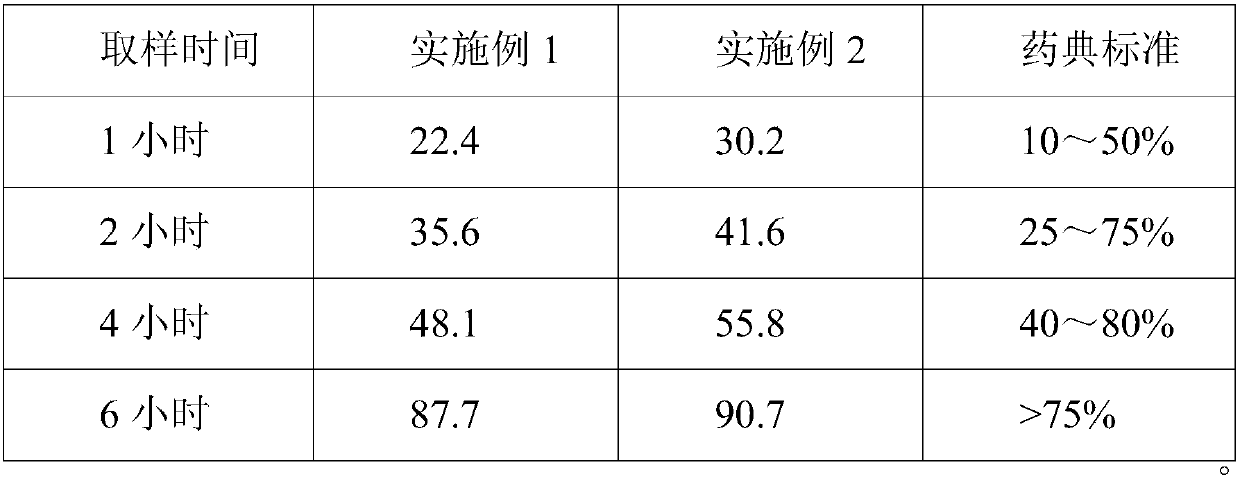

[0035] In vitro release test method:

[0036] According to the first method of dissolution, 900ml of 0.1M hydrochloric acid solution is used as the dissolution medium, and the rotating speed is 50rpm per minute. Operate according to the law. After 1, 2, 4, 6, and 8 hours, take an appropriate amount of the solution, filter it, and take the subsequent filtrate as the supply. Test solution; another carbasalate calcium reference substance was taken, accurately weighed, dissolved in a dissolution medium and quantitatively diluted to make a corresponding concentration, measured absorbance at 276nm according to ultraviolet spectrophotometry, and calculated dissolution by external standard method. Limits shall comply with the requirements in Table 1 below:

[0037] Table 1 Dissolution Requirement Limit Table

[0038] time

scope

1 hour

10~50%

2 hours

25~75%

4 hours

40~80%

6 hours

>75%

[0039] Carbasalate calcium slow-release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com