Parallel liquid polypropylene production method and application thereof

A production method and liquid-phase propylene technology, applied in the field of olefin polymerization, can solve the problems of increasing the difficulty of equipment reconstruction and construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

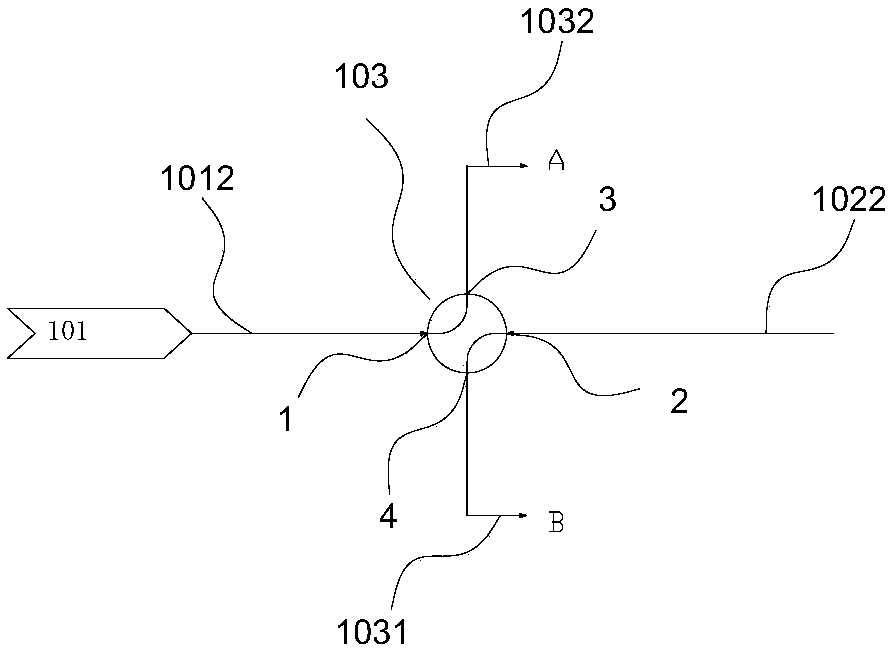

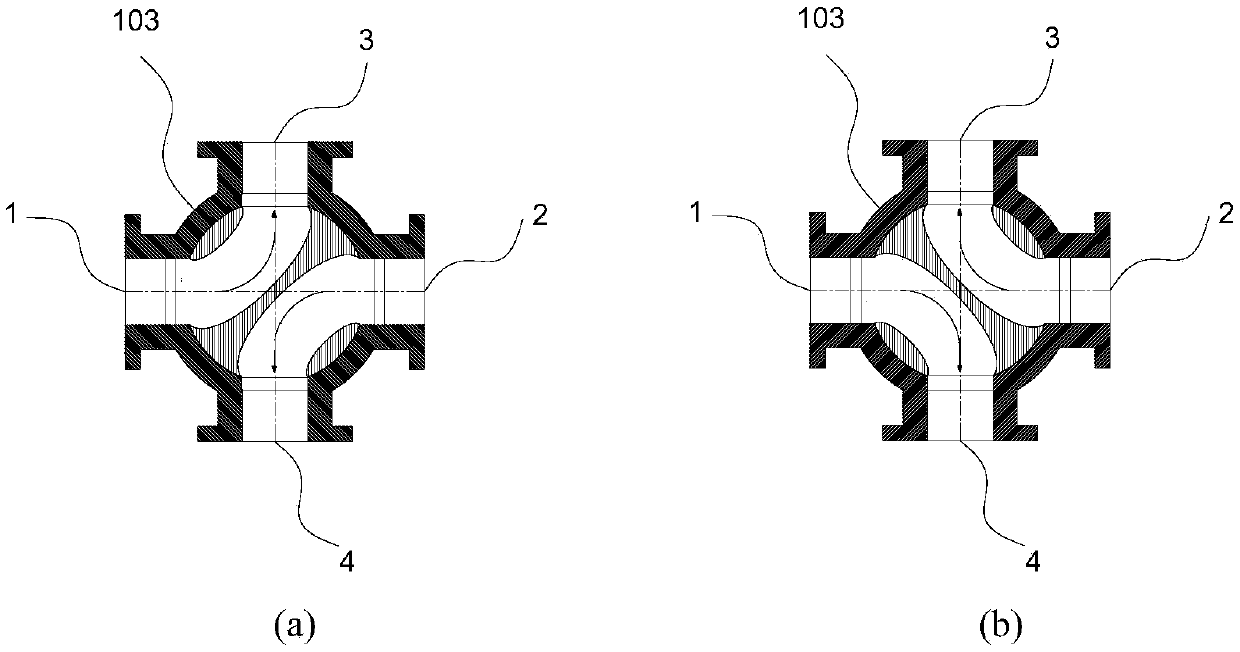

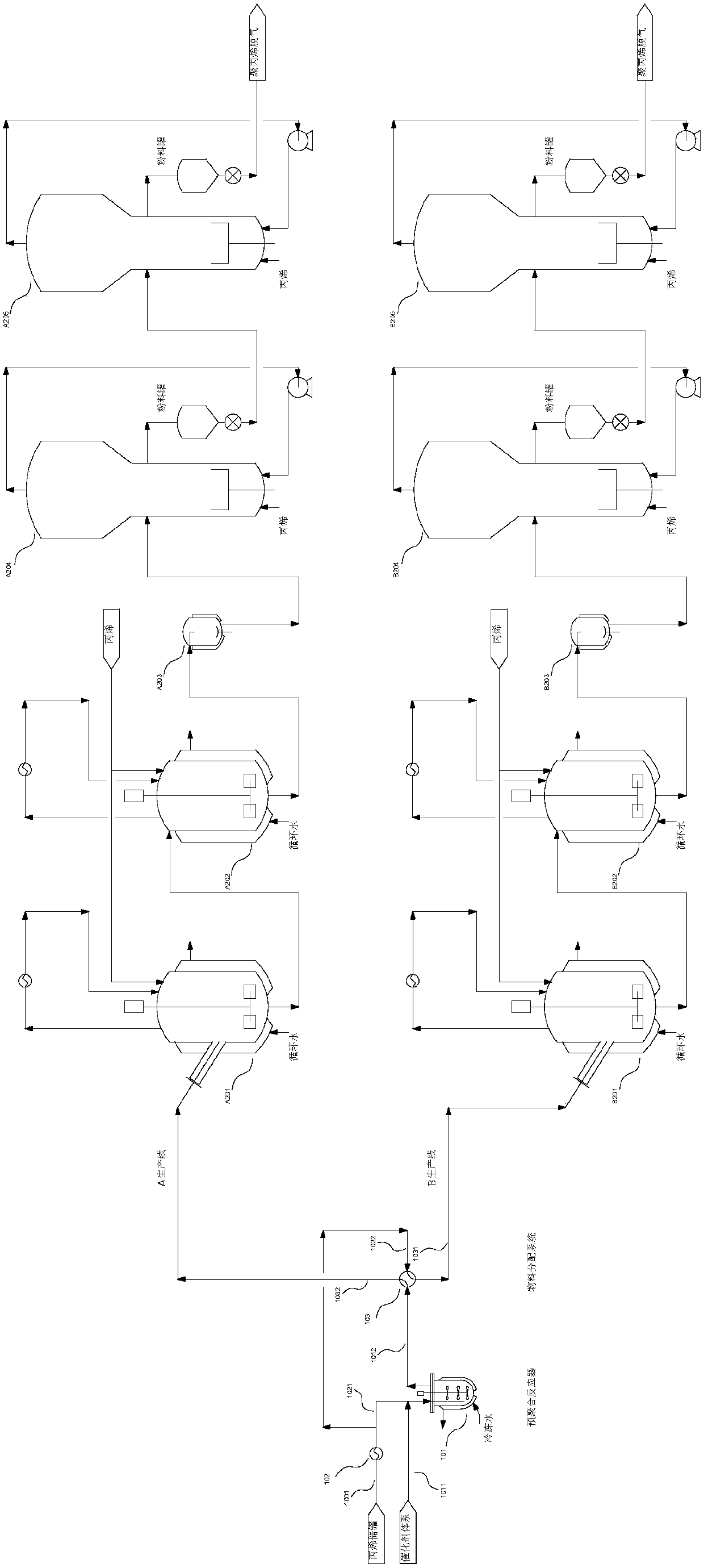

[0086] Embodiment 1: the polypropylene production method that two Hypol process production lines are connected in parallel

[0087] This embodiment adopts two parallel Hypol process production lines to produce polypropylene, and its flow chart is as follows image 3 shown. The prepolymerization of propylene adopts the continuous liquid phase bulk prepolymerization method. The pre-polymerization reactor 101 is a vertical stirred tank reactor, and a multi-layer inclined paddle stirrer is used to mix the materials in the tank evenly and enhance heat transfer. The heat of polymerization was withdrawn by the cryogenic liquid propylene feed and chilled water in the jacket of the prepolymerization reactor. Among them, the low-temperature liquid propylene is the propylene in the propylene delivery pipeline 1001 that is cooled to 5°C by the heat exchanger 102, and then divided into two streams. The propylene through the pipeline 1021 goes to the prepolymerization reactor 101, and the...

Embodiment 2

[0090] Embodiment 2: the polypropylene production method that two Spheripol process production lines are connected in parallel

