Desulfurization industrial waste water treatment method

A treatment method and technology for industrial wastewater, which are applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of the power industry, the complex composition of desulfurization wastewater, and the poor drug compatibility. To achieve the effect of improving the overall applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

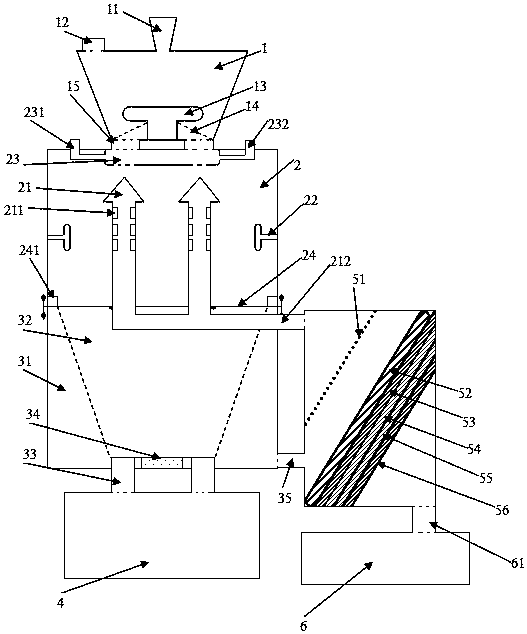

[0037] A desulfurization industrial wastewater treatment method, the treatment method uses desulfurization industrial wastewater treatment equipment, the equipment includes a neutralization tank, a sedimentation flocculation chamber, a mud discharge chamber, a plate and frame filter press, a sewage treatment chamber and a water storage tank.

[0038] The neutralization tank includes a neutralization tank shell, a desulfurization wastewater inlet, a neutralizer inlet, a stirring shaft, a neutralization filter plate, and a neutralization tank outlet; A desulfurization wastewater inlet is provided, a neutralizer inlet is provided on the top side, and a stirring shaft is provided at the inner bottom of the neutralization tank shell. A plurality of blades, extending from the connection between the stirring shaft and the blades to the outermost side of the bottom of the neutralization box shell, a neutralization filter plate (set in the shape of an inverted funnel) is provided, and a...

Embodiment 2

[0057] A desulfurization industrial wastewater treatment method, the treatment method uses desulfurization industrial wastewater treatment equipment, the equipment includes a neutralization tank, a sedimentation flocculation chamber, a mud discharge chamber, a plate and frame filter press, a sewage treatment chamber and a water storage tank.

[0058] The neutralization tank includes a neutralization tank shell, a desulfurization wastewater inlet, a neutralizer inlet, a stirring shaft, a neutralization filter plate, and a neutralization tank outlet; A desulfurization wastewater inlet is provided, a neutralizer inlet is provided on the top side, and a stirring shaft is provided at the inner bottom of the neutralization tank shell. A plurality of blades, extending from the connection between the stirring shaft and the blades to the outermost side of the bottom of the neutralization box shell, a neutralization filter plate (set in the shape of an inverted funnel) is provided, and a...

Embodiment 3

[0078] A desulfurization industrial wastewater treatment method, the treatment method uses desulfurization industrial wastewater treatment equipment, the equipment includes a neutralization tank, a sedimentation flocculation chamber, a mud discharge chamber, a plate and frame filter press, a sewage treatment chamber and a water storage tank.

[0079] The neutralization tank includes a neutralization tank shell, a desulfurization wastewater inlet, a neutralizer inlet, a stirring shaft, a neutralization filter plate, and a neutralization tank outlet; A desulfurization wastewater inlet is provided, a neutralizer inlet is provided on the top side, and a stirring shaft is provided at the inner bottom of the neutralization tank shell. A plurality of blades, extending from the connection between the stirring shaft and the blades to the outermost side of the bottom of the neutralization box shell, a neutralization filter plate (set in the shape of an inverted funnel) is provided, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com