Dip-coating glue solution for fast curing automobile filter paper, automobile filter paper adopting same and preparation method

A fast-curing, automotive technology, applied in the field of filter paper, can solve the problems of prolonged production process of filter elements, long curing time, and high brittleness of filter paper, and achieve the effect of short curing time, reducing curing time and promoting curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

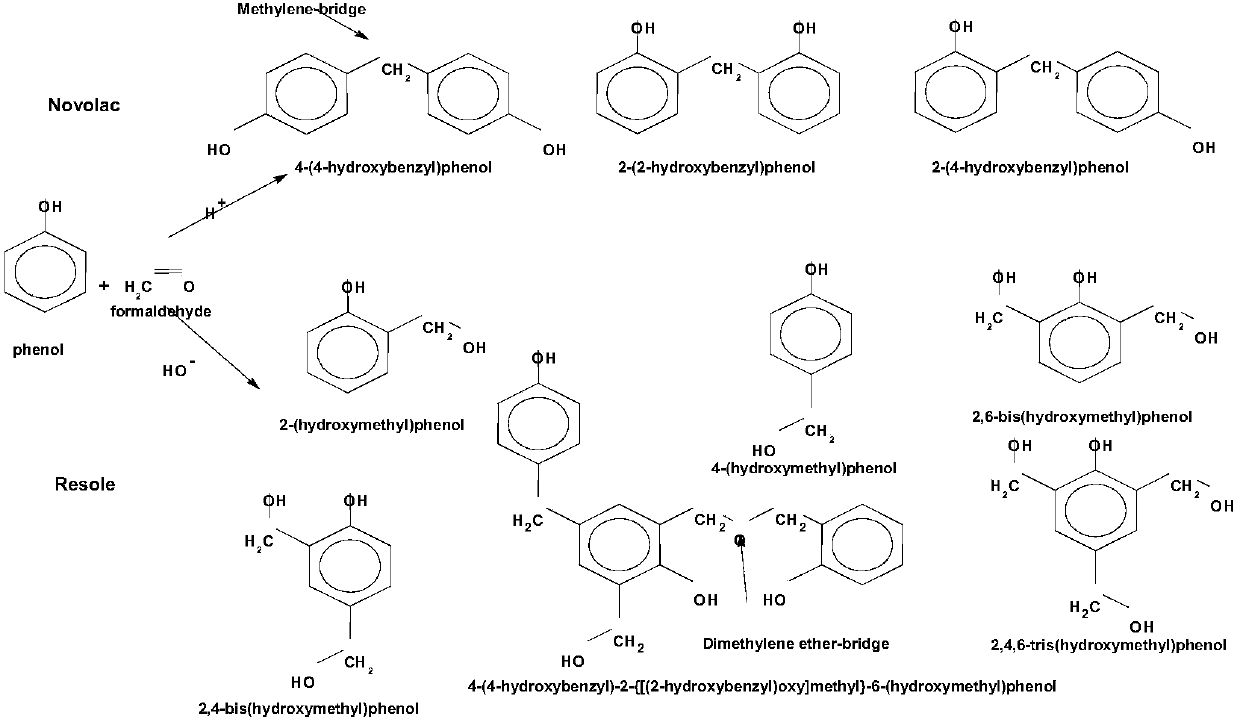

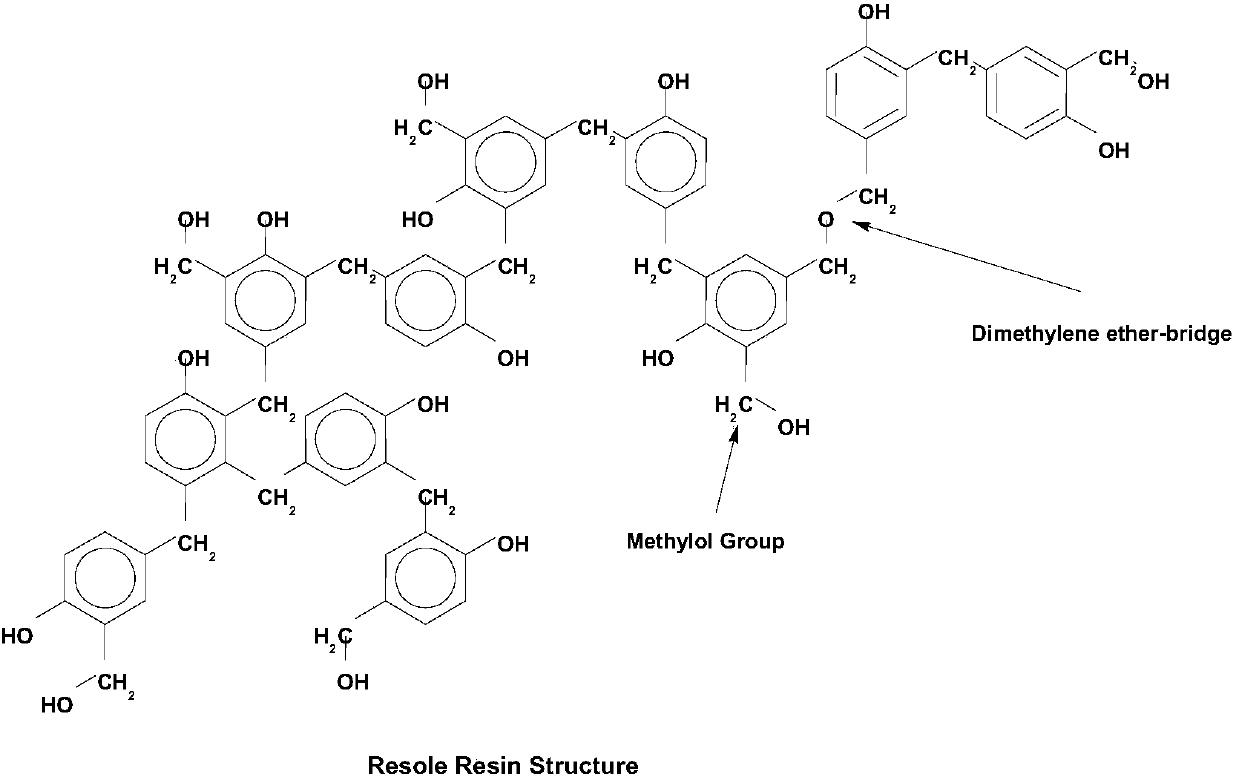

Method used

Image

Examples

Embodiment 1

[0036] A kind of quick-curing dip-coating glue for automobile filter paper, the composition of raw materials is as follows:

[0037] 100kg of phenolic resin, 10kg of curing accelerator, and 190kg of methanol.

[0038] Take the phenolic resin and add it to methanol, stir at room temperature for 3-5 minutes, then add the curing accelerator and stir for 5-8 minutes to obtain a fast-curing dip coating glue for automobile filter paper.

[0039] A kind of preparation method of rapid solidification automobile filter paper, comprises steps as follows:

[0040] (1) Base paper preparation: Weigh the mixed fibers composed of coniferous pulp fibers and broad-leaved pulp fibers and soak for 40-50 minutes to disintegrate. After disintegration, add water to dilute for disintegration. The base paper with a porous and loose structure is produced through inclined wire paper machine papermaking;

[0041] (2) Coating and curing: Dip-coat the dip-coating glue on the base paper prepared in step (...

Embodiment 2

[0044] A kind of fast solidification automotive filter paper dip coating glue, with embodiment 1.

[0045] A kind of preparation method of rapid solidification automobile filter paper, comprises steps as follows:

[0046] (1) Base paper preparation: Weigh the mixed fibers composed of coniferous pulp fibers and broad-leaved pulp fibers and soak for 40-50 minutes to disintegrate. After disintegration, add water to dilute for disintegration. The base paper with a porous and loose structure is produced through inclined wire paper machine papermaking;

[0047] (2) Coating and curing: Dip-coat the dip-coating glue on the base paper prepared in step (1) by means of double-roller metering film transfer, and obtain fast-curing automotive filter paper after curing. Curing temperature: 1# section temperature 85°C The temperature of 2# section is 125°C; the temperature of 3# section is 155°C; the temperature of 4# section is 185°C;

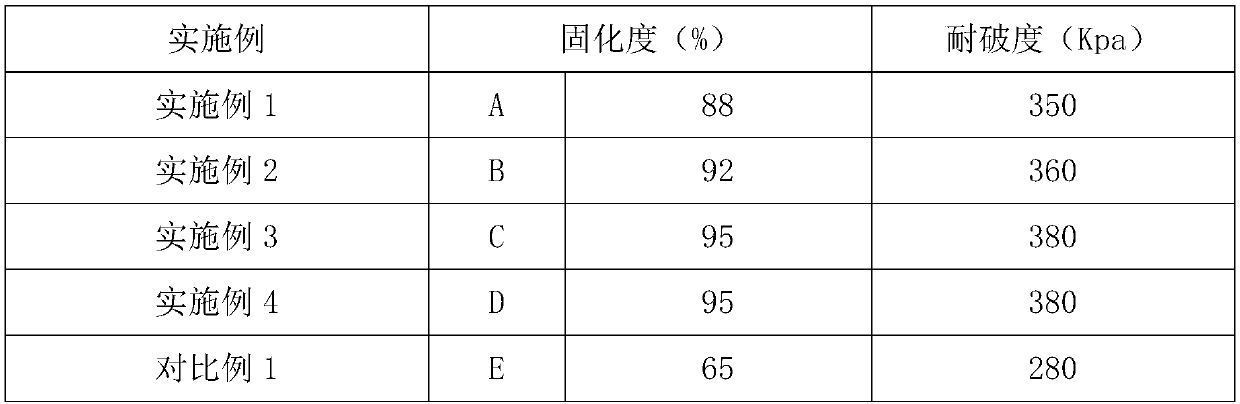

[0048] The degree of curing of the obtained cured aut...

Embodiment 3

[0050] A kind of fast solidification automotive filter paper dip coating glue, with embodiment 1.

[0051] A kind of preparation method of rapid solidification automobile filter paper, comprises steps as follows:

[0052] (1) Base paper preparation: Weigh the mixed fibers composed of coniferous pulp fibers and broad-leaved pulp fibers and soak for 40-50 minutes to disintegrate. After disintegration, add water to dilute for disintegration. The base paper with a porous and loose structure is produced through inclined wire paper machine papermaking;

[0053] (2) Coating and curing: Dip-coat the dip-coating glue on the base paper prepared in step (1) by means of double-roller metering film transfer, and obtain fast-curing automotive filter paper after curing. Curing temperature: 1# section temperature 85°C The temperature of 2# section is 125°C; the temperature of 3# section is 155°C; the temperature of 4# section is 185°C;

[0054] The degree of curing of the obtained cured aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com