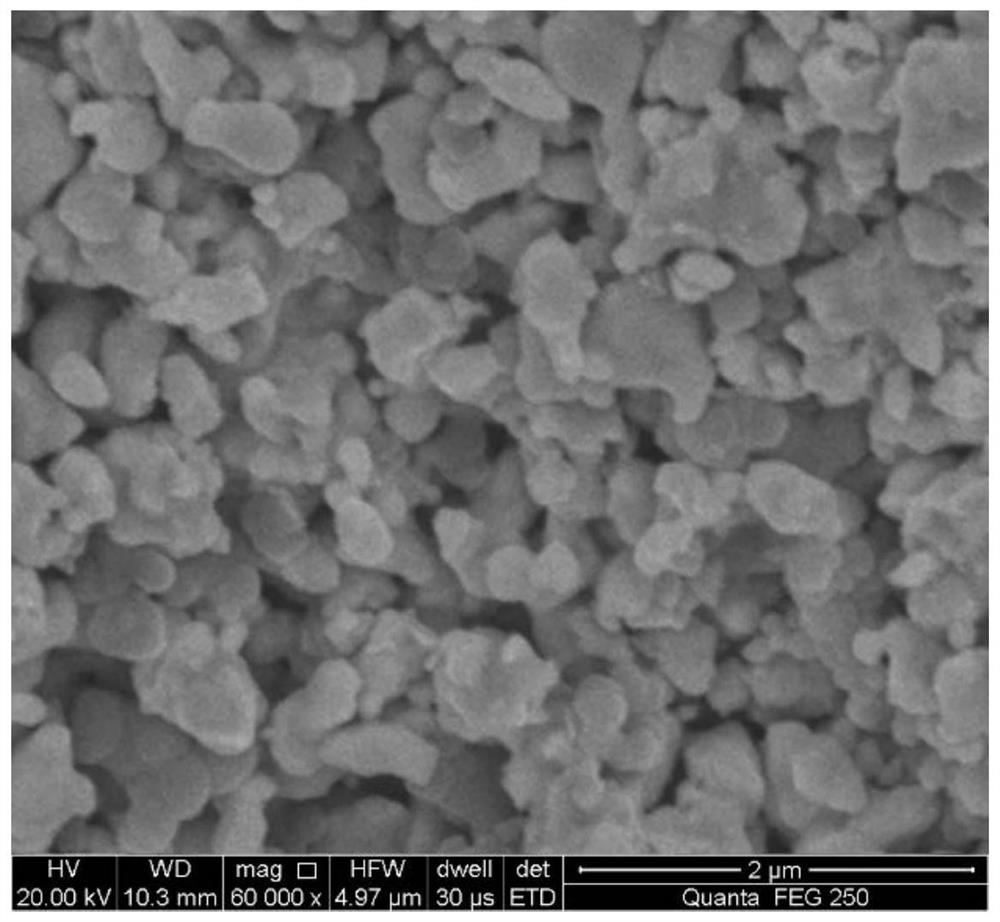

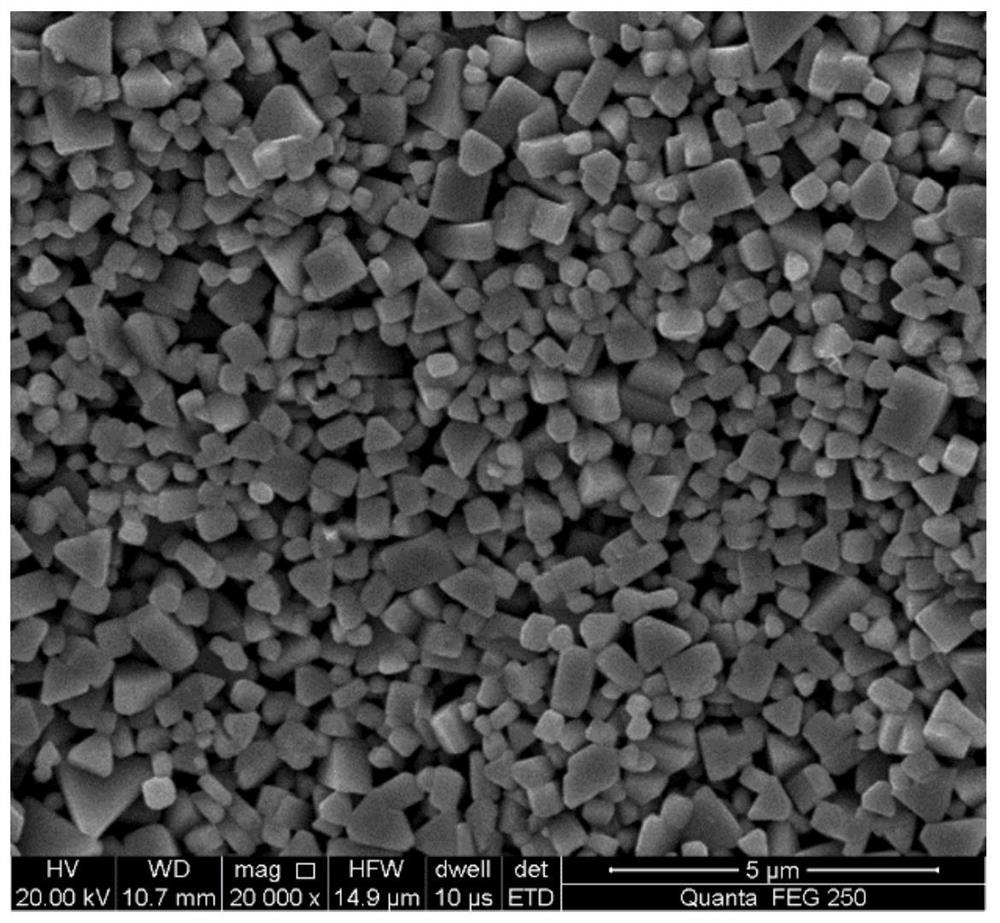

Preparation method of high cobalt nano/ultrafine wc-co composite powder

A composite powder, nanotechnology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of WC grain aggregation and growth, ultrafine grain high cobalt composite powder performance instability, cost High problems, to avoid abnormal oxygen content, easy control of carbon content, and pure phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the high-cobalt nano / ultrafine WC-Co composite powder of the present invention is specifically carried out according to the following steps:

[0043] Step 1, dissolve 150g of cobalt chloride in deionized water, prepare a cobalt salt solution with a concentration of 1mol / L, put it in a stirring container and stir it, and heat it with a constant temperature water bath, the stirring speed is 600r / min, and the temperature of the water bath is 60°C ;

[0044] Step 2, mix soluble tungsten salt, cobalt salt and organic carbon in the aqueous solution evenly, among which ammonium metatungstate is used for soluble tungsten salt, cobalt acetate is used for cobalt salt, and sucrose is used for organic carbon; the precursor powder is obtained by spray drying, spray dried The inlet temperature is 150°C, the outlet temperature is 100°C, and the centrifuge speed is 10000r / min, followed by in-situ reduction carbonization in a fixed bed for one-step carbothermal...

Embodiment 2

[0047] The preparation method of the high-cobalt nano / ultrafine WC-Co composite powder of the present invention is specifically carried out according to the following steps:

