High-temperature hydrolysis type oil-containing sediment harmless comprehensive treatment process

A comprehensive treatment, high-temperature hydrolysis technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of incomplete treatment of oily sludge and low operating costs, Achieve the effects of wide range of sludge treatment, harmless treatment, and advanced process schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

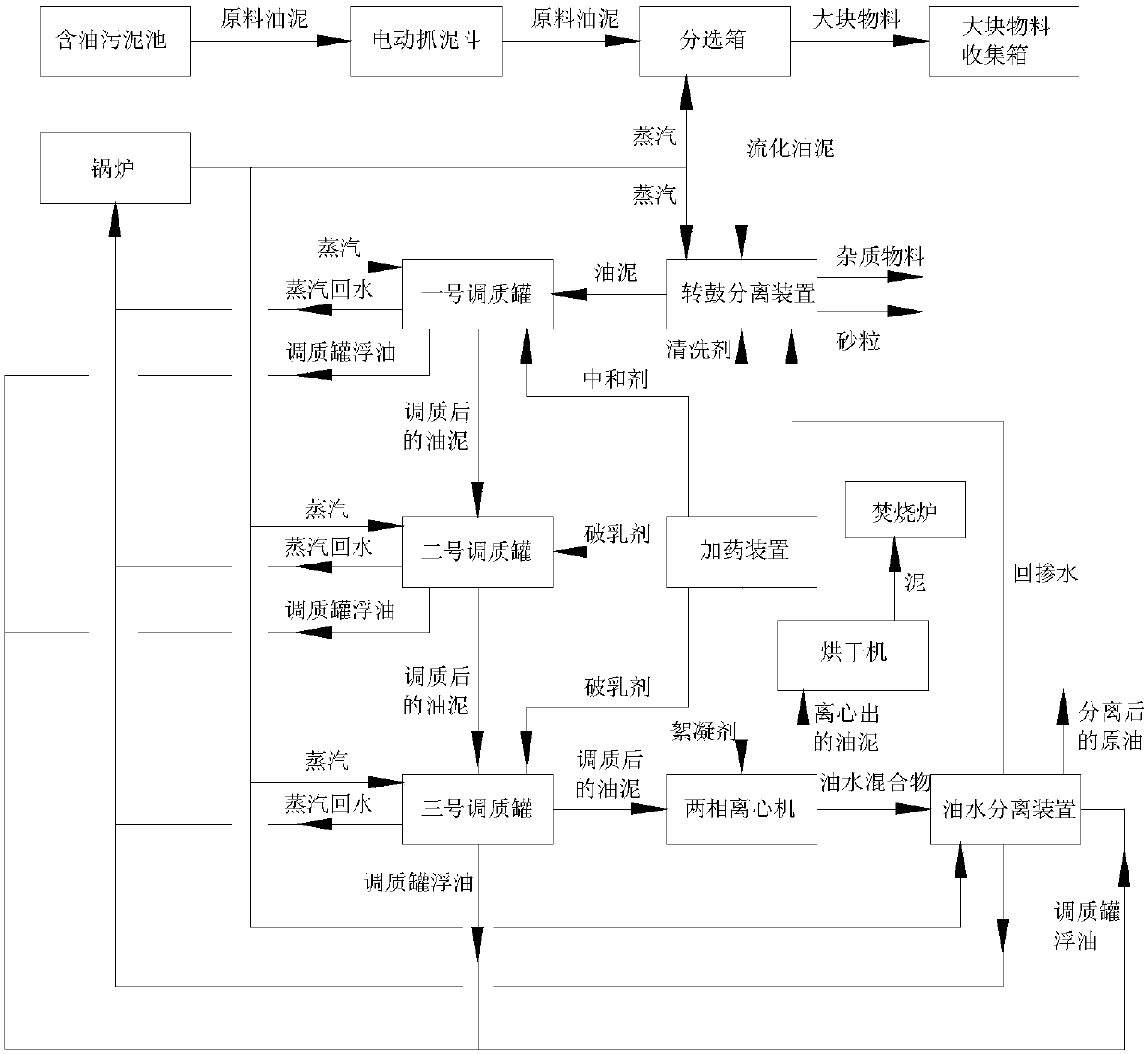

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] A high-temperature hydrolysis type oily sediment harmless comprehensive treatment process, including the following steps, the flow chart is shown in figure 1 :

[0018] (1) Sludge fluidization and pretreatment: Sorting oily sludge to remove large solid impurities from the sludge. First, the electric mud grab is manually controlled to grab the solid sludge into the sorting box, and steam is introduced into the sorting box, and the steam volume can be controlled by an electric valve. There are three layers of steam nozzles with nozzles in the sorting box, which can ensure that the sludge is in a good fluidization state, and the solid materials with a diameter greater than 50mm are sorted out through the vibrating screen and discharged to the bulk material collection box, with a diameter of less than 50mm. The mixture is sent to the drum separator. The material enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com