Starch adhesive for rosin tackifying

A technology of starch adhesive and rosin, which is applied in the direction of starch adhesive, adhesive type, polymer adhesive additive, etc., can solve the problems of cost increase, corrugated paper easy to absorb moisture, strength decline, etc., and achieve good weather resistance and Persistence, easy synthesis method, effect of reducing hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

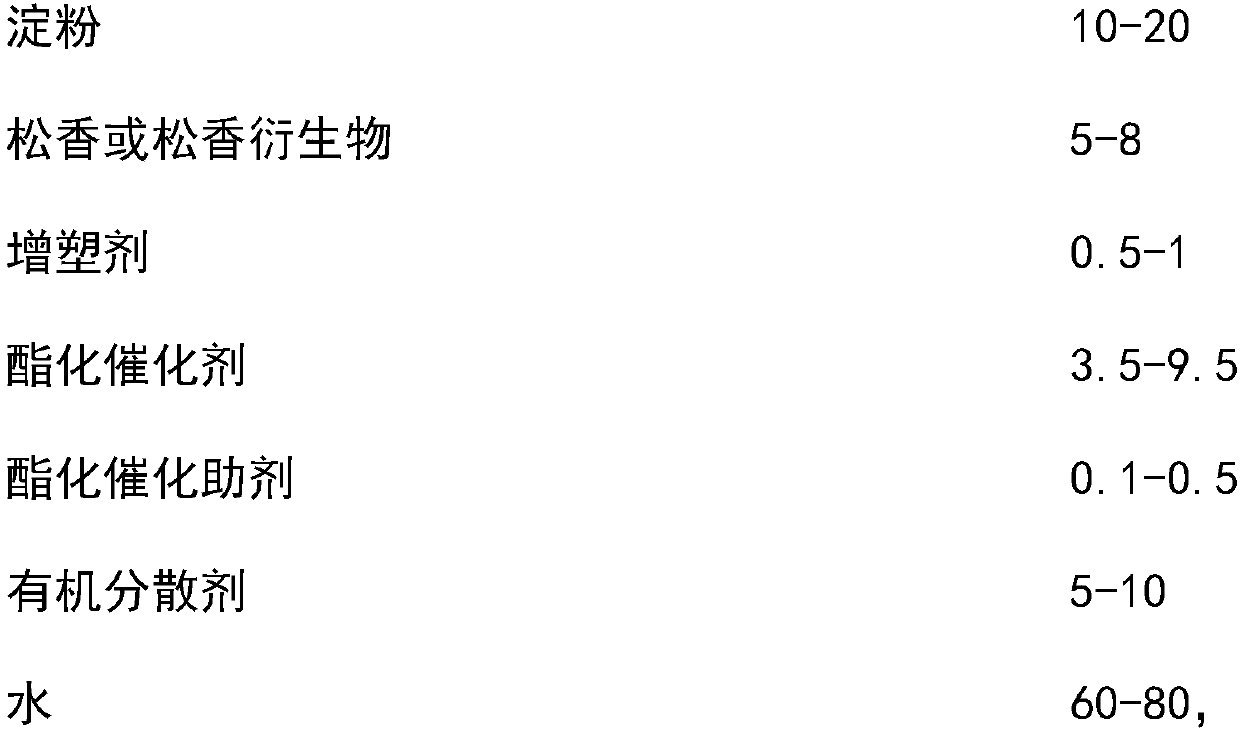

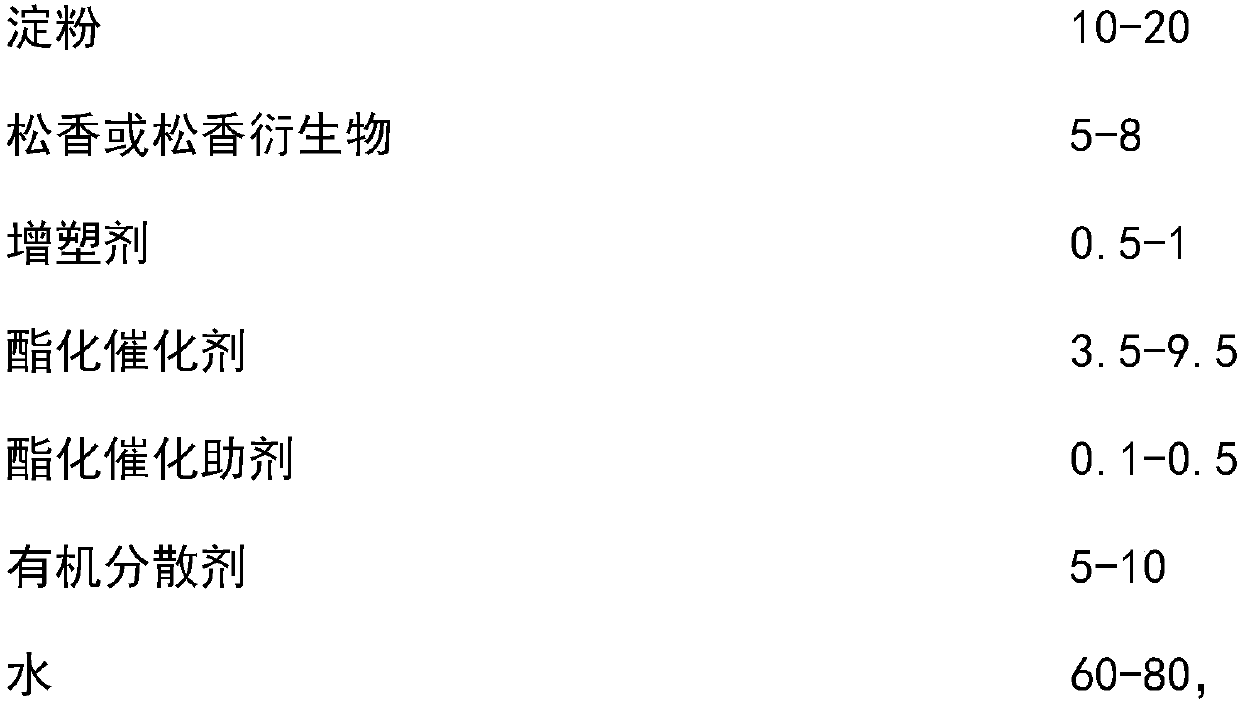

Method used

Image

Examples

Embodiment 1

[0031] In a 2L reaction kettle with an ultrasonic stirring probe and a heat exchange tube, put 20g of cornstarch, 6g of hydrogenated rosin and 10g of methylene chloride, turn on the ultrasound, and perform ultrasonic treatment for 20min at a power of 400W to fully disperse the material. Then feed water at 0°C into the heat exchange tube, lower the temperature of the reaction material to 2°C, and then put 4.5g of DCC and 0.2g of DMPA into the reactor, and ultrasonically react at this temperature for 1.5h; then stop the supply of cooling water , continue the ultrasonic reaction, gradually warm the system to room temperature, and maintain this temperature, continue to react for 15h. Then, 1 g of glycerin and 70 g of water were put into the reactor for 5 times, and ultrasonically dispersed for 20 min to obtain a starch adhesive thickened by rosin.

Embodiment 2

[0033] Put 150g of sweet potato starch, 8g of rosin and 8g of dichloromethane into a 2L reactor with an ultrasonic stirring probe and a heat exchange tube, turn on the ultrasound, and perform ultrasonic treatment for 28min at a power of 400W to fully disperse the material. Then feed water at 0°C to the heat exchange tube, reduce the temperature of the reaction material to 2°C, then put 6g DIC and 0.25g DMPA into the reactor, and perform ultrasonic reaction at this temperature for 2 hours; then stop the supply of cooling water and continue Ultrasonic reaction, the system was gradually warmed to room temperature, and maintained at this temperature, continued to react for 16h. Then, 0.8 g of ethylene glycol and 80 g of water were put into the reactor for 5 times, and ultrasonically dispersed for 20 min to obtain a starch adhesive thickened by rosin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com