An optimum imaging plane adjusting and calibrating method based on a CCD coherence factor detection apparatus

A detection device and coherence factor technology, which is applied in the photoplate-making process exposure device, the photo-plate-making process of the pattern surface, optics, etc., can solve the problems that the calibration process is difficult to achieve, and the production process cannot meet the requirements of real-time measurement of the lighting system. Achieve the effects of shortening the photosensitive time, high reusability, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It is necessary to point out here that the embodiments described below are exemplary, and are intended to further explain the present invention, but can not be interpreted as limiting the protection scope of the present invention. Making some non-essential improvements and adjustments still belongs to the protection scope of the present invention.

[0036] The specific steps of an optimal imaging plane adjustment method based on a CCD coherence factor detection device proposed by the present invention are as follows:

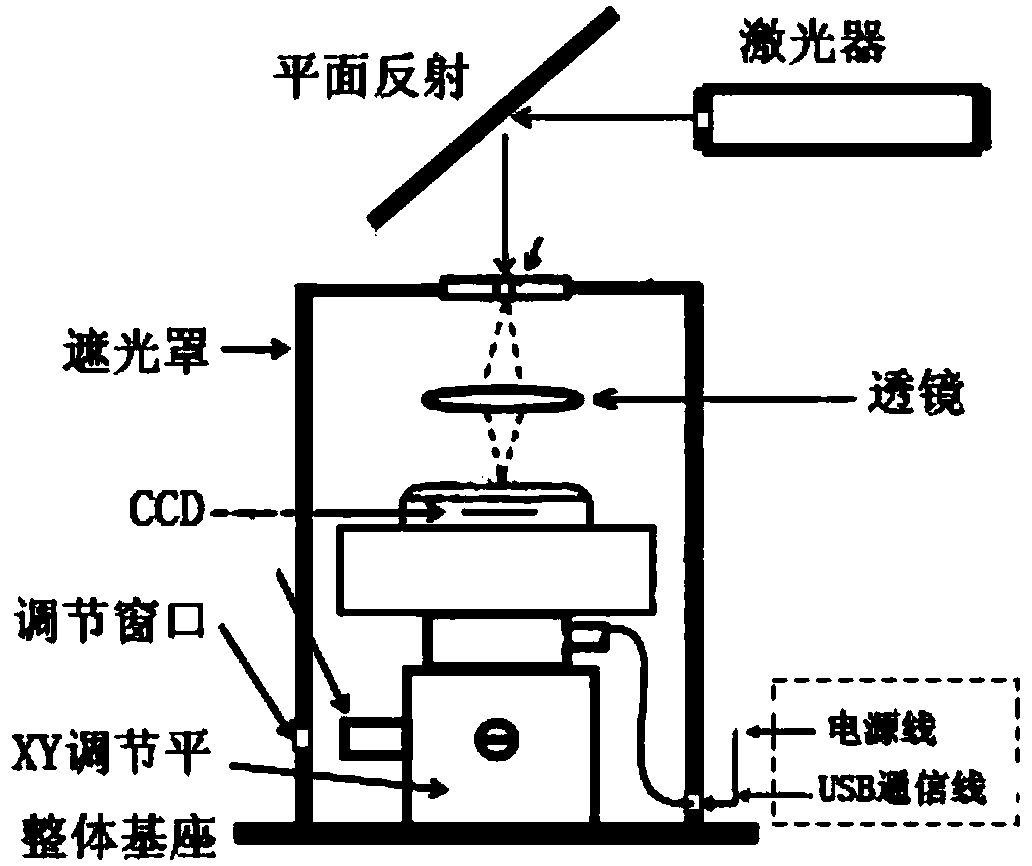

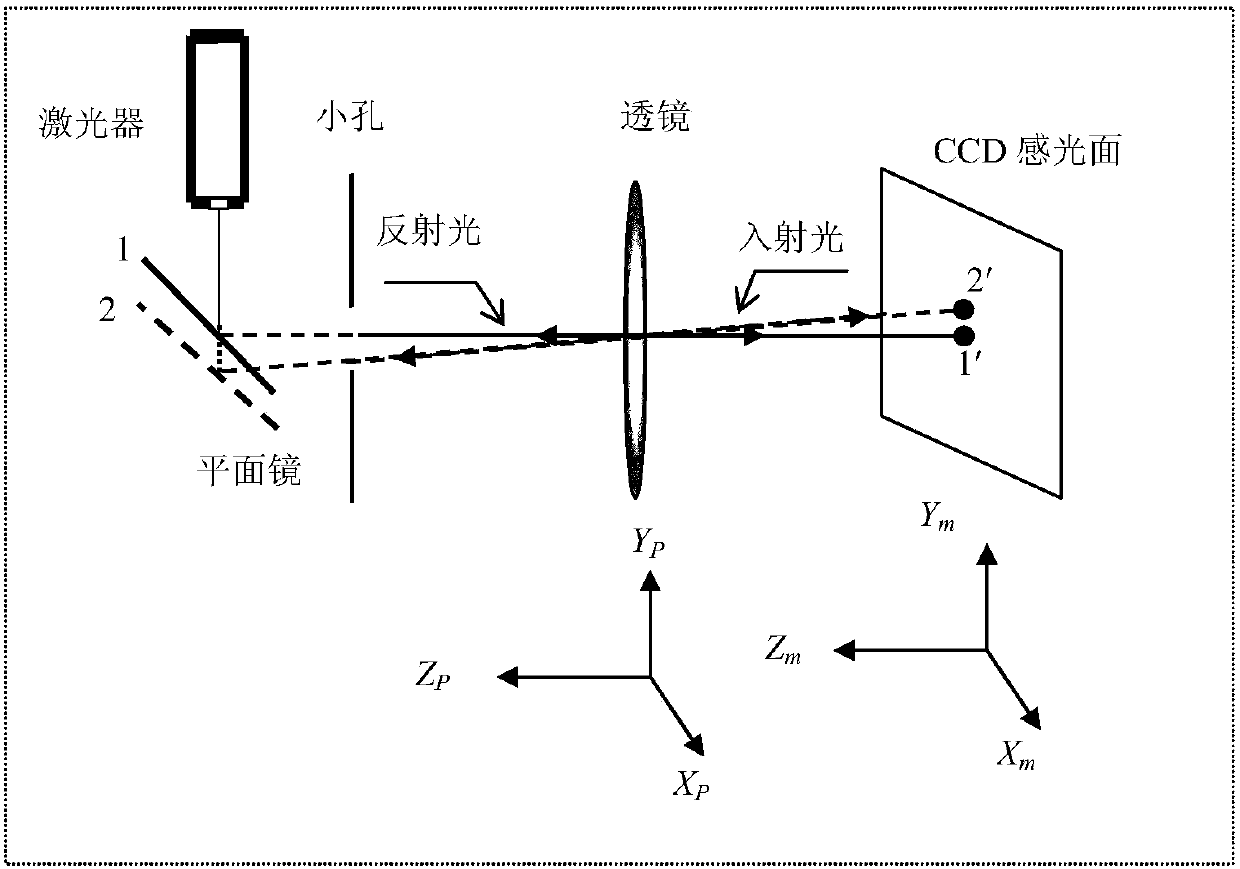

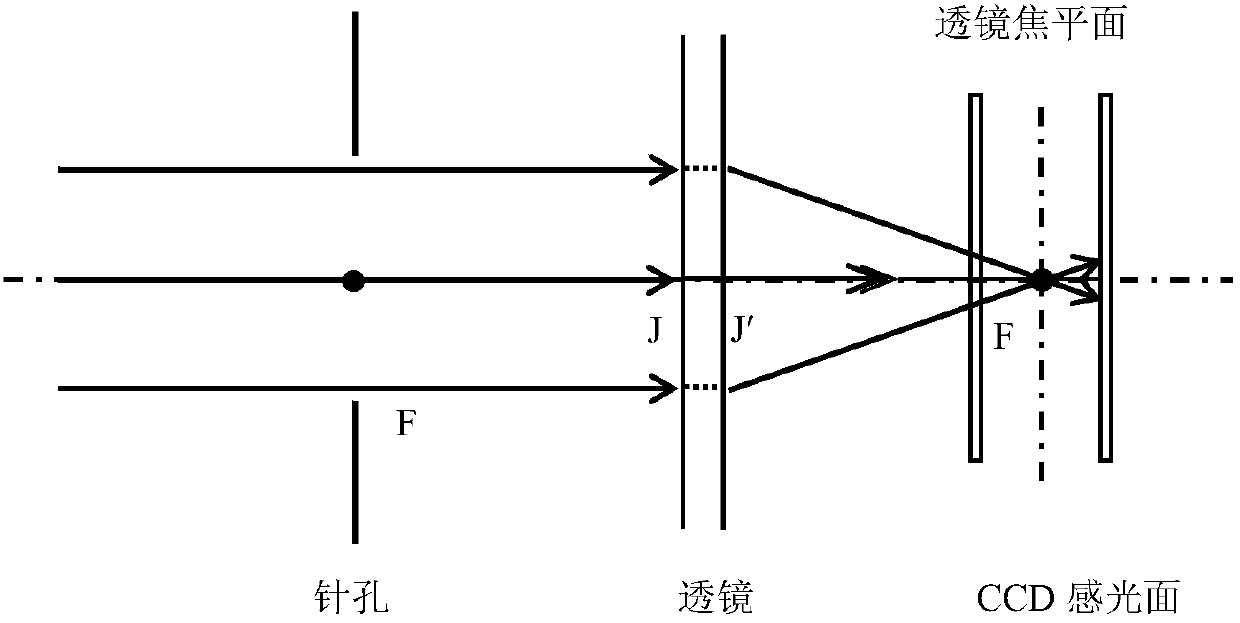

[0037] 1. Build the device for the detection system, such as figure 1 shown. The device consists of a laser, a mirror, a pinhole, a lens group, a manual X-Y displacement platform and a CCD. After calibration, the laser beam is inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com