Structural silicone adhesive with low modulus and high volume resistivity

A high volume resistivity, structural adhesive technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of no photovoltaic module silicone structural adhesive, and reduce free ammonia ions. , The effect of reducing dosage and high volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

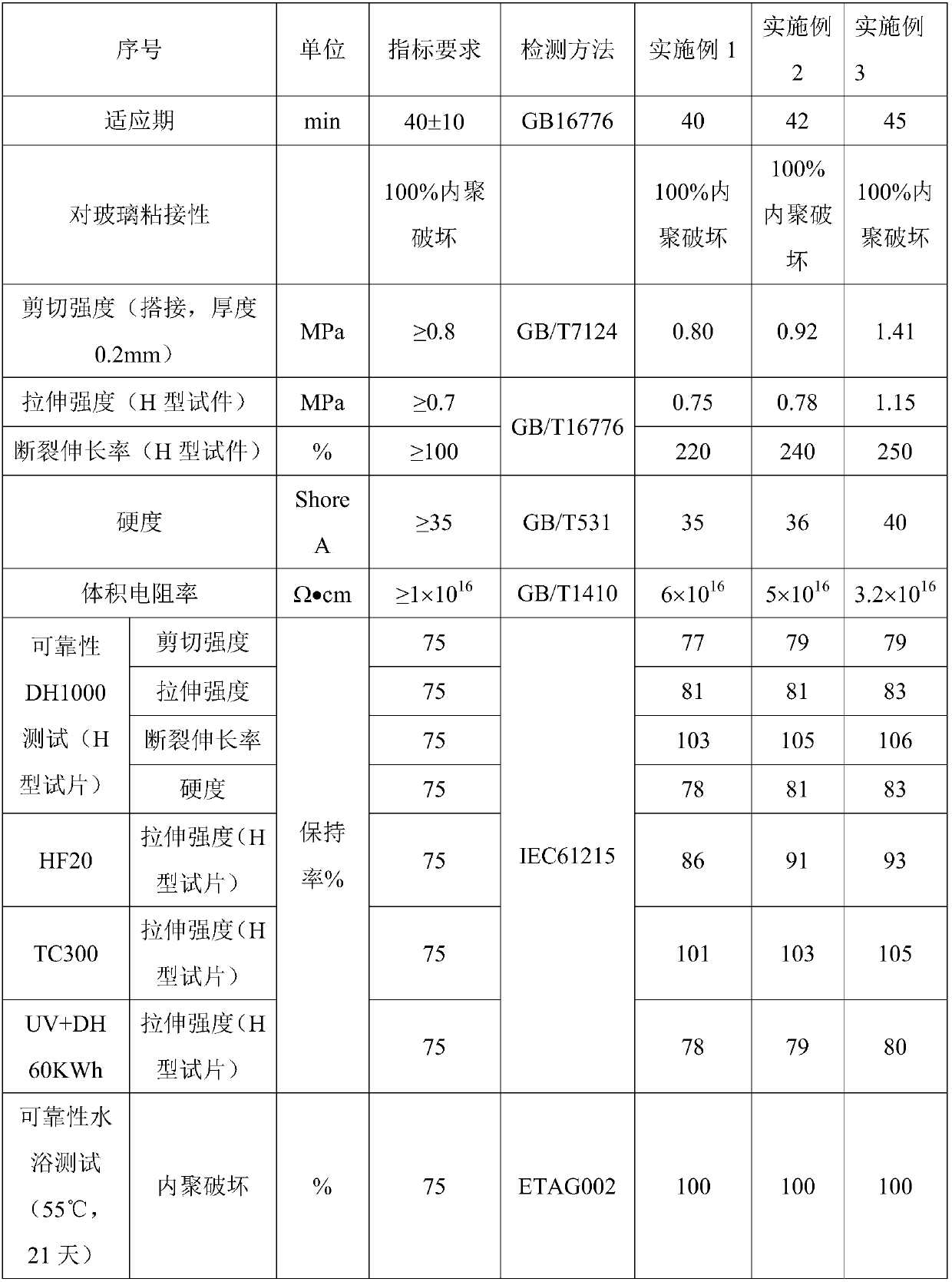

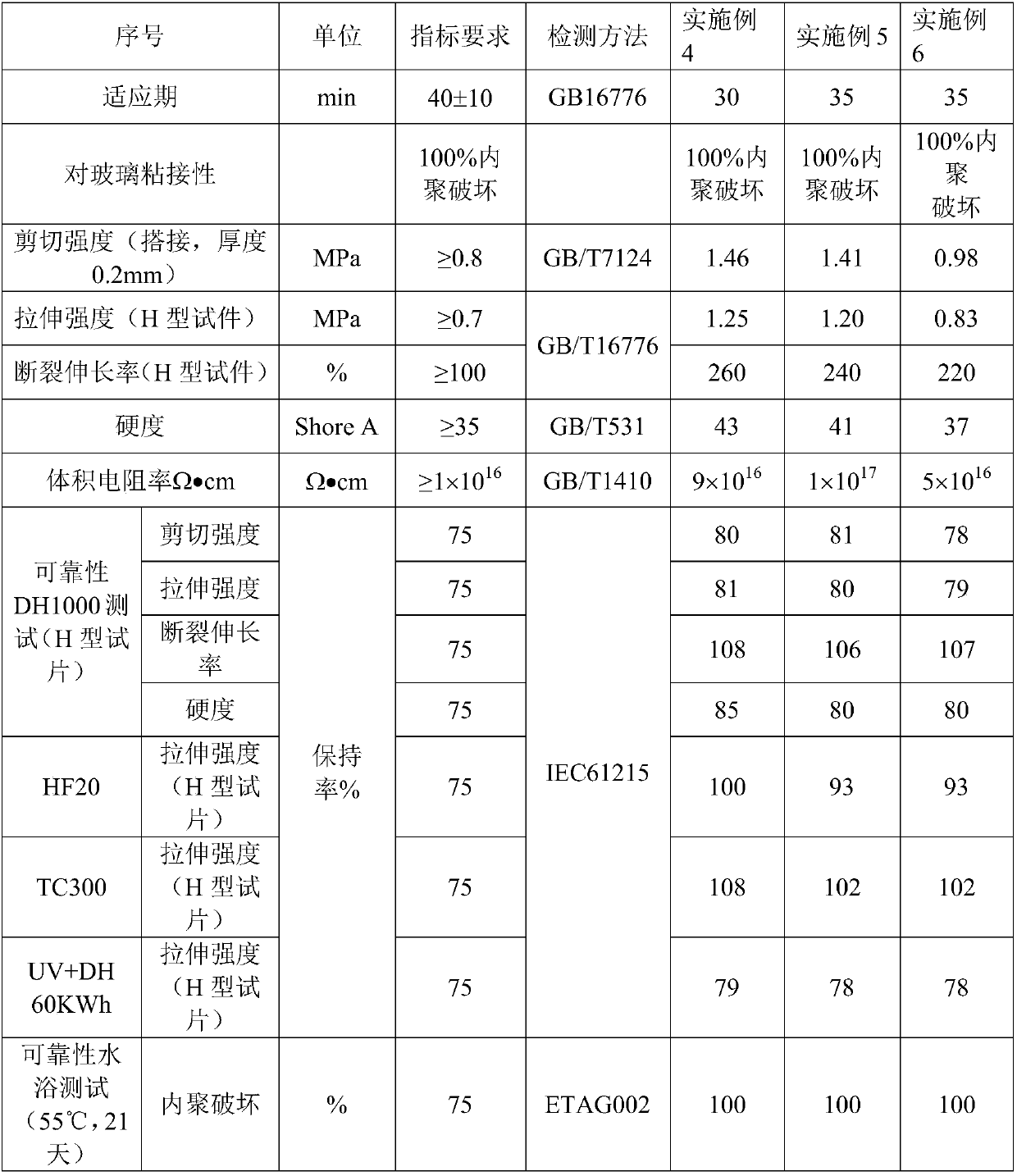

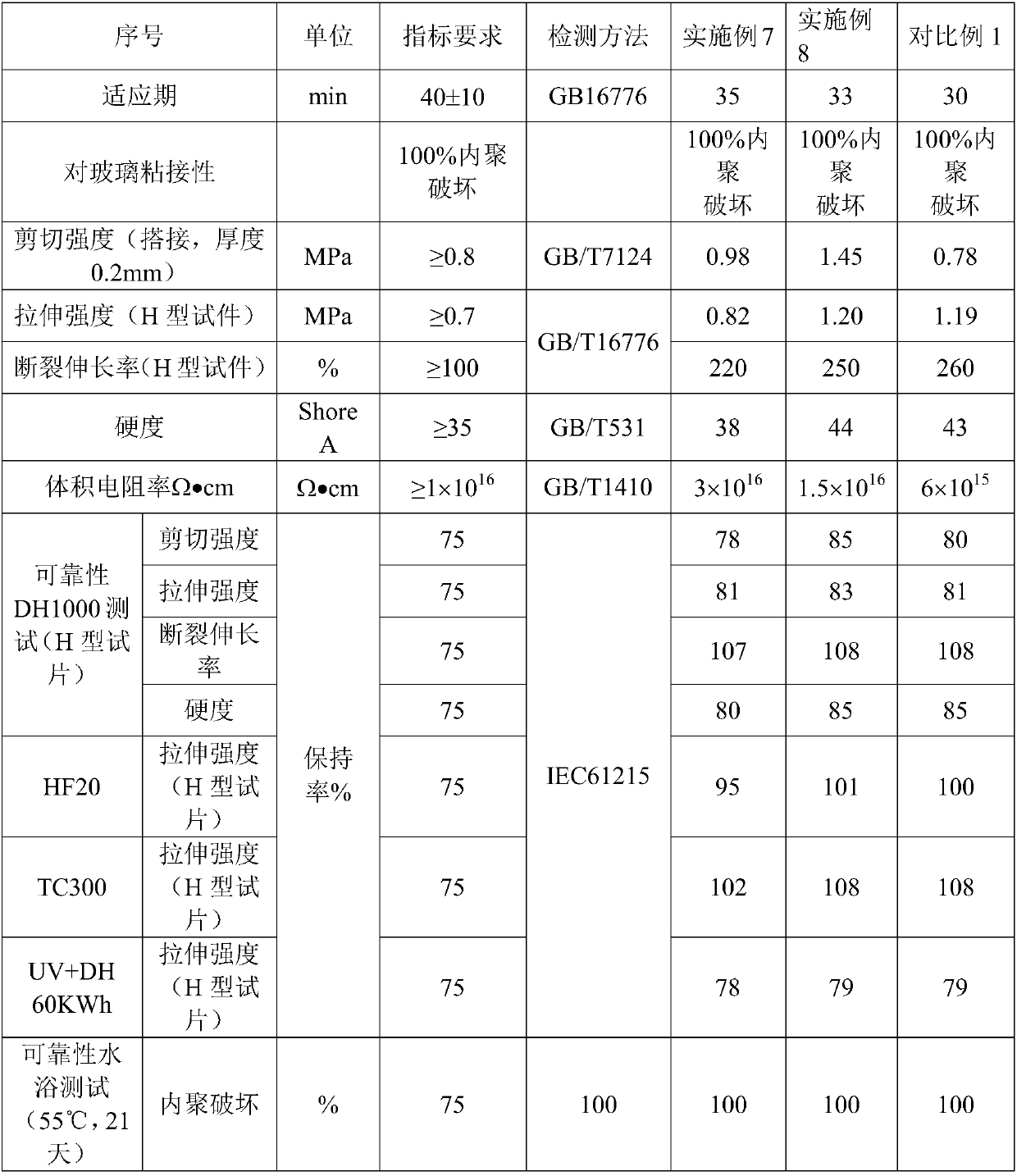

Examples

Embodiment 1

[0028]Preparation of composite coupling agent: 1mol of aminopropyltrimethoxysilane, 1mol of aminopropyltriethoxysilane, 1mol of bis(trimethoxysilylpropyl)amine, 2-(3,4-epoxy ring Hexyl)ethyltrimethoxysilane 2mol, 3-(2,3-epoxypropoxy)propyltrimethoxysilane 4mol, according to the moles of silane coupling agent with amino group and silane coupling agent with epoxy group After mixing evenly at a ratio of 1:2, seal it, heat it in an oven at 70°C for 3 hours, and then cool it to room temperature to prepare a composite coupling agent for future use.

