Gas channeling control cement slurry system applicable to shale gas well cementation and preparation method thereof

A technology for preventing gas channeling and cement slurry, applied in the field of oil drilling and cementing, can solve problems such as poor compatibility of rubber powder and influence on the stability of cement slurry, achieve good ability to control water loss, protect from pollution, The effect of improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

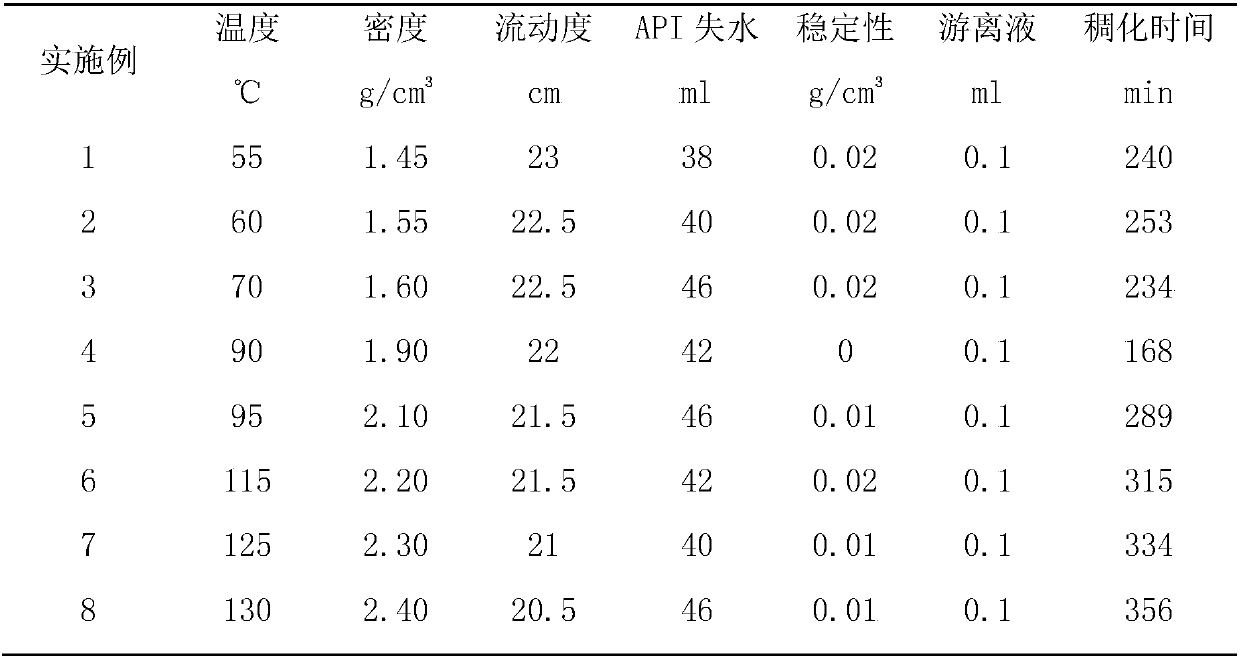

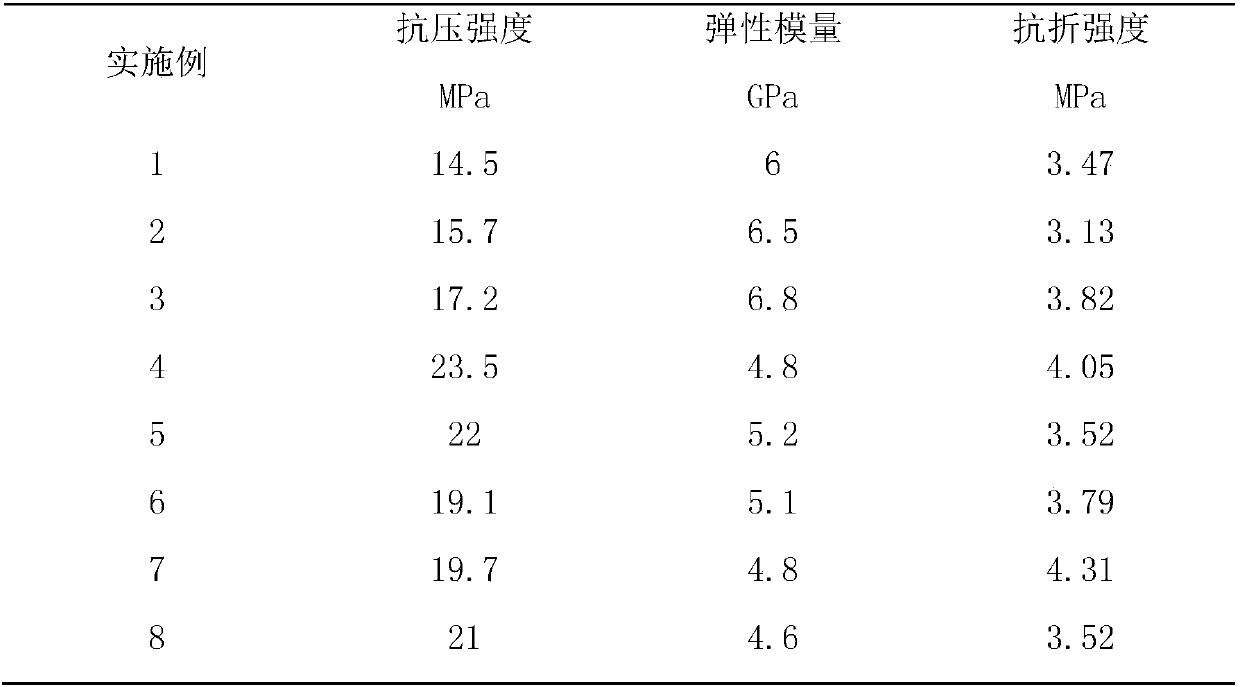

Examples

Embodiment 1

[0025] An anti-gas channeling cement slurry system suitable for shale gas cementing, comprising the following raw materials in parts by weight: 100 parts of G grade oil well cement, 73 parts of fresh water, 25 parts of lightening agent, 0.5 part of G403 oil well cement toughening agent, 12 parts of stabilizer, 2.5 parts of G33S oil well cement fluid loss reducer, 1.4 parts of GH-9 oil well cement retarder, 2.5 parts of G401 oil well cement expansion agent, 0.3 parts of USZ oil well cement drag reducer, 0.2 parts of XP-1 defoamer share.

[0026] The preparation method of the anti-gas channeling cement slurry system applicable to shale gas cementing comprises the following steps:

[0027] ① Weigh G grade oil well cement, lightening agent, G403 oil well cement toughening agent, stabilizer, G33S oil well cement fluid loss reducer, G401 oil well cement expansion agent, USZ oil well cement drag reducer, mix well and set aside;

