C5/C6 olefin polymerization catalysis technology method of light gasoline

A technology of carbon hexaolefins and process methods, which is applied in the field of olefin catalytic cracking superimposition process of light gasoline, and achieves the effects of wide application fields, high-efficiency activity and stability, and high-efficiency superposition catalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

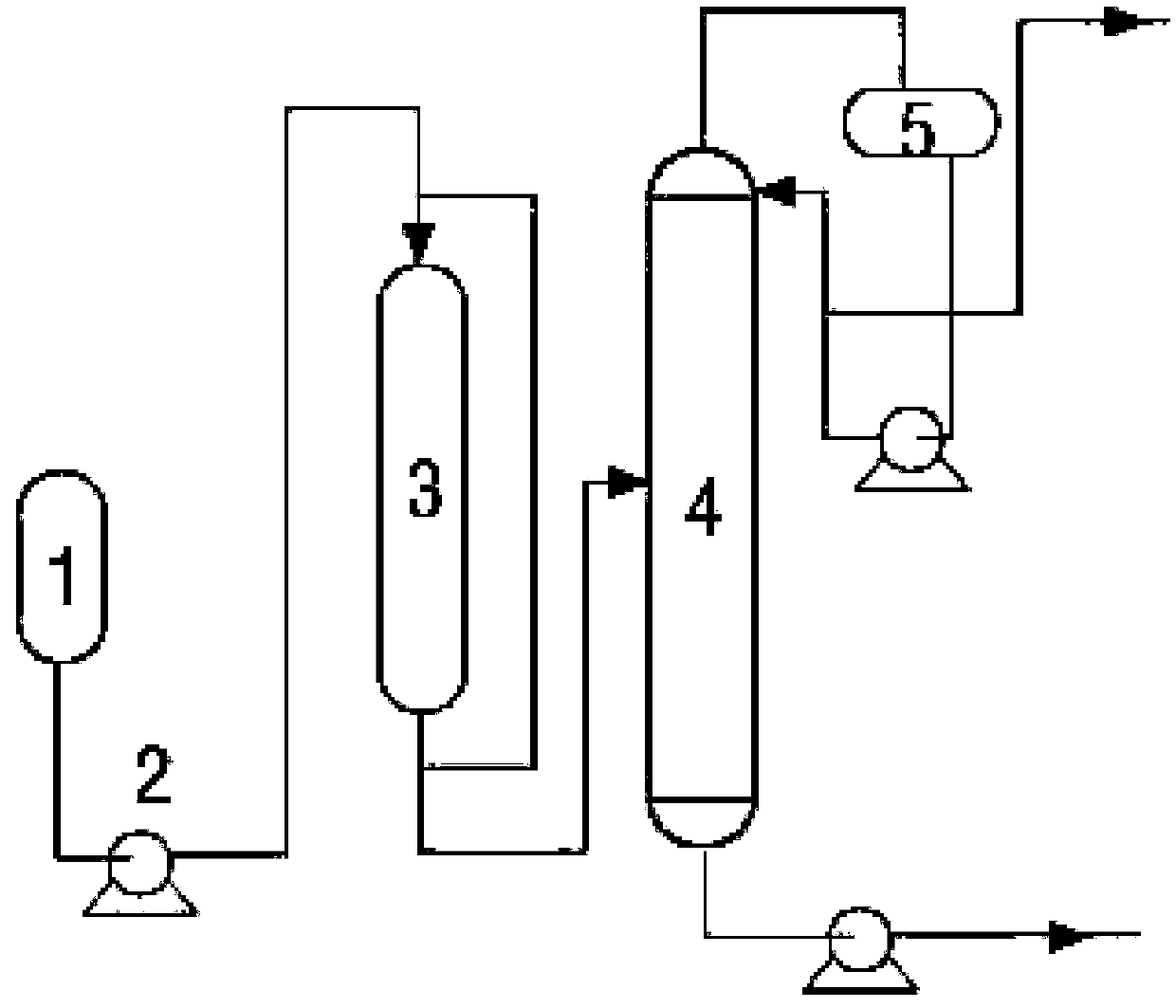

Image

Examples

Embodiment Construction

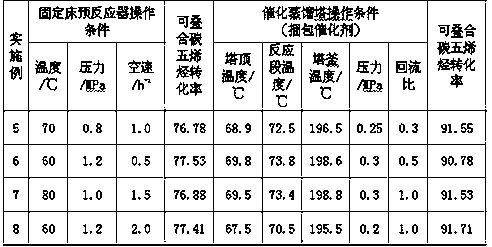

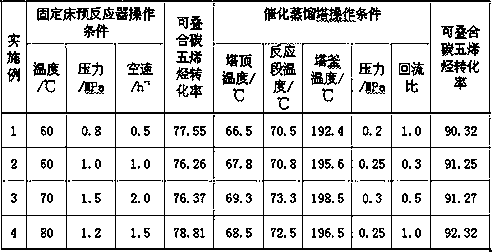

[0025] The patent application will be further described below through the following specific examples, and the essence of the technical solution content of the patent application can be fully understood through these examples, but the present invention is not limited to these examples.

[0026] The strong-acid cationic resin catalysts used in the following examples are obtained from styrene and divinylbenzene monomers, suspended copolymerized and copolymerized white balls under the action of porogens and surfactants, followed by pore purification and sulfonation. The obtained strong-acid cationic resin catalyst of each following specific embodiment is respectively:

[0027] Catalyst C-1

[0028] ①. Copolymerization:

[0029] In a stainless steel stirred tank equipped with a reflux condensing device, add 2000g of water and a surfactant, heat with stirring, and completely dissolve to obtain an aqueous phase; the surfactant includes 20g of triethanolamine soap, 20g of sulfated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com