[0029] Preparation of component A: 80 parts by weight of filler, the mass ratio of calcium carbonate to fumed silica is 15:1, wherein the particle size of calcium carbonate is 15nm, and the treating agent of fumed silica is octamethylcyclotetrasiloxane, The specific surface area is 150m 2 / g. 50 parts by weight of 20,000 cs-terminated hydroxyl polydimethylsiloxane (abbreviated as 107 glue, hereinafter referred to as abbreviation), 50 ...

Embodiment 2

[0033] Preparation of composite coupling agent: 1 mol of aminopropyltrimethoxysilane, 1mol of aminopropyltriethoxysilane, 1mol of bis(trimethoxysilylpropyl)amine, 1mol of triethoxysilylpropyl Amine 1mol, 3-(2,3-epoxypropoxy)propyltriethoxysilane 4mol, 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane 8mol, according to the amino group The silane coupling agent and the silane coupling agent with epoxy group were mixed evenly in a molar ratio of 1:3, sealed, heated in an oven at 80°C for 2.5 hours, and then cooled to room temperature to prepare a composite coupling agent for use.

[0034] Preparation of component A: 90 parts by weight of filler, the mass ratio of calcium carbonate to fumed silica is 14:1, wherein the particle size of calcium carbonate is 40nm, and the treating agent of fumed silica is hexamethyldisilazane, the ratio Surface area is 150m 2 / g. Add 40 parts by weight of 20,000 cs 107 glue, 60 parts by weight of 80,000 cs 107 glue, 20 parts by weight of 80 cs termi...

Embodiment 3

[0038] Preparation of composite coupling agent: 1mol of aminopropyltrimethoxysilane, 2mol of aminoethylaminopropylpropyltrimethoxysilane, 1.5mol of triethoxysilylethane, bis(trimethoxysilyl Propyl)amine 3mol and 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane 10mol, 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane 5mol, according to the molar ratio of silane coupling agent with amino group and silane coupling agent with epoxy group 1:2, after mixing evenly, airtight, heat in an oven at 90°C for 2h, then cool to room temperature, and prepare a composite coupling agent for later use .

[0039] Preparation of component A: 70 parts by weight of filler, the mass ratio of calcium carbonate to fumed silica is 13:1, wherein the particle size of calcium carbonate is 20nm, the treating agent of fumed silica is dimethyldichlorosilane, and the specific surface area 180m 2 / g. Add 30 parts by weight of 20,000 cs 107 glue, 70 parts by weight of 80,000 cs 107 glue, 5 parts by weight of 70 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com