Broad spectral response g-C3N4/Ta3N5 composite photocatalytic material and preparation method and application thereof

A composite photocatalysis, g-c3n4 technology, applied in chemical instruments and methods, physical/chemical process catalysts, light water/sewage treatment, etc., can solve the problems of wide band gap and limited application, and achieve oxidation inhibition and excellent treatment , the effect of loose preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

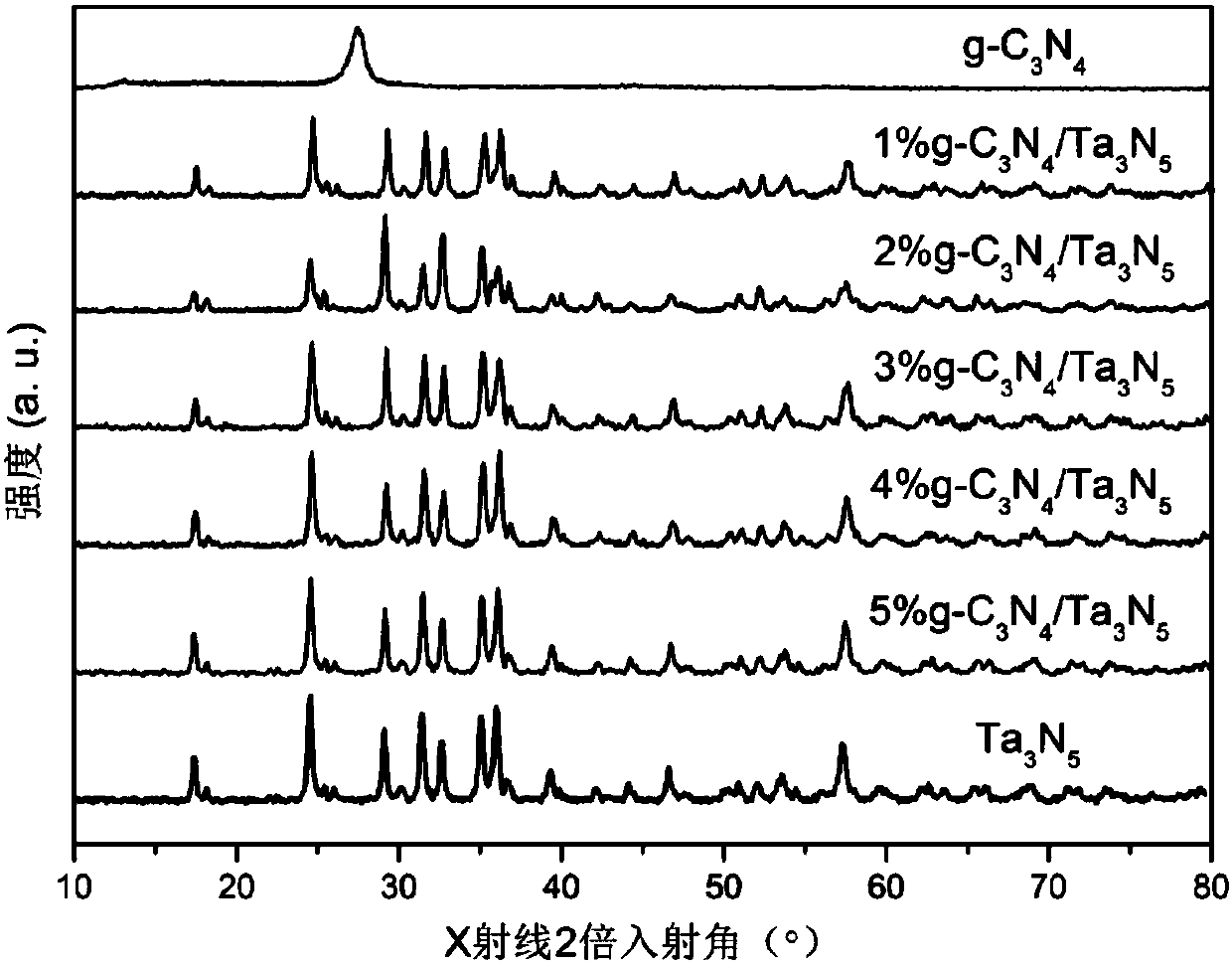

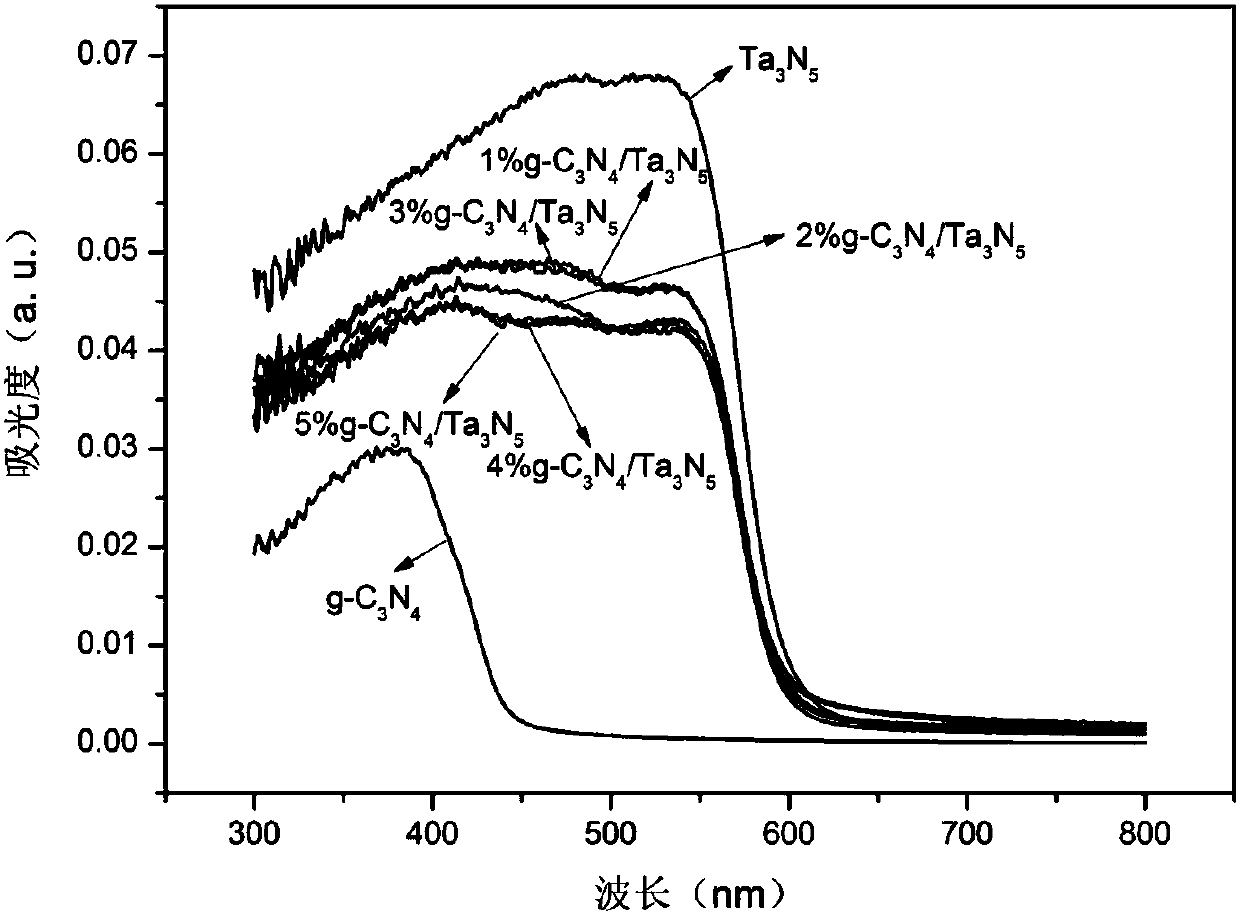

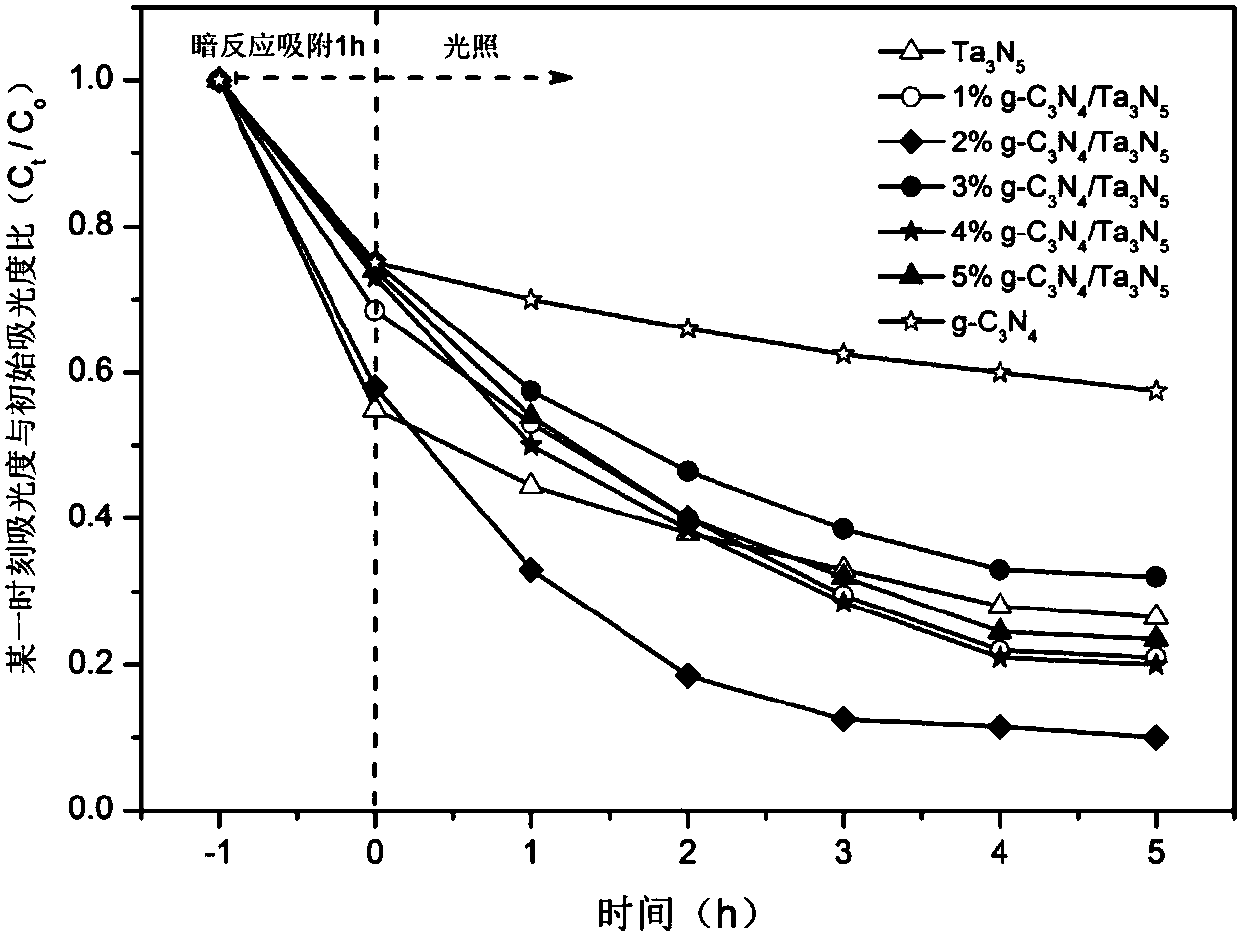

[0027] A broad spectral response g-C 3 N 4 / Ta3 N 5 The preparation method of composite photocatalytic material comprises the following steps:

[0028] (1) Preparation of g-C by thermal polymerization 3 N 4

[0029] Weigh 1g of melamine into an alumina crucible and cover it, place it in a muffle furnace and heat it at a heating rate of 3°C / min, the calcination temperature is 550°C, the calcination time is 4h in air atmosphere, and naturally cool to room temperature to obtain yellow g-C 3 N 4 powder;

[0030] (2), using NH 3 Preparation of Ta by Direct Nitriding 3 N 5

