Cleaning solution for optical materials

A technology for optical materials and cleaning fluids, applied in the direction of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve the problems of unsuitability for large-scale use and complicated steps, achieve low cost, reduce contact probability, increase The effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

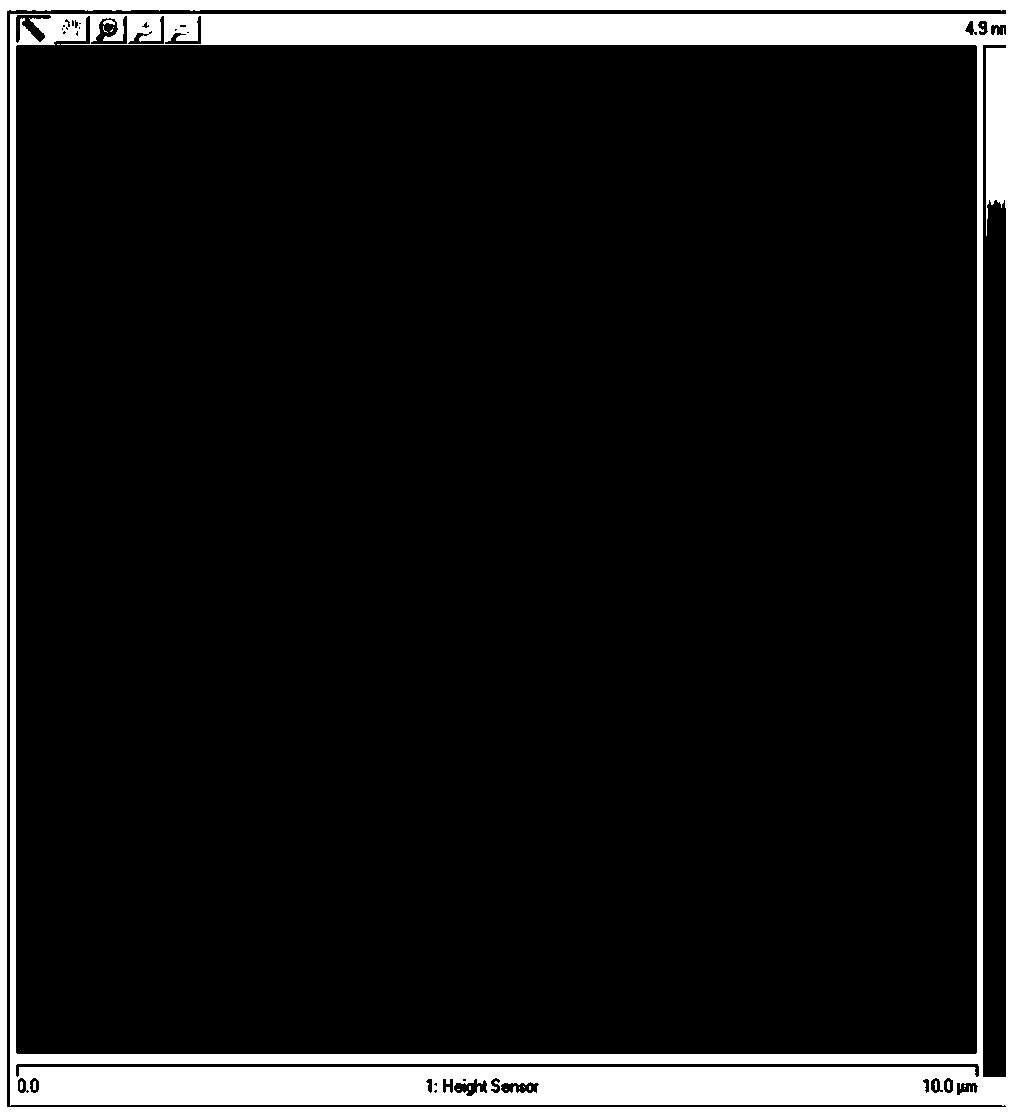

[0035] Preparation of cleaning solution: under constant stirring, add phosphate ester series surfactants to deionized water until they are completely dissolved, then add hydrogen bond breakers, complexing agents, alcohols and salts in sequence, and finally add pH regulators , the pH of the cleaning solution=8.6. The content of each component is respectively: anionic surfactant (MOA-3P) 10wt%, hydrogen bond breaker (urea) 0.1wt%, complexing agent (NTA) 5wt%, alcohols (ethanol) 10wt%, pH adjustment Wetting agent (hydrochloric acid) 0.1wt%, salt (potassium nitrate) 0.5wt%. The atomic force microscope detects the surface residue effect after cleaning, and there are no surface particles and other residues.

