Waterborne two-component varnish and preparation method thereof

A water-based two-component, varnish technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as unbalanced acid and alkali resistance, easy water loss, increased steps, etc., to improve hot-stick defects, cold and brittle, Good moisturizing performance and the effect of improving film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of waterborne two-component varnish

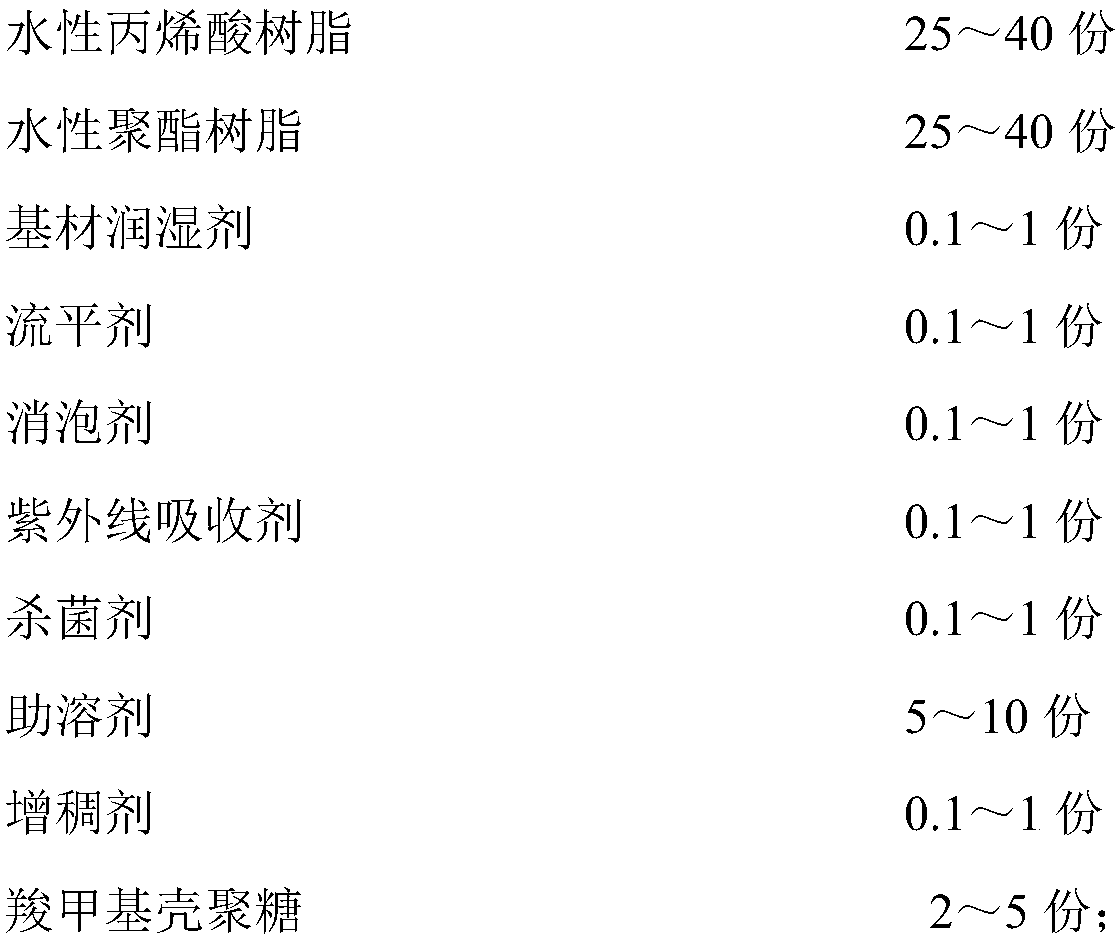

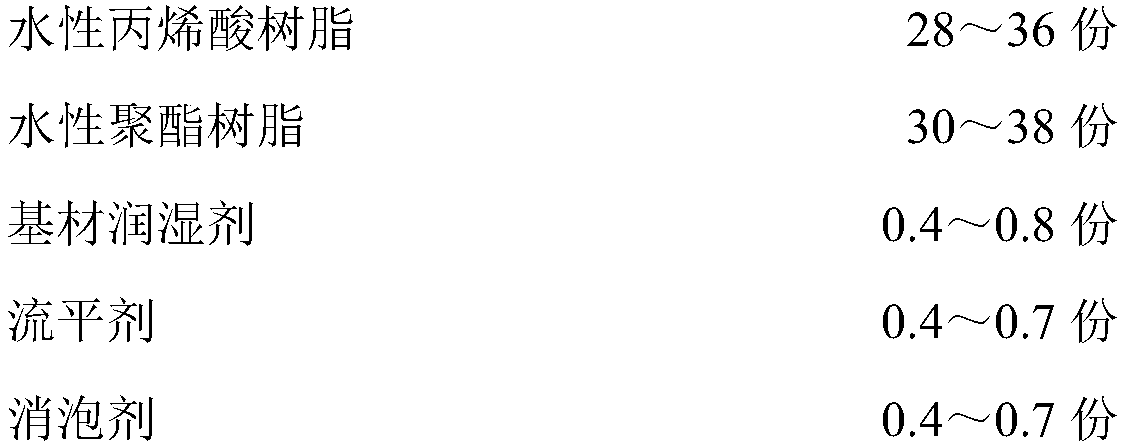

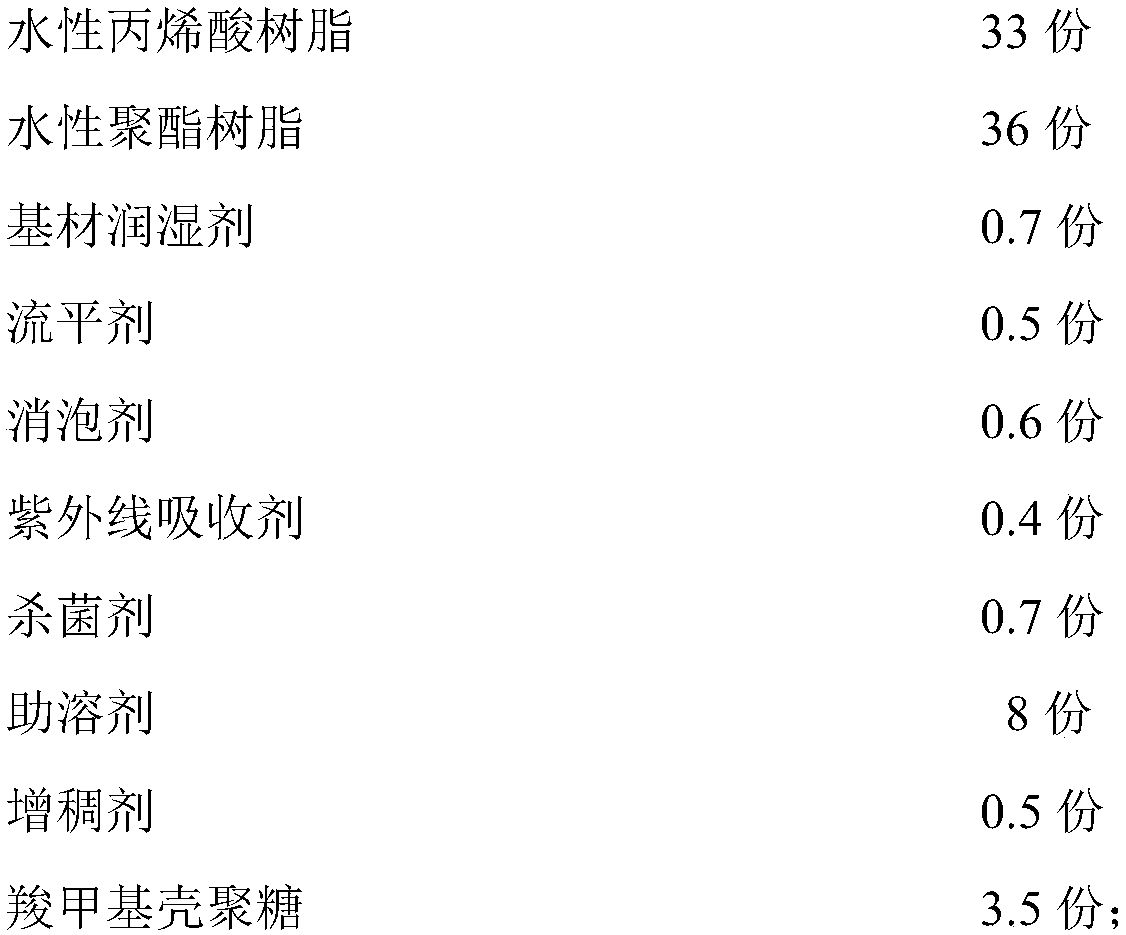

[0051] The formula of waterborne two-component varnish is as shown in table 1, and its preparation process is as follows:

[0052] (1) Put the formulated amount of water-based acrylic resin and water-based polyester resin into the container in sequence and mix them evenly, then slowly add carboxymethyl chitosan, substrate wetting agent, leveling agent, defoamer, and ultraviolet absorber , bactericide and co-solvent, then add thickener, stir evenly, filter and discharge to obtain component A;

[0053] (2) Add a formula amount to the container to mix the isocyanate curing agent, adhesion promoter and cosolvent, and filter the discharge to obtain component B;

[0054] (3) Mix according to the mixing ratio of A and B as 3:1 to obtain a water-based two-component varnish.

[0055] Table 1 Waterborne two-component varnishes of different formulations

[0056]

[0057] Water-based two-component varnish performance testing d...

Embodiment 2

[0066] Table 4 shows the feeding formula of Example 2 when the types of substances in the formula are kept unchanged, and the content of each substance is changed. The water-based two-component varnish is prepared according to the process of Example 1.

[0067] The properties of the obtained water-based two-component varnishes prepared by formulas 6 to 9 are shown in Table 5. Compared with the properties of Table 2, it can be seen that when the weight parts of the various substances of the A and B components exceed the range disclosed in the table of Example 1, The performance of the obtained water-based two-component varnish is drastically reduced in all aspects.

[0068] Table 4 Waterborne two-component varnishes of different formulations

[0069]

[0070] Water-based two-component varnish performance testing data of different formulations in table 5

[0071]

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com