Mosquito-repellent plastic material and preparation method thereof

A plastic material and mosquito repellent technology, applied in botany equipment and methods, animal repellents, biocides, etc., can solve the problem of easy dissemination of mosquito repellent composition, unsustainable mosquito repellent effect, inconspicuous mosquito repellent effect, etc. problem, achieve uniform mosquito repellent effect, stimulate human metabolism, and improve mosquito repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

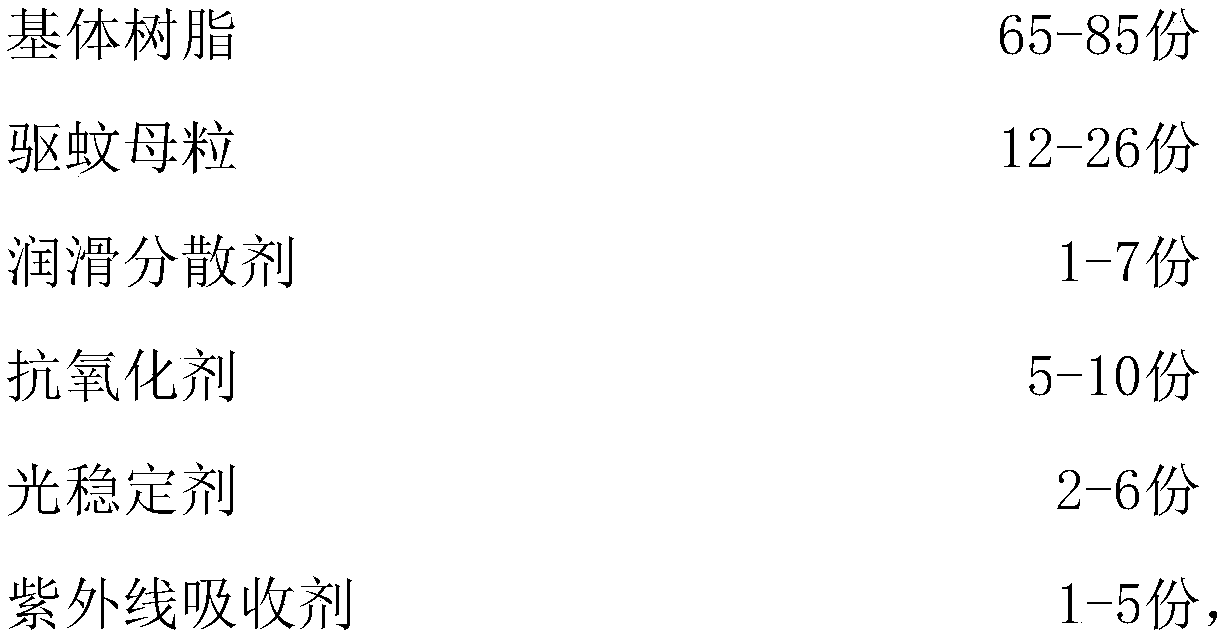

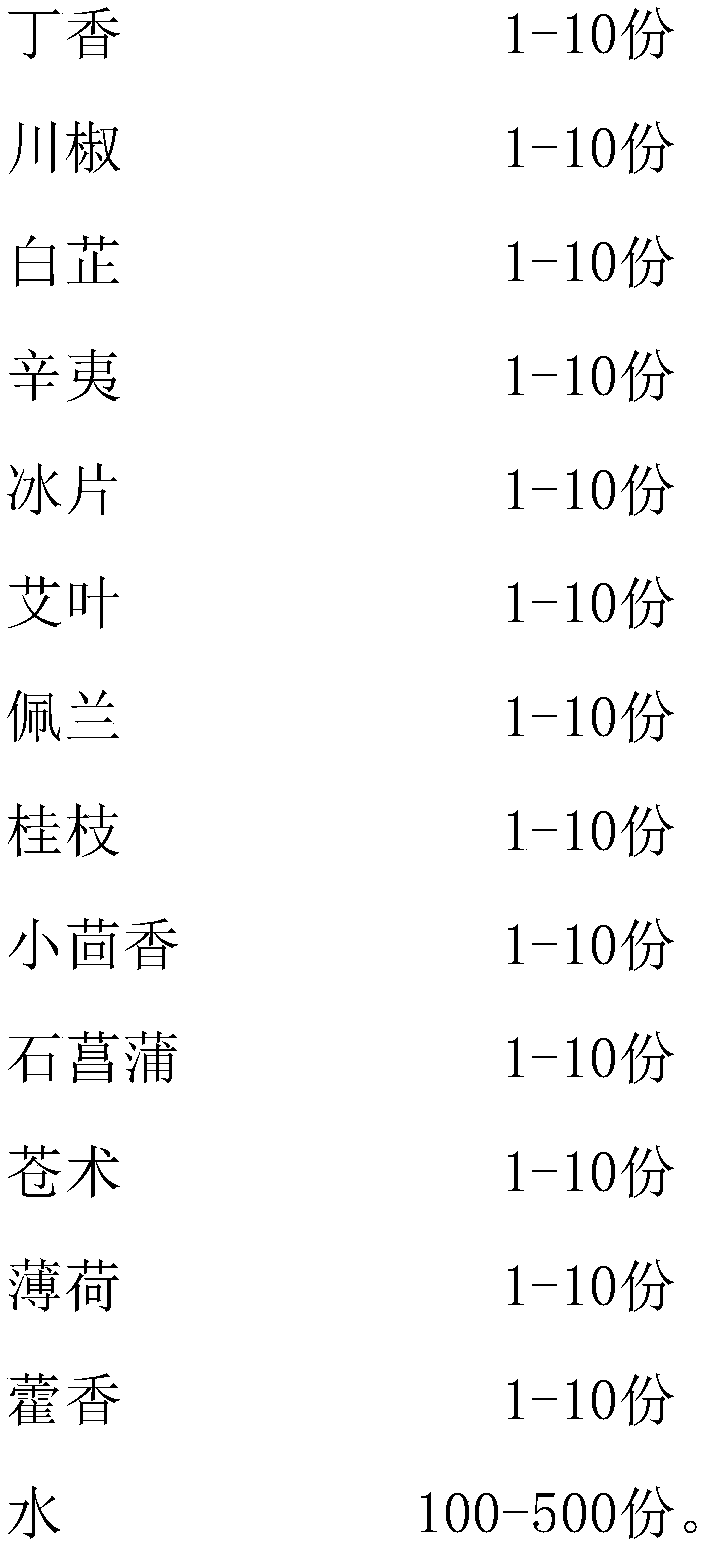

[0038] A mosquito repellent plastic material, comprising the following raw materials in parts by weight:

[0039]

[0040] Wherein, the mosquito repellent masterbatch is prepared by the following method:

[0041] A. Mix 1-allyl-3-methylimidazolium chloride and 1,3-dimethyl-2-imidazolidinone in a ratio of 2:1 by weight to form an ionic solvent, and heat up the ionic solvent As for 95°C, then gradually add microcrystalline cellulose to the ionic solvent during stirring, the amount of microcrystalline cellulose is 8wt% of the ionic solvent, until the ionic solvent is completely clear to obtain a clear solution of microcrystalline cellulose;

[0042] B. The nano-infrared material is sequentially added to the microcrystalline cellulose clarified solution obtained in step B, stirred and homogenized to obtain a suspension, wherein the amount of the nano-infrared material is 6wt% of the microcrystalline cellulose clarified solution;

[0043] C. Add the suspension obtained in step ...

Embodiment 2

[0058] A mosquito repellent plastic material, comprising the following raw materials in parts by weight:

[0059]

[0060] Wherein, the mosquito repellent masterbatch is prepared by the following method:

