A light-weight, high-strength, marine-climate-resistant composite thermal insulation material and its preparation method

A technology for marine climate and thermal insulation materials, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of not being waterproof and oil-proof, completely sealed, and unable to achieve high compressive strength. and other problems, to achieve the effect of improving the compressive strength, the bonding method is simple and reliable, and the production method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

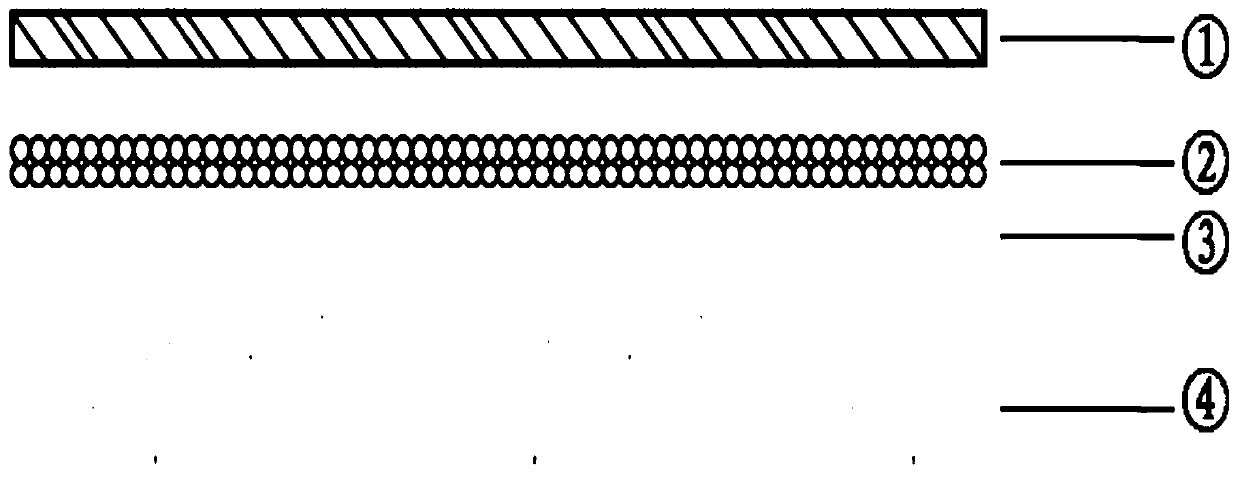

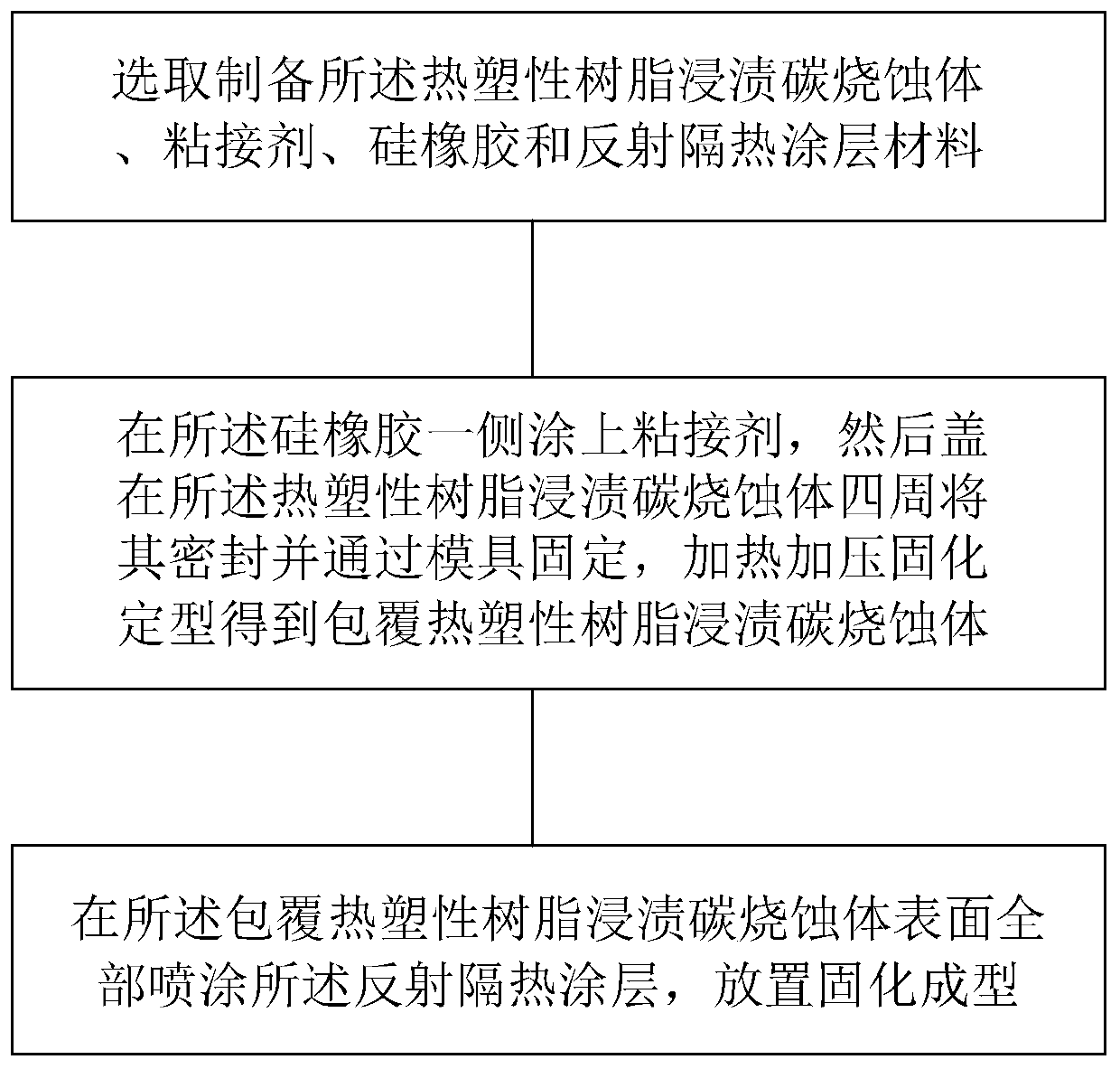

[0027] figure 1 It is a structural schematic diagram of a preferred embodiment of the present invention. It can be seen that a lightweight high-strength composite heat insulating material includes a thermoplastic resin impregnated carbon ablation body 4, an adhesive 3, silicone rubber 2 and a reflective heat insulating coating Layer 1: The thermoplastic resin impregnated carbon ablation body is quartz fiber reinforced resorcinol-formaldehyde type phenolic airgel. The adhesive is heat-resistant silicone adhesive; the silicone rubber is peroxide-cured high-temperature vulcanized silicone rubber, and the base is methylphenyl silicone rubber; the reflective heat-insulating coating is polymethylsiloxane resin-based heat-insulating coating.

[0028] Based on the applicant's consideration of factors such as resin concentration, resin / catalyst ratio, and fiber type, the preferred resorcinol-formaldehyde reactant concentration is 0.5 g / mL, and the curing agent ratio is 6:1. By contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com