A method of preparing a tricobalt tetroxide material loaded by nitrogen-doped exfoliated carbon nanotubes

A technology of cobalt tetroxide and carbon nanotubes, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost of precious metals, limited precious metals, and low resource reserves, and achieve the effect of easy acquisition and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

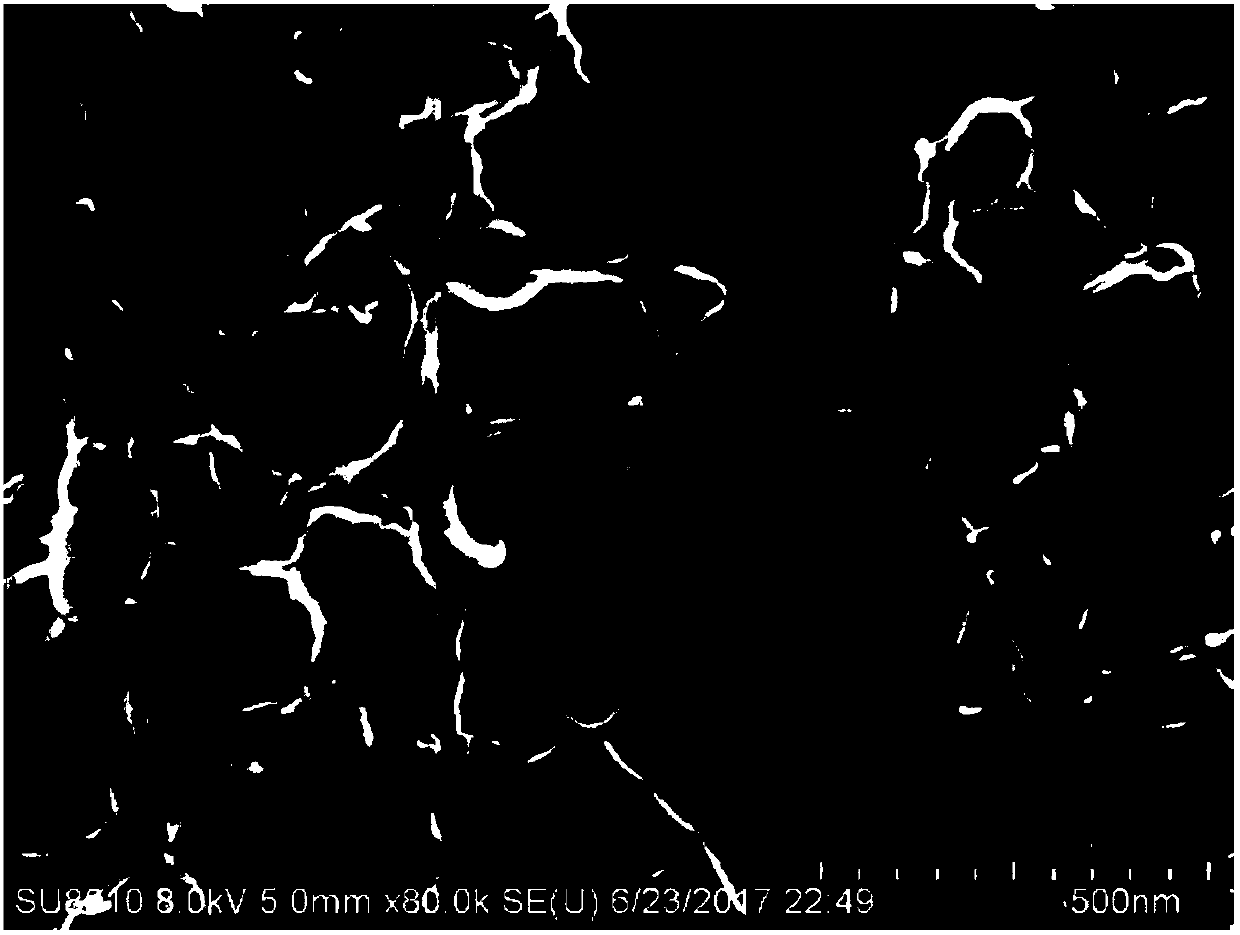

Image

Examples

preparation example Construction

[0046] The present invention proposes a method for preparing a nitrogen-doped exfoliated carbon nanotube-supported cobalt tetroxide material, comprising the following steps:

[0047] Step S1: preparing exfoliated carbon nanotubes;

[0048] Step S2: preparing a nitrogen-doped exfoliated carbon nanotube-supported cobalt tetroxide material.

[0049] Wherein, above-mentioned step S1 comprises the following steps:

[0050] Step S11: Pour concentrated acid into a flask containing carbon nanotubes, stir and mix thoroughly to obtain a dispersion solution;

[0051] Step S12: Slowly add a strong oxidizing agent to the dispersion solution in Step S11, and stir for a certain period of time to obtain a mixture;

[0052] Step S13: heating the mixture in step S12 in a water bath for a period of time and keeping stirring;

[0053] Step S14: adding hydrogen peroxide and deionized water to the mixture in step S13 to obtain a dispersion;

[0054] Step S15: Repeatedly centrifuging and washing...

Embodiment 1

[0075] In the embodiment of the present invention, when preparing exfoliated carbon nanotubes, pour 150mL of concentrated sulfuric acid into a 500mL round bottom flask containing 1g of multi-walled carbon nanotubes, stir with a magnetic stirrer to obtain a dispersion solution, and then slowly add 6g of potassium permanganate was stirred for 30 minutes to obtain a purple-red mixture. The obtained purple-red mixture was placed in a water bath at 80°C and heated for 2 hours, and stirring was required during the heating in the water bath.

[0076] Then, 20 mL of hydrogen peroxide and ice cubes with a volume of 300 mL were slowly added to the mixture heated in a water bath to obtain a yellow solution. Then the yellow solution is centrifuged, washed with 10% hydrochloric acid and secondary water for several times and then centrifuged, and finally freeze-dried to obtain the exfoliated carbon nanotubes.

[0077]In addition, when preparing nitrogen-doped exfoliated carbon nanotubes loa...

Embodiment 2

[0079] When preparing exfoliated carbon nanotubes in the embodiment of the present invention, pour 300mL of concentrated sulfuric acid into a 500mL round-bottomed flask equipped with 2g of multi-walled carbon nanotubes, stir with a magnetic stirrer to obtain a dispersion solution, and then slowly add Add 6g of potassium permanganate, and stir for 30 minutes to obtain a purple-red mixture. Place the obtained purple-red mixture in a water bath at 80° C. for 2 hours and keep stirring, which needs to be kept stirring during the heating in the water bath.

[0080] Then slowly add 20mL of hydrogen peroxide and ice cubes with a volume of 500mL to the mixture heated in a water bath to obtain a yellow solution, then centrifuge the yellow solution, and then wash it with 10% hydrochloric acid and secondary water. centrifuged, and finally freeze-dried to obtain exfoliated carbon nanotubes.

[0081] In addition, when preparing nitrogen-doped exfoliated carbon nanotubes loaded with cobalt t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com