Novel water-glossy-maintaining and blooming-free painting pigment and preparation method of same

A pigment and painting technology, applied in the field of moisturizing and non-smudge painting pigments, can solve the problems of acrylic emulsion color, hiding power performance, poor gloss and leveling ability, and affect the appearance of pictures, etc., to achieve water resistance and gloss retention As well as the effects of improved anti-pollution, long storage time, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

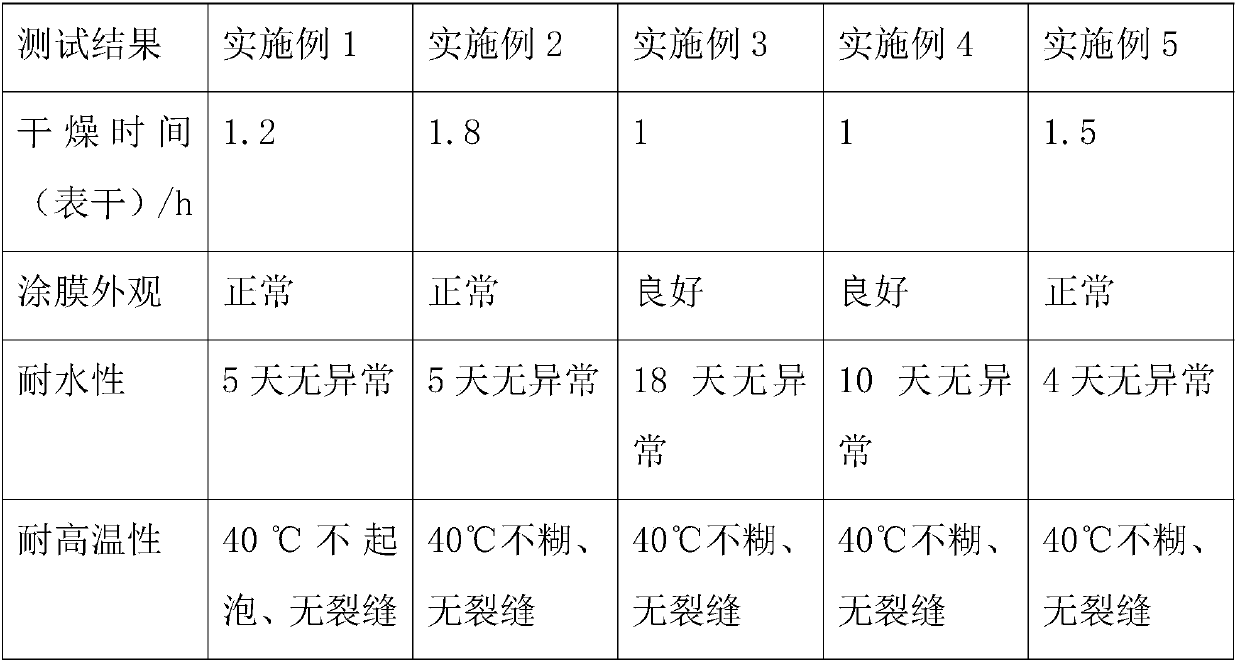

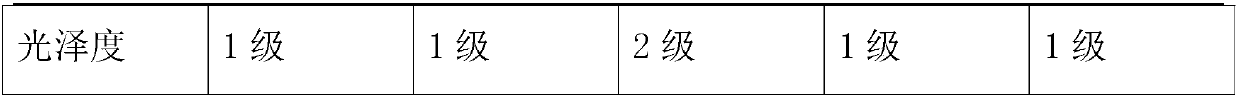

Examples

preparation example Construction

[0031] Preparation method of silicone modified resin:

[0032] 15-30 parts of acrylate monomer, 10-20 parts of vinyl silicone monomer, 2-10 parts of emulsifier, 2-5 parts of initiator and 10-20 parts of water are heated and stirred for emulsification; at a temperature of 80℃ , Stir evenly for 2-3 hours, then add 10-30 parts of glycidyl acrylate dropwise, and serve.

[0033] The preparation method of the graphene slurry:

[0034] Mix and stir silane coupling agent, polyethylene glycol 2000, glycerin and water, add graphene and stir evenly; including the following components by weight: 2-10 parts of graphene, 1-5 parts of polyethylene glycol 2000, 2-5 parts of silane coupling agent, 1-4 parts of glycerin and 5-10 parts of water.

[0035] A method for preparing a new type of moisturizing and non-halting paint, including the following steps:

[0036] (1) Stir and mix acrylic ester emulsion, talc powder, mica powder, polymerization inhibitor, a part of acrylic ester and water in a mixer;

...

Embodiment 1

[0040] A new type of moisturizing and non-halting paint, including the following ingredients in parts by weight (1g per part):

[0041] 5 parts of carbon black, 6 parts of bentonite, 2 parts of hydroquinone, 20 parts of acrylate emulsion, 5 parts of graphene slurry, 0.2 parts of Shanghai Changfeng 9020 dispersant, 0.2 parts of triethanolamine, 0.2 parts of defoamer, PN -23 3 parts, 1 part of talc powder, 8 parts of mica powder, 15 parts of acrylate and 8 parts of water.

[0042] The components in the preparation of acrylate emulsion include: 15 parts of acrylate monomer, 20 parts of vinyl silicone monomer, 30 parts of glycidyl acrylate, 5 parts of emulsifier, 2 parts of initiator and 10 parts of water.

[0043] The components in the preparation of graphene slurry include: 2 parts of graphene, 1 part of polyethylene glycol 2000, 2 parts of silane coupling agent, 4 parts of glycerin, and 5 parts of water.

Embodiment 2

[0045] A new type of moisturizing and non-halting paint, including the following ingredients in parts by weight (1g per part):

[0046] 15 parts of carbon black, 0.5 parts of bentonite, 0.2 parts of hydroquinone, 10 parts of acrylate emulsion, 10 parts of graphene slurry, 1 part of Shanghai Changfeng 9020 dispersant, 1 part of triethanolamine, 1 part of defoamer, PN -23 0.6 parts, 4 parts of talc powder, 2 parts of mica powder, 5 parts of acrylate and 20 parts of water.

[0047] The components in the preparation of acrylate emulsion include: 30 parts of acrylate monomer, 10 parts of vinyl silicone monomer, 10 parts of glycidyl acrylate, 10 parts of emulsifier, 5 parts of initiator and 20 parts of water.

[0048] The components in the preparation of graphene slurry include: 10 parts of graphene, 5 parts of polyethylene glycol 2000, 5 parts of silane coupling agent, 1 part of glycerin, and 10 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com