[0028] ②Put fresh water, GH-9 oil well cement retarde...

Embodiment 2

[0031] An anti-gas channeling cement slurry system suitable for shale gas cementing, including the following raw materials in parts by weight: 100 parts of G-grade cement, 75 parts of fresh water, 22 parts of lightening agent, 0.5 part of G403 oil well cement toughening agent, stable 10 parts, G33S oil well cement fluid loss reducer 2.5 parts, GH-9 oil well cement retarder 1.5 parts, G401 oil well cement expansion agent 2.5 parts, USZ oil well cement drag reducer 0.3 parts, XP-1 defoamer 0.2 parts .

[0032] The preparation method of the anti-gas channeling cement slurry system suitable for shale gas well cementing is the same as that in Example 1.

Embodiment 3

[0034] An anti-gas channeling cement slurry system suitable for shale gas cementing, including the following raw materials in parts by weight: 100 parts of G-grade cement, 64 parts of fresh water, 15 parts of lightening agent, 0.5 part of G403 oil well cement toughening agent, stable 8 parts, G33S oil well cement fluid loss reducer 2.5 parts, GH-9 oil well cement retarder 1.4 parts, G401 oil well cement expansion agent 2.5 parts, USZ oil well cement drag reducer 0.3 parts, XP-1 defoamer 0.2 parts .

[0035] The preparation method of the anti-gas channeling cement slurry system suitable for shale gas well cementing is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com