[0061] A. Mix 1-allyl-3-methylimidazolium chloride and 1,3-dimethyl-2-imidazolidinone in a weight ratio of 1:1 to form an ionic solvent, and heat up the ionic solvent As for 90°C, then gradually add microcrystalline cellulose to the ionic solvent during stirring, the amount of microcrystalline cellulose is 6wt% of the ionic solvent, until the ionic solvent is completely clear to obtain a clear solution of microcrystalline cellulose;

[0062] B. The nano-infrared material is sequentially added to the microcrystalline cellulose clarified solution obtained in step B, stirred and homogenized to obtain a suspension, wherein the amount of the nano-infrared material is 5wt% of the microcrystalline cellulose clarified solution;

[0063] C. Add the suspension obtained in step B t...

Embodiment 3

[0079] A mosquito repellent plastic material, comprising the following raw materials in parts by weight:

[0080]

[0081] Wherein, the mosquito repellent masterbatch is prepared by the following method:

[0082] A. Mix 1-allyl-3-methylimidazolium chloride and 1,3-dimethyl-2-imidazolidinone in a ratio of 3:1 by weight to form an ionic solvent, and heat up the ionic solvent As for 100°C, then gradually add microcrystalline cellulose to the ionic solvent during stirring, the amount of microcrystalline cellulose is 10wt% of the ionic solvent, until the ionic solvent is completely clear to obtain a clear solution of microcrystalline cellulose;

[0083] B. The nano-infrared material is sequentially added to the microcrystalline cellulose clarified solution obtained in step B, stirred and homogenized to obtain a suspension, wherein the amount of the nano-infrared material is 7wt% of the microcrystalline cellulose clarified solution;

[0084] C. Add the suspension obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com