[0031] Weigh 1g Ta 2 o 5 , put it into an alumina crucible, place it in a tube furnace, and continuously feed NH at a flow rate of 500mL / min 3 , heated at a heating rate of 10°C / min, the nitriding temperature was 850°C, the nitriding time was 10h, and naturally cooled to room temperature to obtain brown-red Ta 3 N 5 ;

[0032] (3), using ball milling method and in NH 3 Preparation of g-C by anne...

Embodiment 2

[0036] A broad spectral response g-C 3 N 4 / Ta 3 N 5 The preparation method of composite photocatalytic material comprises the following steps:

[0037] (1) Preparation of g-C by thermal polymerization 3 N 4

[0038] Operation process is with embodiment 1;

[0039] (2), using NH 3 Preparation of Ta by Direct Nitriding 3 N 5

[0040] Operation process is with embodiment 1;

[0041] (3), using ball milling method and in NH 3 Preparation of g-C by annealing in atmosphere 3 N 4 / Ta 3 N 5 composite photocatalytic material

[0042] Weigh the prepared 0.02g g-C 3 N 4 and 0.98g Ta 3 N 5 , add an appropriate amount of absolute ethanol, fully grind the grinding time for 1h, put the ground composite material into an alumina crucible, place it in a tube furnace, and continuously feed NH at a flow rate of 80mL / min 3 , heated at a heating rate of 10°C / min, the annealing temperature was 400°C, annealed for 2 hours, and naturally cooled to room temperature to obtain 2% g-...

Embodiment 3

[0045] A broad spectral response g-C 3 N 4 / Ta 3 N 5 The preparation method of composite photocatalytic material comprises the following steps:

[0046] (1) Preparation of g-C by thermal polymerization 3 N 4

[0047] Operation process is with embodiment 1;

[0048] (2), using NH 3 Preparation of Ta by Direct Nitriding 3 N 5

[0049] Operation process is with embodiment 1;

[0050] (3), using ball milling method and in NH 3 Preparation of g-C by annealing in atmosphere 3 N 4 / Ta 3 N 5 composite photocatalytic material

[0051] Weigh the prepared 0.03g g-C 3 N 4 and 0.97g Ta 3 N 5 , add an appropriate amount of absolute ethanol, fully grind the grinding time for 1h, put the ground composite material into an alumina crucible, place it in a tube furnace, and continuously feed NH at a flow rate of 80mL / min 3 , heated at a heating rate of 10°C / min, the annealing temperature was 400°C, annealed for 2 hours, and naturally cooled to room temperature to obtain 3% g-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com