Embodiment 2

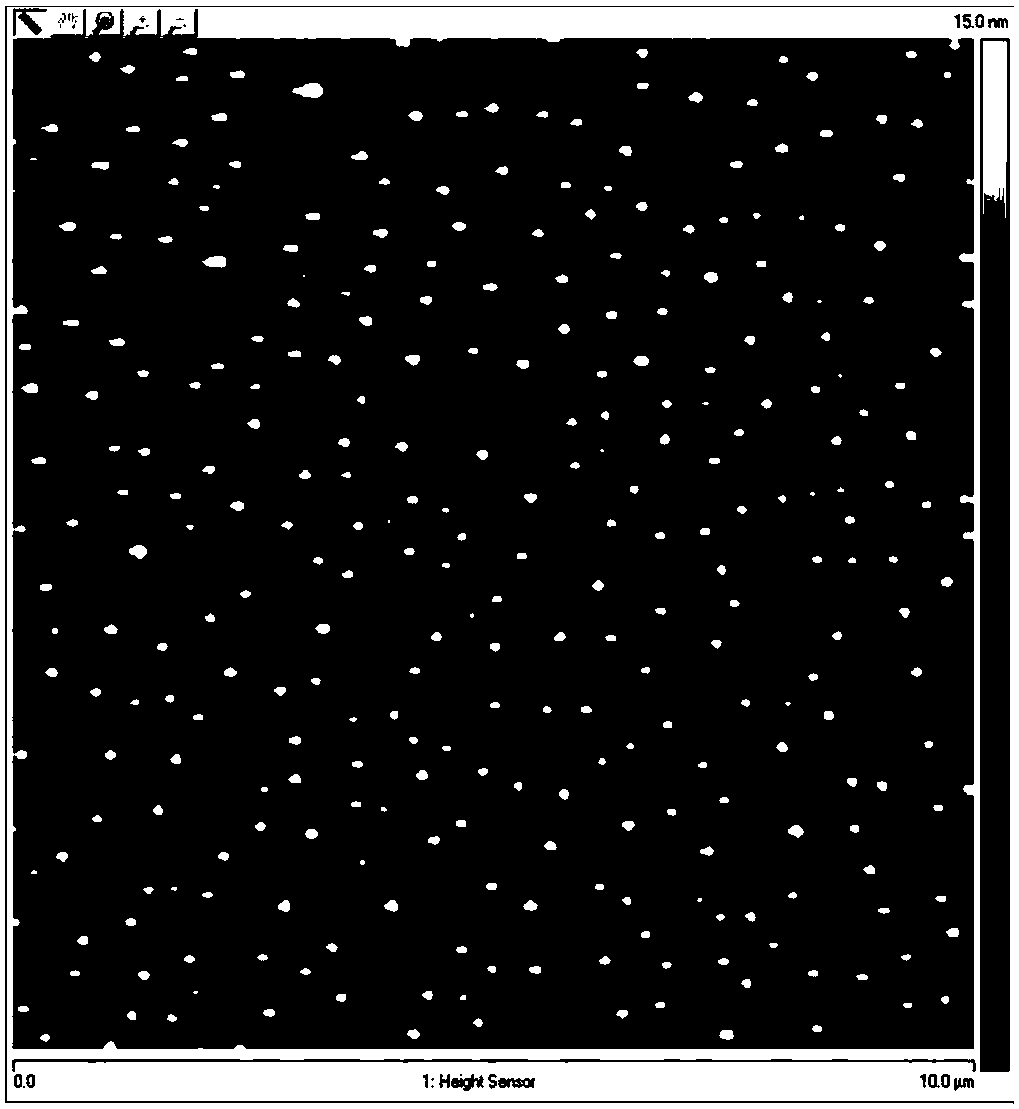

[0037] Preparation of cleaning solution: under constant stirring, add phosphate ester series surfactants to deionized water until they are completely dissolved, then add hydrogen bond breakers, complexing agents, alcohols and salts in sequence, and finally add pH regulators , the pH of the cleaning solution=5.2. Make each component content be respectively: anionic surfactant (TXP-10) 4wt%, hydrogen bond breaking agent (formamide) 0.5wt%, complexing agent (EDTA) 1wt%, alcohols (ethylene glycol) 5wt% , PH regulator wetting agent (acetic acid) 1wt%, salt (sodium phosphate) 0.1wt%. The atomic force microscope detects the surface residue effect after cleaning, with a small amount of surface particles and no other residues.

Embodiment 3

[0039] Preparation of cleaning solution: under constant stirring, add phosphate ester series surfactants to deionized water until they are completely dissolved, then add hydrogen bond breakers, complexing agents, alcohols and salts in sequence, and finally add pH regulators , the pH of the cleaning solution=9.1. Make each component content be respectively: anionic surfactant (NP-10PK-80) 5wt%, hydrogen bond breaker (guanidine hydrochloride) 0.3wt%, complexing agent (EDTA) 2wt%, alcohols (glycerol) 7wt%, PH regulator wetting agent (potassium hydroxide) 2wt%, salt (sodium sulfate) 0.6wt%. The atomic force microscope detects the surface residue effect after cleaning, and there are no surface particles and other residues.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com