[0048] Step 1. Dissolve 70g of cobalt acetate in deionized water to prepare a cobalt salt solution with a concentration of 1mol / L, put it in a stirring container and stir it, and heat it with a constant temperature water bath. The stirring speed is 600r / min, and the temperature of the water bath is 70°C;

[0049] Step 2, after uniformly mixing soluble tungsten salt, cobalt salt and organic carbon in the aqueous solution, ammonium tungstate is used for soluble tungsten salt, cobalt chloride is used for cobalt salt, and glucose is used for organic carbon; the precursor powder is obtained by spray drying, spray The inlet temperature of the drying is 280°C, the outlet temperature is 150°C, and the centrifuge speed is 12000r / min, followed by in-situ reduction carbonization in a fixed bed for one-step carbother...

Embodiment 3

[0052] The preparation method of the high-cobalt nano / ultrafine WC-Co composite powder of the present invention is specifically carried out according to the following steps:

[0053] Step 1. Dissolve 279.5g of cobalt nitrate in deionized water to prepare a cobalt salt solution with a concentration of 1mol / L, put it in a stirring container and stir it, and heat it with a constant temperature water bath. The stirring speed is 600r / min, and the temperature of the water bath is 80°C ;

[0054] Step 2, after mixing the soluble tungsten salt, cobalt salt and organic carbon in the aqueous solution evenly, the soluble tungsten salt is ammonium metatungstate, the cobalt salt is cobalt nitrate, and the organic carbon is maltose; the precursor powder is obtained by spray drying, spray The inlet temperature of drying is 200°C, the outlet temperature is 130°C, and the centrifuge speed is 11000r / min, followed by in-situ reduction carbonization in a fixed bed for one-step carbothermal reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com