Dirt cleaning agent for reverse osmosis membrane

A technology of reverse osmosis membrane and cleaning agent, which is applied in the field of fouling cleaning agent for reverse osmosis membrane, which can solve the problems of reduced water production, decreased system desalination rate, fouling of reverse osmosis membrane, etc., to prolong membrane life and maintain membrane flux , Improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

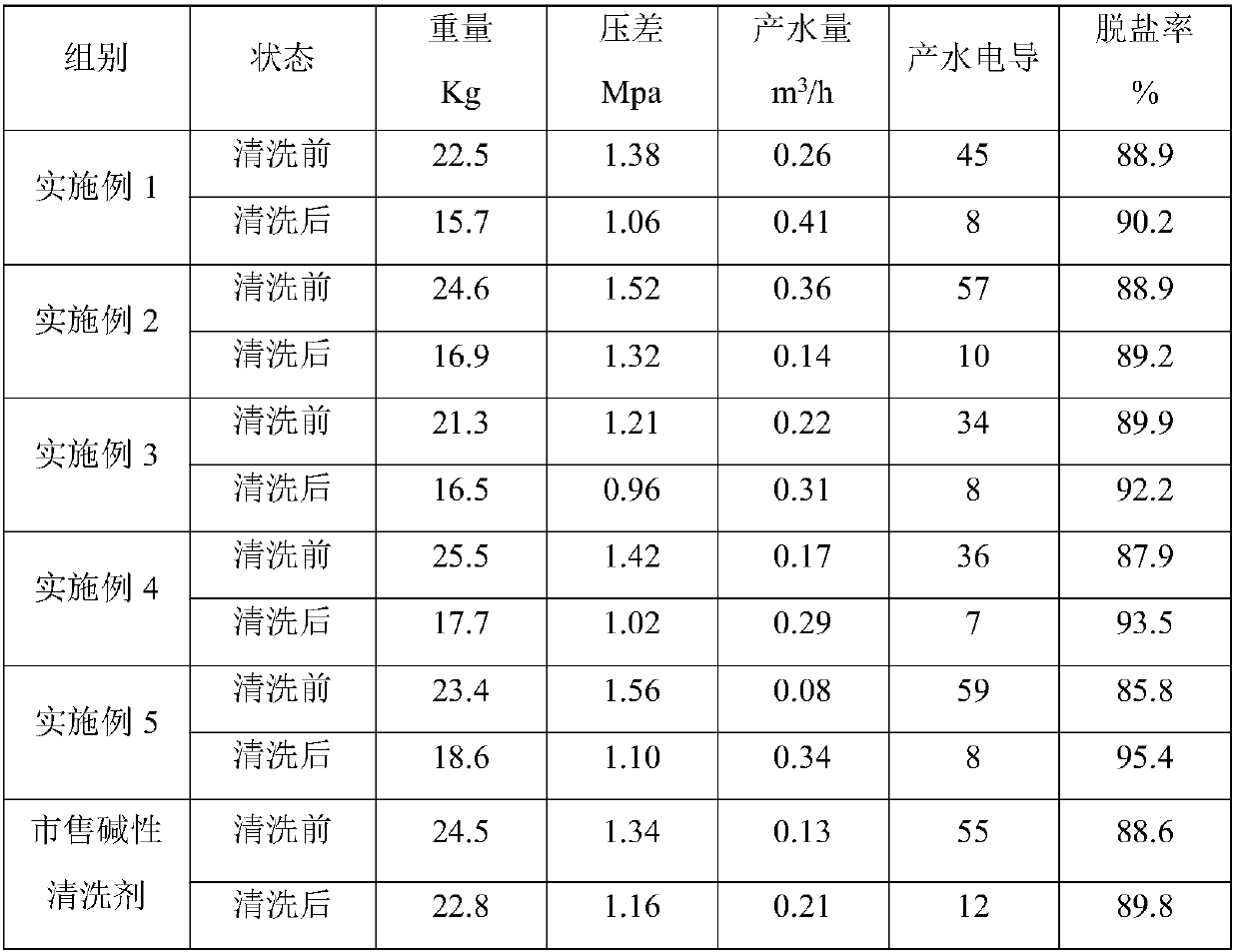

Examples

Embodiment 1

[0027] A dirt cleaning agent for a reverse osmosis membrane, comprising the following components by weight percentage: 15% sodium fatty alcohol polyoxyethylene ether sulfate, 28% sodium dodecylbenzenesulfonate, 0.8% metal complexing agent, Anti-sedimentation agent 3.8%, lauryl diethanolamine 17.6%, sodium xylene sulfonate 8%, sodium chloride 3.5%, sodium sulfate 0.4%, bactericide 0.8% and the balance of deionized water.

[0028] The metal complexing agent is triethanolamine; the anti-deposition agent is coconut oil monoethanolamine; the fungicide is DBNPA.

[0029] A preparation method of dirt cleaning agent for reverse osmosis membrane, the method steps are as follows:

[0030] S1: Stir the anionic surfactant, metal complexing agent, anti-sedimentation agent, lauroyl diethanolamine, sodium xylene sulfonate and deionized water at 45°C for 20min at a stirring speed of 500rpm;

[0031] S2: When the temperature of S1 drops to 30°C, add the fungicide, stir for 10 minutes, and the...

Embodiment 2

[0034] A dirt cleaning agent for a reverse osmosis membrane, comprising the following components by weight percentage: 17% sodium fatty alcohol polyoxyethylene ether sulfate, 28.5% sodium dodecylbenzenesulfonate, 0.8% metal complexing agent, 4.0% of anti-deposition agent, 19% of lauroyl diethanolamine, 8.2% of sodium xylene sulfonate, 3.8% of sodium chloride, 0.5% of sodium sulfate, 0.85% of bactericide and the balance of deionized water.

[0035] The metal complexing agent is triethanolamine; the anti-deposition agent is coconut oil monoethanolamine; and the bactericide is isothiazolinone.

[0036] A preparation method of dirt cleaning agent for reverse osmosis membrane, the method steps are as follows:

[0037] S1: Stir the anionic surfactant, metal complexing agent, anti-deposition agent, lauroyl diethanolamine, sodium xylene sulfonate and deionized water at 55°C for 25 minutes, and the stirring speed is 600rpm;

[0038] S2: When the temperature of S1 drops to 35°C, add th...

Embodiment 3

[0041] A dirt cleaning agent for reverse osmosis membranes, comprising the following components by weight percentage: fatty alcohol polyoxyethylene ether sodium sulfate 18%, sodium dodecylbenzenesulfonate 28.8%, metal complexing agent 1%, 9.5% of anti-deposition agent, 20% of lauroyl diethanolamine, 8.3% of sodium xylene sulfonate, 3.6% of sodium chloride, 0.4% of sodium sulfate, 0.8% of bactericide and the balance of deionized water.

[0042] The metal complexing agent is triethanolamine; the anti-deposition agent is coconut oil monoethanolamine; the fungicide is DBNPA.

[0043] A preparation method of dirt cleaning agent for reverse osmosis membrane, the method steps are as follows:

[0044] S1: Stir the anionic surfactant, metal complexing agent, anti-sedimentation agent, lauroyl diethanolamine, sodium xylene sulfonate and deionized water at 50°C for 30 min at a stirring speed of 550 rpm;

[0045] S2: When the temperature of S1 drops to 32°C, add the fungicide, stir for 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com