Method for separating low-concentration 1,2-butanediol from ethylene glycol by adopting azeotropic distillation

A technology of azeotropic distillation and azeotropic distillation column, which is applied in the field of refining high-purity ethylene glycol, can solve the problems of increasing the complexity of the process and operating energy consumption, so as to reduce equipment investment and energy consumption, and achieve important economic value , The effect of simplifying the separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

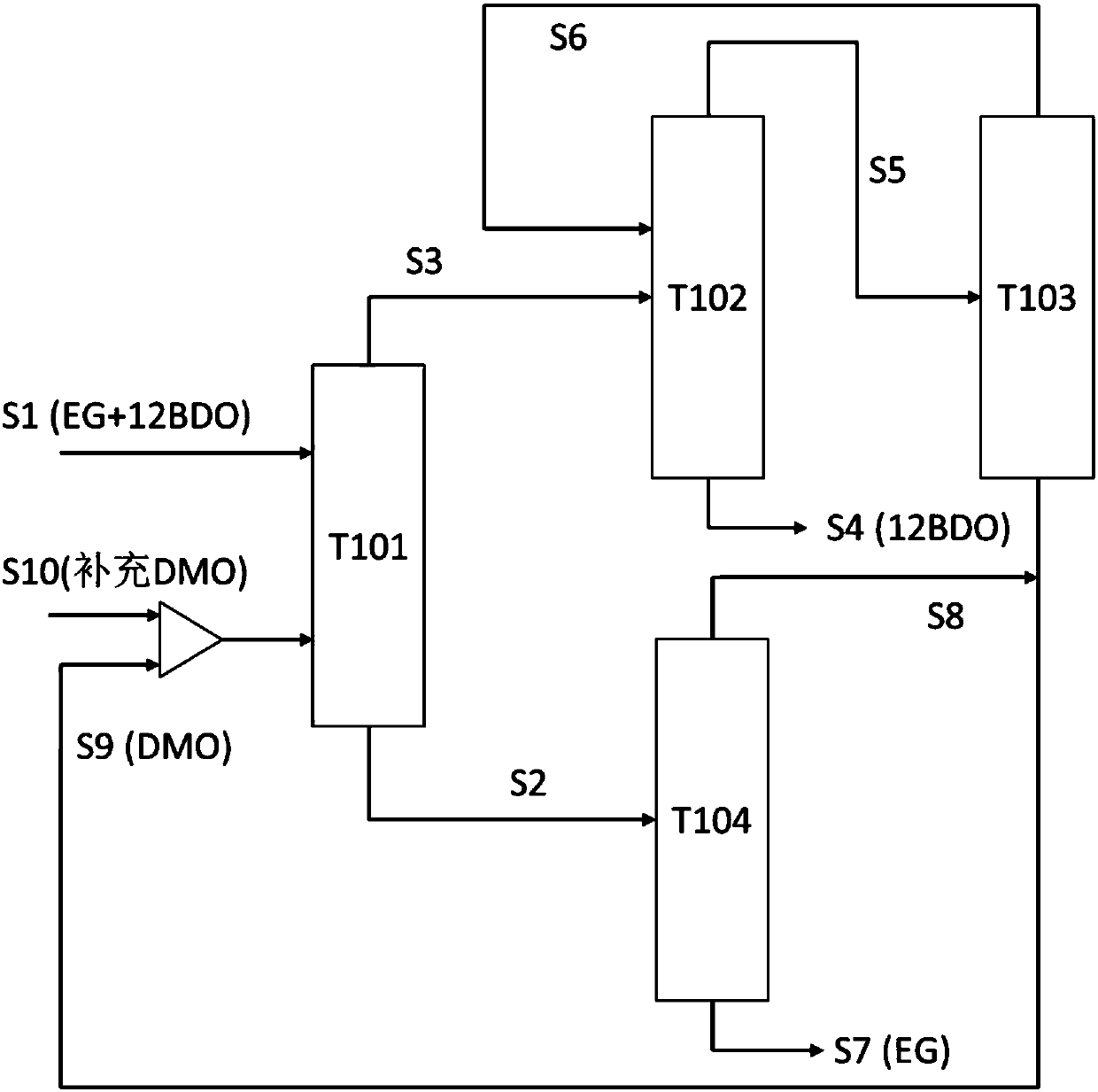

[0029] The flow rate is 1000kmol / hr, the raw material containing 99.8% ethylene glycol (EG) and 0.2% (mol) 1,2-butanediol (12BDO) enters the EG-12BDO separation tower T101 together with dimethyl oxalate (DMO) , the operating pressure of the separation tower T101 is 10bar, the number of plates is 60, and the reflux ratio is 10; the bottom of the tower is the azeotropic mixture of EG and the entrainer DMO, and the mixture at the bottom of the tower then enters the EG refining tower T104; the top of the tower is the mixture of DMO and 12BDO , then enter the low-pressure azeotropic distillation column T102;

[0030] The operating pressure of EG refining tower is 10bar, plate number 72, reflux ratio 12; Obtain the EG product of 994.3kmol / h, 99.9% (mol) at the bottom of the tower of refining tower; Tower top is DMO, returns to as entrainer circulation Separation tower T101;

[0031] The operating pressure of the low-pressure azeotropic rectification tower T102 is 5 bar, the plate n...

Embodiment 2

[0034] The flow rate is 1000kmol / hr, the raw material containing EG99.8% and 12BDO0.2% (mol) enters the EG-12BDO separation tower T101 together with DMO, the operating pressure of the separation tower T101 is 10bar, the number of plates is 60, and the reflux ratio is 10 The tower bottom is the mixture of EG and entrainer DMO, and the mixture at the bottom of the tower enters the EG refining tower T104 subsequently; The tower top is the azeotropic mixture of DMO and 12BDO, enters the low-pressure azeotropic rectification tower T102 subsequently;

[0035] The operating pressure of the EG refining tower T104 is 10 bar, the number of plates is 72, and the reflux ratio is 12; the EG product of 995.6 kmol / h and 99.9% (mol) is obtained at the bottom of the tower, and the top of the tower is DMO, which is recycled back to the separation tower as an entrainer T101;

[0036] The operating pressure of the low-pressure azeotropic distillation column T102 is 5 bar, the number of plates is ...

Embodiment 3

[0039] Flow rate is 1000kmol / hr, contains EG 95%, and the raw material containing 12BDO 5% (mol) enters EG-12BDO separating tower T101 together with DMO, and the operating pressure of separating tower T101 is 9bar, plate number 70, flow ratio 8; The bottom is a mixture of EG and the entrainer DMO, and the bottom mixture then enters the EG refining tower T104; the top of the separation tower T101 is the azeotropic mixture of DMO and 12BDO, and the top mixture then enters the low-pressure azeotropic distillation tower T102;

[0040] The operating pressure of the EG refining tower T104 is 9 bar, the number of trays is 84, and the reflux ratio is 8; the EG product of 947.9 kmol / h and 99.9% (mol) is obtained at the bottom of the tower, and the top of the tower is DMO, which is recycled to the T101 tower as an entrainer;

[0041] The operating pressure of the low-pressure azeotropic distillation column T102 is 8 bar, the number of trays is 75, and the reflux ratio is 11; 49.635 kmol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com