Shotcrete and preparation method thereof

A shotcrete and mixture technology, applied in the field of high-performance concrete, can solve the problems of raw material waste and large rebound rate of shotcrete, and achieve the effects of reducing waste, reducing rebound and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

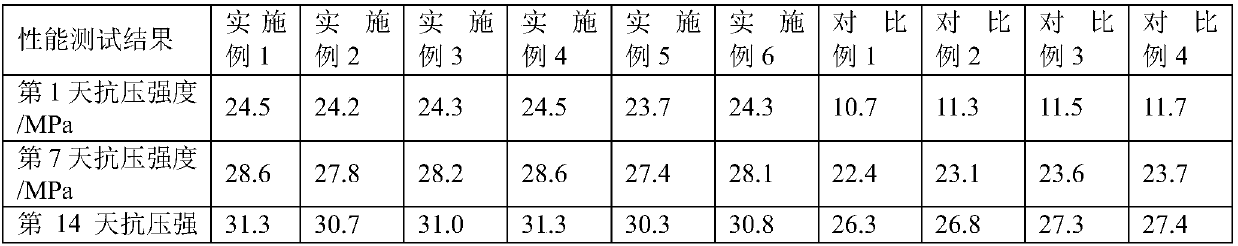

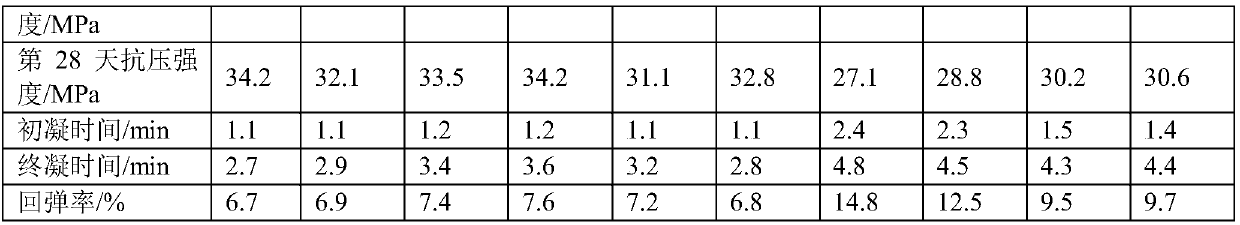

Examples

Embodiment 1

[0026] S1: Take 970kg of sand and 647kg of crushed stone and stir, and the mixing time is 16s to obtain a mixture, wherein the particle size of crushed stone is 10mm;

[0027] S2: Take 404 kg of Portland cement and add it to the mixture obtained in S1, and the mixing time is 18s to obtain the mixture;

[0028] S3: Take 0.8 kg of 2,6-dimethyl-7-octene-2-ol, 0.8 kg of cis-3-hexenol formate, and 202 kg of water into the ultrasonic mixer. The reaction temperature is 100°C. The stirring time is 37 minutes, then 6.46 kg of quaternary ammonium salt polycarboxylic acid water reducing agent, 8.08 kg of polyaluminum sulfate, and 8.08 kg of sodium carbonate are added, and the mixture is stirred for 2 minutes to obtain a mixture;

[0029] S4: Load the mixture obtained from S3 into the sprayer, and use high-pressure air to transport it to the nozzle. At the same time, the mixture obtained by S2 is passed through the nozzle of the sprayer. After mixing the mixture obtained by S2 and the mixture ob...

Embodiment 2

[0031] S1: Take 950kg of sand and 610kg of crushed stone and stir, and the stirring time is 15s to obtain the mixture, wherein the particle size of the crushed stone is 12mm;

[0032] S2: Take 428kg of Portland cement and add it to the mixture obtained in S1, and the mixing time is 17s to obtain the mixture;

[0033] S3: Take 0.8 kg of 2,6-dimethyl-7-octene-2-ol, 1 kg of cis-3-hexenol formate, and 190 kg of water into the ultrasonic stirrer. The reaction temperature is 90°C and stir The time is 36 minutes, after which 5.86 kg of quaternary ammonium salt polycarboxylic acid water reducing agent, 8.16 kg of polyaluminum sulfate, and 8.16 kg of sodium carbonate are added, and stirred for 1 minute to obtain a mixture;

[0034] S4: Load the mixture obtained from S3 into the sprayer, and use high-pressure air to transport it to the nozzle. At the same time, the mixture obtained by S2 is passed through the nozzle of the sprayer. After mixing the mixture obtained by S2 and the mixture obtain...

Embodiment 3

[0036] S1: Take 990kg of sand and 610kg of crushed stone and stir, and the stirring time is 15s to obtain the mixture, wherein the particle size of crushed stone is 12mm;

[0037] S2: Take 380kg of Portland cement and add it to the mixture obtained in S1, and the mixing time is 19s to obtain the mixture;

[0038] S3: Take 0.9 kg of 2,6-dimethyl-7-octene-2-ol, 1 kg of cis-3-hexenol formate, and 190 kg of water into the ultrasonic stirrer. The reaction temperature is 110°C and stir The time is 36 minutes, after which 5.86 kg of quaternary ammonium salt polycarboxylate water reducing agent, 8.16 kg of polyaluminum sulfate, and 8 kg of sodium carbonate are added, and stirred for 3 minutes to obtain a mixture;

[0039] S4: Load the mixture obtained from S3 into the sprayer, and use high-pressure air to transport it to the nozzle. At the same time, the mixture obtained by S2 is passed through the nozzle of the sprayer. After mixing the mixture obtained by S2 and the mixture obtained by S3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com