Biodegradable mulching film with multi-layer structure

A biodegradable, multi-layer structure technology, applied in plant protection, plant protection cover, botanical equipment and methods, etc., can solve the problems of poor performance such as anti-aging, anti-ultraviolet and heat resistance, short service life, affecting the growth environment of crops, etc. problem, to achieve good moisturizing effect, satisfactory service life, and excellent anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

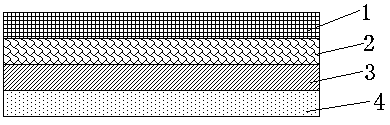

[0018] Such as figure 1 As shown, the mulch film from top to bottom is an anti-aging layer 1, a water-proof layer 2, an insulating layer 3, and a water-retaining layer 4, wherein the anti-aging layer contains the following components: 100 parts of terephthalate copolymer , 10 parts of polylactic acid, 30 parts of nano-calcium carbonate, 0.2 part of erucamide, 0.5 part of ultraviolet absorber, and the ultraviolet absorber is UV-0;

[0019] The waterproof layer includes the following components: 100 parts of hydroxypropylated starch, 30 parts of polylactic acid, and 2 parts of polyethylene glycol;

[0020] The insulation layer contains the following components: 100 parts of polyvinyl alcohol, 10 parts of polylactic acid, 20 parts of polyhydroxyalkanoate, 3 parts of superfine talcum powder, 0.2 part of erucamide, and 0.5 part of citric acid;

[0021] The water-retaining layer comprises the following components: 100 parts of polyacrylic resin, 20 parts of polylactic acid, 5 parts...

Embodiment 2

[0023] Such as figure 1 As shown, the mulch film from top to bottom is an anti-aging layer 1, a water-proof layer 2, an insulating layer 3, and a water-retaining layer 4, wherein the anti-aging layer contains the following components: 100 parts of terephthalate copolymer , 20 parts of polylactic acid, 37 parts of nano-calcium carbonate, 0.3 part of erucamide, 1 part of ultraviolet absorber, the ultraviolet absorber is UV-9;

[0024] The water barrier layer includes the following components: 100 parts of hydroxypropylated starch, 75 parts of polylactic acid, and 4 parts of acetyl tri-n-butyl citrate;

[0025] The insulation layer contains the following components: 100 parts of polyvinyl alcohol, 20 parts of polylactic acid, 35 parts of polyhydroxyalkanoate, 7 parts of superfine talcum powder, 0.3 part of erucamide, and 0.7 part of citric acid;

[0026] The water-retaining layer comprises the following components: 100 parts of polyacrylic resin, 30 parts of polylactic acid, 7 p...

Embodiment 3

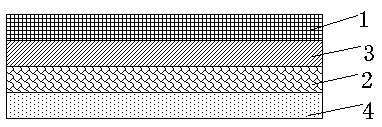

[0028] Such as figure 2 As shown, the mulch film is an anti-aging layer 1, an insulating layer 3, a water-proof layer 2, and a water-retaining layer 4 from top to bottom, wherein the anti-aging layer includes the following components: 100 parts of terephthalate copolymer , 30 parts of polylactic acid, 45 parts of nano-calcium carbonate, 0.5 parts of erucamide, 2 parts of ultraviolet absorber, the ultraviolet absorber is UV-531;

[0029] The waterproof layer includes the following components: 100 parts of hydroxypropylated starch, 100 parts of polylactic acid, and 6 parts of polyethylene glycol;

[0030] The insulation layer contains the following components: 100 parts of polyvinyl alcohol, 30 parts of polylactic acid, 50 parts of polyhydroxyalkanoate, 10 parts of superfine talcum powder, 0.5 parts of erucamide, and 1 part of citric acid;

[0031] The water-retaining layer comprises the following components: 100 parts of polyacrylic resin, 40 parts of polylactic acid, 10 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com