Method for removing acetic acid and method for producing cyclohexyl acetate and cyclohexanol

A technology of cyclohexyl acetate and cyclohexanol, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, purification/separation of hydrocarbons, etc., can solve problems such as adverse effects of reactions and equipment corrosion, and achieve good ability to capture acetic acid , avoid corrosion, easy to prepare the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

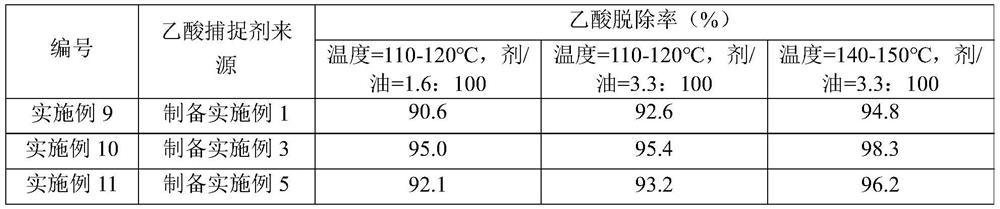

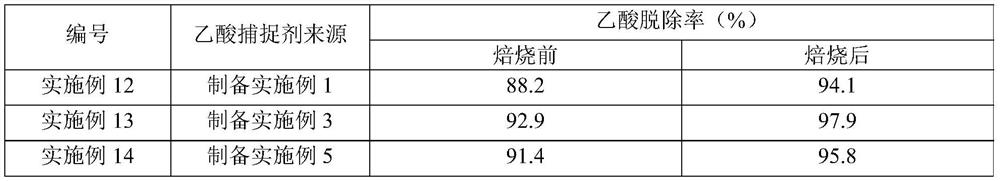

Examples

preparation Embodiment 1

[0132]50kg CA (OH)210kg (with molecular sieve dry base) 5A molecular sieve (purchased from Henan Mingze Environmental Protection Technology Co., Ltd.), 30kg MGCO3And 5kg aluminum sol (purchased from Shandong Chilean Chemical Co., Ltd.), the alumina content is 12% by weight) placed in a disc type granulator (purchased from Shanghai Kezi Chi Chemical Equipment Technology Co., Ltd.), gradually spraying deion Water, making materials into the ball. The resulting sphere (diameter was 3-6 mm) was dried at 120 ° C for 4 h at 600 ° C to obtain a acetic acid capture agent, which consisted in Table 1.

preparation Embodiment 2

[0138]The acetic acid capture agent was prepared using the same method as in the preparation Example 1, and the difference is Ca (OH)2The amount of usage is 77kg.

preparation Embodiment 3

[0148]60kg CaO, 8kg (by molecular sieve dry base) 13X molecular sieve (purchased from Langfang Pengcai Fine Chemical Co., Ltd.), 10kg MG (OH)2And 5kg silica sol (purchased from Zhejiang Yuda Chemical Co., Ltd., a silica content of 25% by weight) placed in a disc type granulator (purchased from Shanghai Kezhen Chemical Equipment Technology Co., Ltd.), gradually spraying deion Water, making materials into the ball. The resulting sphere (a diameter of 3-6 mm) was dried at 140 ° C for 6 h at 520 ° C for 6 h, thereby obtaining a acetic acid capture agent, the composition of the acetic acid capture agent in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com