A kind of preparation method of modified negative oxygen ion powder

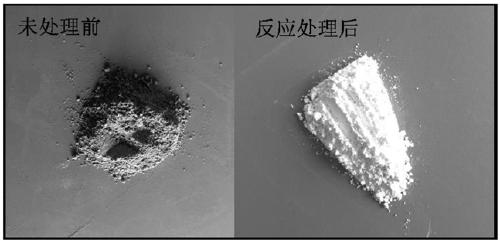

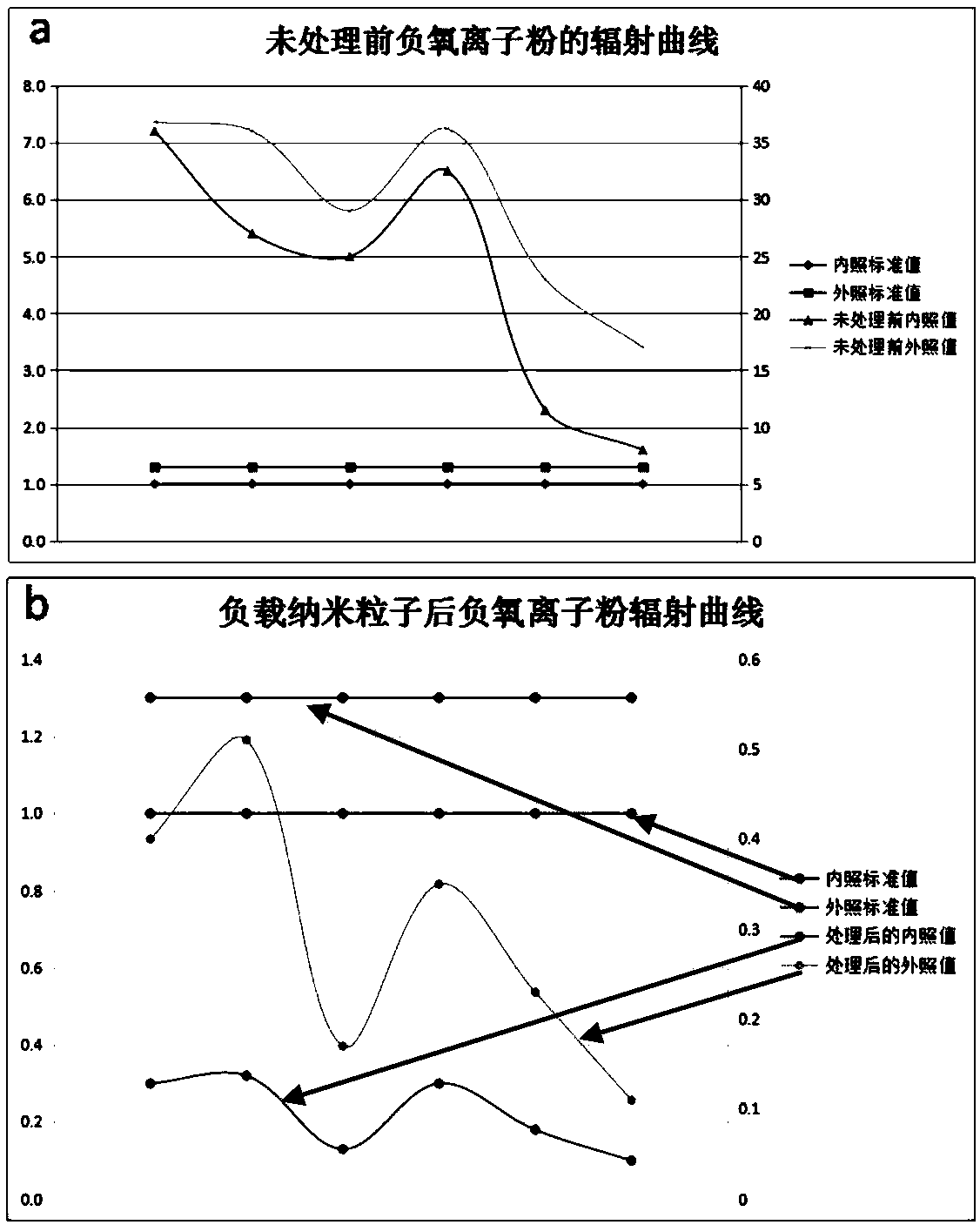

A negative oxygen ion powder and modification technology, which is applied in chemical instruments and methods, electrotherapy, treatment, etc., can solve the problems of high lateral irradiation and poor apparent properties of negative oxygen ion powder, and achieve the dispersion of apparent properties Enhanced performance, enhanced use value, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

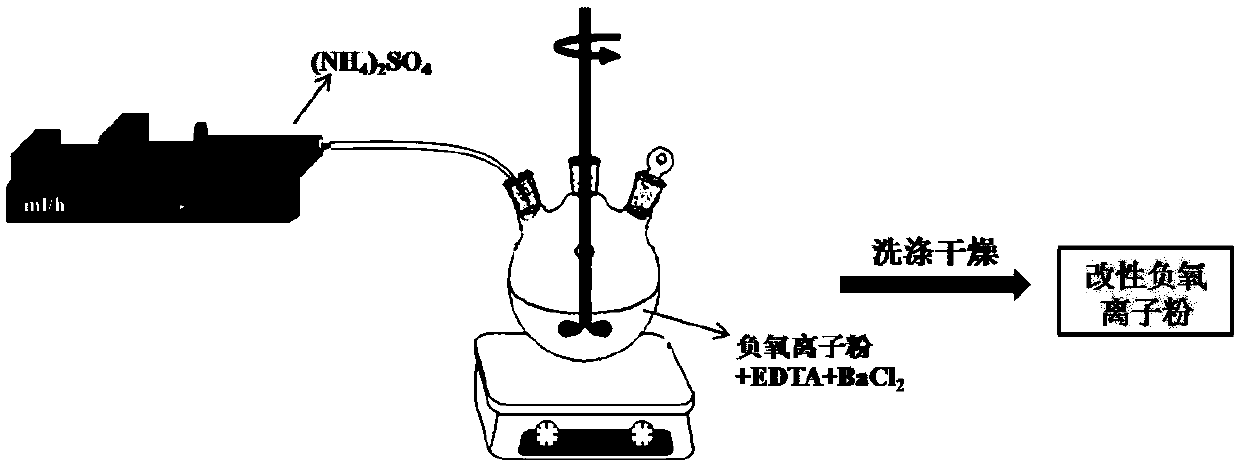

[0025] Specific embodiment one: the preparation method of this embodiment modified negative oxygen ion powder is implemented according to the following steps:

[0026] 1. Prepare 50-60 mL each of 0.5 mol / L ammonium sulfate solution, barium chloride solution and EDTA solution;

[0027] 2. Under the condition of stirring at room temperature, pour 50-60mL EDTA solution into 50-60mL barium chloride solution, adjust the pH of the system with ammonia water to 6-8, and stir for 20-30min;

[0028] 3. Take another 500mL three-necked bottle, add 5.8-11.6g of negative oxygen ion powder, add the above mixed solution under stirring conditions, and stir for 5-8 minutes to make it evenly mixed;

[0029] 4. Add 50-60mL ammonium sulfate solution dropwise, speed up the stirring, and stir for 30-40min;

[0030] 5. After standing still, wash with deionized water and ethanol for 3 to 5 times, and then dry in an oven at 55 to 65°C to obtain negative oxygen ion powder loaded with nano barium sulfat...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that the temperature in step 2 is 45°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the pH of the system in Step 2 is 8-10, and other steps and parameters are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com