IC carrier board

A carrier board and substrate technology, applied in the field of IC carrier boards, can solve the problems of difficult heat dissipation of IC carrier boards, achieve excellent flame retardancy and salt spray resistance, solve the effects of difficult heat dissipation, and internal structure protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

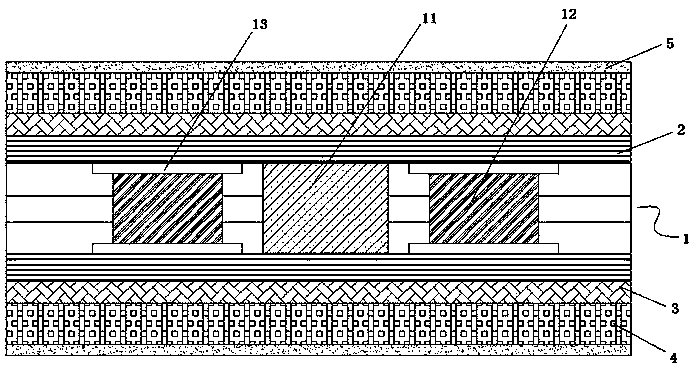

[0020] A kind of IC carrier board, it is characterized in that, comprises ceramic substrate 1, and described ceramic substrate is provided with first IC substrate 11, second IC substrate 12, flexible circuit board 13, and described first IC substrate is arranged on ceramic substrate In the central area, the second IC substrate is symmetrically arranged on both sides of the first IC substrate, and the flexible circuit board is symmetrically arranged on the upper and lower ends of the second IC substrate; layer 2, a second heat dissipation layer 3 is provided on one side of the first heat dissipation layer, an insulating layer 4 is provided on one side of the second heat dissipation layer, and a protective coating 5 is provided on the surface of the insulating layer.

[0021] Further, the first heat dissipation layer 2 is a metal copper heat dissipation layer.

[0022] Further, the second heat dissipation layer 3 is an aramid fiber layer.

Embodiment 2

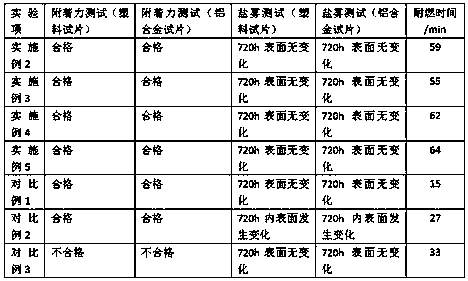

[0026] This embodiment provides an IC carrier with a structure consistent with that of Embodiment 1. The difference is that the protective coating 5 includes the following components in parts by weight: maleic acid resin 23, methyl methacrylate 13, Epoxy resin 7, azobisisobutyronitrile 6, polyethylene glycol 13, calcium stearate 11, sodium alginate 17, alumina ceramic powder 19, tributyl phosphate 5, dodecyl alcohol ester 7, Polyimide hollow microspheres 36, 1,3-diaminopentane 8, diethanolamine 15, distilled water 62.

[0027] The preparation method of the protective coating in the present embodiment is: the preparation method of coating of the present invention is: maleic acid resin, methyl methacrylate, epoxy resin, azobisisobutyronitrile, polyethylene glycol, After dissolving 1,3-diaminopentane, shake well, heat the shaken solution to 55-65°C, and stir at 150r / min for 45-65min to obtain a mixed solution; mix the remaining components in parts by mass to Disperse at a disper...

Embodiment 3

[0029] This embodiment provides an IC carrier with a structure consistent with that of Embodiment 1. The difference is that the protective coating 5 includes the following components in parts by weight: maleic acid resin 34, methyl methacrylate 21, Epoxy resin 13, azobisisobutyronitrile 13, polyethylene glycol 19, calcium stearate 17, sodium alginate 29, alumina ceramic powder 48, tributyl phosphate 9, dodecyl alcohol ester 11, Polyimide hollow microspheres 53, 1,3-diaminopentane 15, diethanolamine 24, distilled water 89.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com