Electromagnetic shielding coating, and preparation method and application thereof

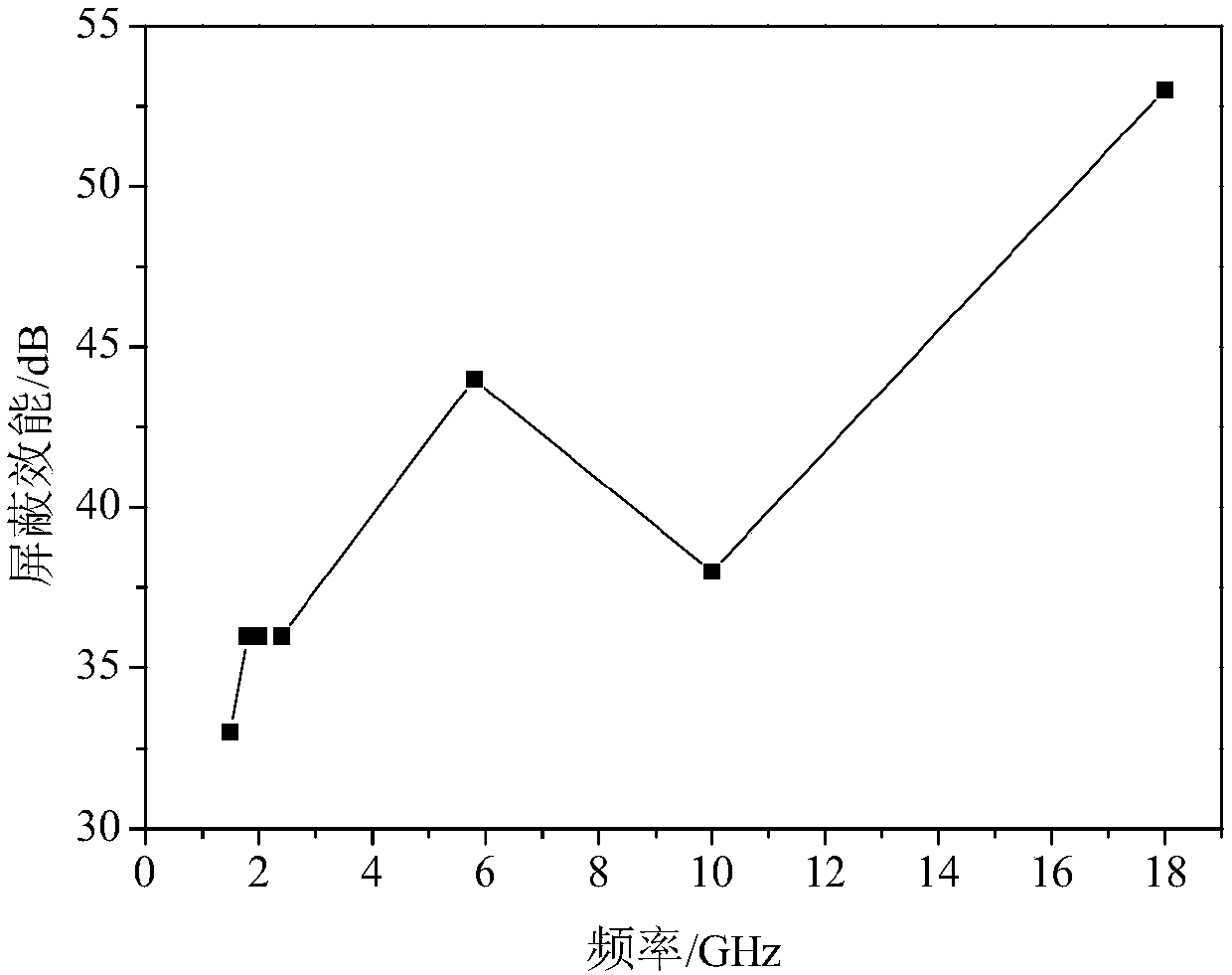

A technology of shielding coatings and electromagnetic shielding, applied in conductive coatings, magnetic field/electric field shielding, antifouling/underwater coatings, etc., can solve the problems of limited magnetic field shielding effectiveness in the middle and low frequency bands, and achieve low density, convenient construction, and response frequency bands wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 A kind of preparation method of ferrite / graphene composite material (electromagnetic shielding filler)

[0039] The present embodiment provides a kind of preparation of ferrite / graphene composite material, comprising:

[0040] (1) Preparation of Fe(NO 3 ) 3 - Aqueous dispersion solution of graphene oxide.

[0041] Fe(NO 3 ) 3 Joining concentration is in the aqueous dispersion liquid of graphene oxide of 5mg / ml, prepares Fe(NO 3 ) 3 A water-dispersible solution with a concentration of 10 mg / ml.

[0042] (2) Melamine sponge impregnated to absorb Fe(NO 3 ) 3 - Graphene oxide solution.

[0043] The melamine sponge was impregnated with Fe(NO 3 ) 3 - After 2 hours in the water dispersion solution of graphene oxide, take it out and dry it at 110° C. for 12 hours.

[0044] (3) High-temperature treatment to prepare lightweight and high-efficiency FeOx / graphene electromagnetic shielding fillers.

[0045] The dried Fe(NO 3 ) 3 -The graphene oxide / sponge...

Embodiment 2

[0047] Embodiment 2 Preparation of an electromagnetic shielding coating

[0048]The present embodiment provides a kind of preparation method of barrier paint, comprising:

[0049] (1) Add 30g of GK570 fluorocarbon resin, 15g of FTH elastic polyester resin, 0.5g of Deqian 6800 additives, 0.5g of BYK110 additives, 0.5g of EFKA2020 additives, and 0.5g of EFKA3777 additives into 7g of mixed solvent and mix, stirring , slowly add 30 g of the electromagnetic shielding filler obtained in Example 1, after the dispersion is uniform, grind to a fineness of 40 μm, add the remaining 3 g of mixed solvent, adjust the viscosity of the system to 800-1000 cp, filter, and discharge to obtain the first component;

[0050] Described mixed solvent is made up of xylene 3.5g, ethyl acetate 3g, cyclohexanone 3.5g.

[0051] (2) A, B components (isocyanate N3390) according to the molar ratio (-OH) 甲 :(-NCO) 乙 = 1:1 mixing, stirring evenly, that is, the electromagnetic shielding coating is prepared. ...

Embodiment 3

[0053] The present embodiment provides a kind of preparation method of shielding coating similar to embodiment 2, and difference is only wherein the formula of first component is as follows:

[0054] GK570 fluorocarbon resin 25g, FTH elastic polyester resin 25g, 6800 additive 0.3g, BYK110 additive 0.6g, EFKA2020 additive 0.3g, EFKA3777 additive 0.6g, mixed solvent 5g, electromagnetic shielding filler 20g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic saturation | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com