A preparation method of long-chain nylon composite material for 3D printing

A long-chain nylon and composite material technology, applied in the direction of additive processing, etc., can solve problems such as poor strength, low heat resistance temperature, and large shrinkage rate, and achieve high thermal deformation temperature, lower melt viscosity, and low thermal deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

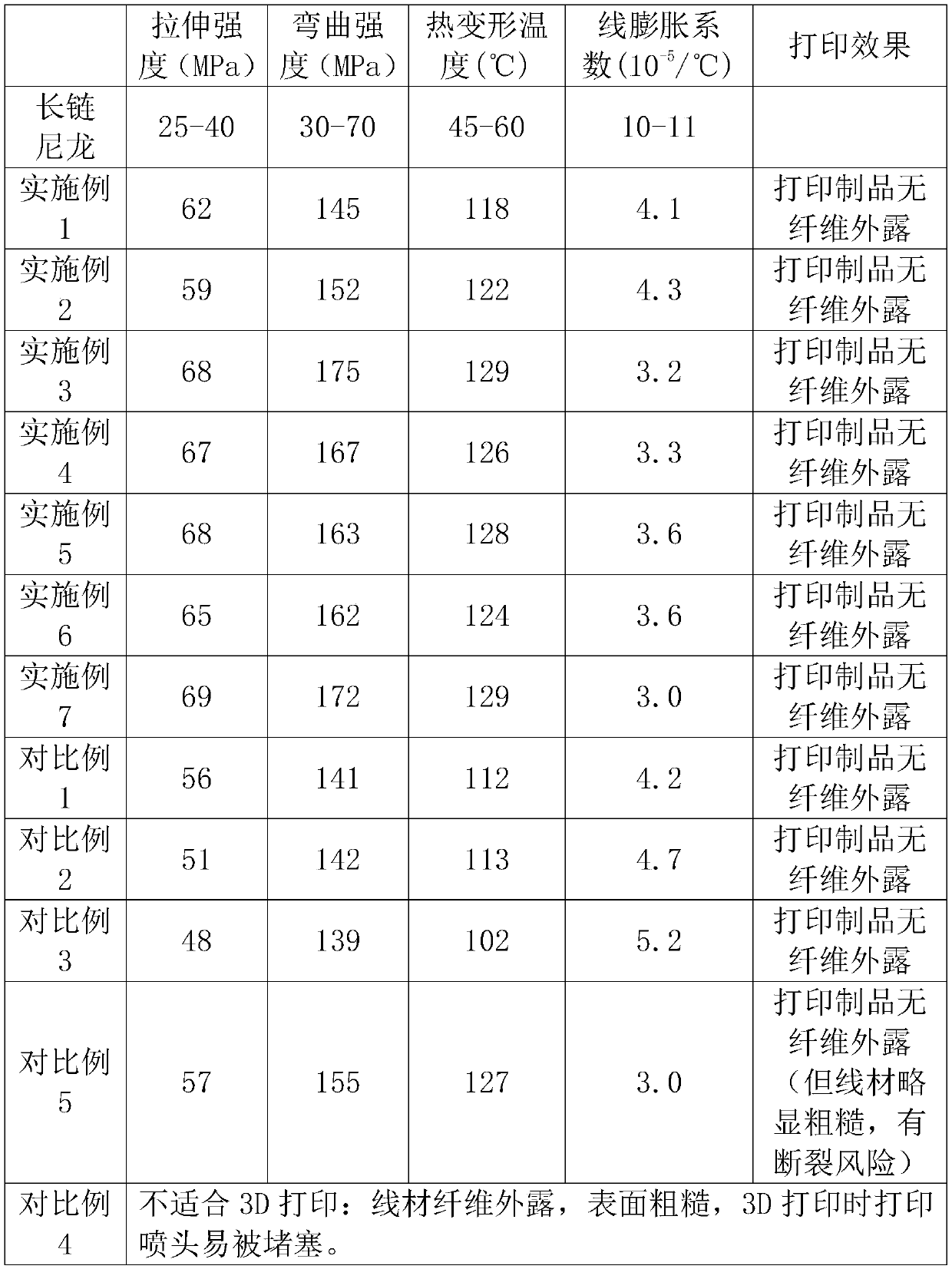

Examples

Embodiment 1

[0042] This embodiment provides a method for preparing a long-chain nylon composite material for 3D printing, comprising the following steps:

[0043] Prepare the following raw materials in parts by weight: 100 parts of long-chain nylon, 5 parts of kevlar chopped fiber, 10 parts of wollastonite, 0.2 part of coupling agent, 3 parts of toughening agent, 0.5 part of hyperbranched resin, and 0.2 part of antioxidant; The kevlar chopped fiber has a length of 2 mm and a diameter of 12 μm; the aspect ratio of the wollastonite needle-like fiber is above 15; the long-chain nylon is PA11; the coupling agent is a silane coupling agent, and the structural formula is NH 2 (CH 2 ) 3 Si(OC 2 h 5 ) 3 ; The toughening agent is maleic anhydride grafted EPDM rubber; the hyperbranched resin is Hyper C100; the antioxidant is antioxidant 1076;

[0044] Prepare the coupling agent solution with ethanol, and adjust its pH value to between 4-5.5;

[0045] Spray the wollastonite into the atomized ...

Embodiment 2

[0050] This embodiment provides a method for preparing a long-chain nylon composite material for 3D printing, comprising the following steps:

[0051] Prepare the following raw materials in parts by weight: 100 parts of long-chain nylon, 7 parts of kevlar chopped fiber, 5 parts of wollastonite, 0.1 part of coupling agent, 7 parts of toughening agent, 0.7 part of hyperbranched resin, and 0.4 part of antioxidant; The kevlar chopped fiber has a length of 3 mm and a diameter of 10 μm; the aspect ratio of the wollastonite needle-like fiber is above 15; the long-chain nylon is PA1012; the coupling agent is a silane coupling agent, structural formula for NH 2 (CH 2 ) 3 Si(OCH 3 ) 3 ; The toughening agent is maleic anhydride grafted EPDM rubber; the hyperbranched resin is Hyper H402; the antioxidant is antioxidant 330;

[0052] Prepare the coupling agent solution with water, and adjust its pH value to between 4-5.5;

[0053] Spray the wollastonite into the atomized coupling agen...

Embodiment 3

[0058] This embodiment provides a method for preparing a long-chain nylon composite material for 3D printing, comprising the following steps:

[0059] Prepare the following raw materials in parts by weight: 100 parts of long-chain nylon, 8 parts of kevlar chopped fiber, 15 parts of wollastonite, 0.3 part of coupling agent, 3 parts of toughening agent, 0.7 part of hyperbranched resin, and 1 part of antioxidant; The kevlar chopped fiber has a length of 2.5 mm and a diameter of 12 μm; the aspect ratio of the wollastonite needle-like fiber is above 15; the long-chain nylon is PA1212; the coupling agent is a silane coupling agent, the structural formula for The toughening agent is maleic anhydride grafted EPDM rubber; the hyperbranched resin is Hyper H401; the antioxidant is antioxidant 1790;

[0060] Prepare the coupling agent solution with ethanol, and adjust its pH value to between 4-5.5;

[0061] Spray the wollastonite into the atomized coupling agent solution while stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com