[0091] This embodiment adopts two parallel Spheripol processes to carry out polypropylene production, and its flow chart is as follows Figure 4 shown. The prepolymerization method of propylene is continuous liquid phase bulk prepolymerization. The pre-polymerization reactor 101 is a loop reactor, and the materials in the reactor are moved at a high speed through an axial flow pump to enhance heat transfer. The heat of polymerization is withdrawn by the cryogenic liquid propylene feed and chilled water in the jacket of the prepolymerization reactor 101 . The propylene feed enters the propylene cooler 102 through the pipeline 1001, and enters the main reactor of the production line through the pipeline 1002 for polymerization. Among them, the low-temperature liquid propylene is the raw material propylene in the propylene transportation pipeline 100...

Embodiment 3

[0096] Embodiment 3: the polypropylene production method that two Spheripol process production lines are connected in parallel

[0097] This embodiment adopts two parallel Spheripol processes to carry out polypropylene production, and its flow chart is as follows Figure 5 As shown, the two production lines each have independent prepolymerization reactors, respectively A101 and B101, and are in mutual standby state. Prepolymerization conditions were the same as in Example 2.

[0098] The two polypropylene production lines each have an independent prepolymerized material distribution system, which is the same as that in Embodiment 1. The multi-channel switching valve groups in the pre-polymerized material distribution system on the two production lines are four-way ball valves A103 and B103 respectively, and the multi-channel switching valve groups on the two production lines are all in the stop switching state and do not perform periodic switching. Both polypropylene product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com