The preparation method of 2-methyl-1-ethynyl-2-penten-1-ol

A technology of ethynyl and methyl, which is applied in the field of preparation of 2-methyl-1-ethynyl-2-penten-1-ol, which can solve the problems of large amount of wastewater treatment, large environmental pollution, and large production odor , to achieve the effect of high product yield, lower production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

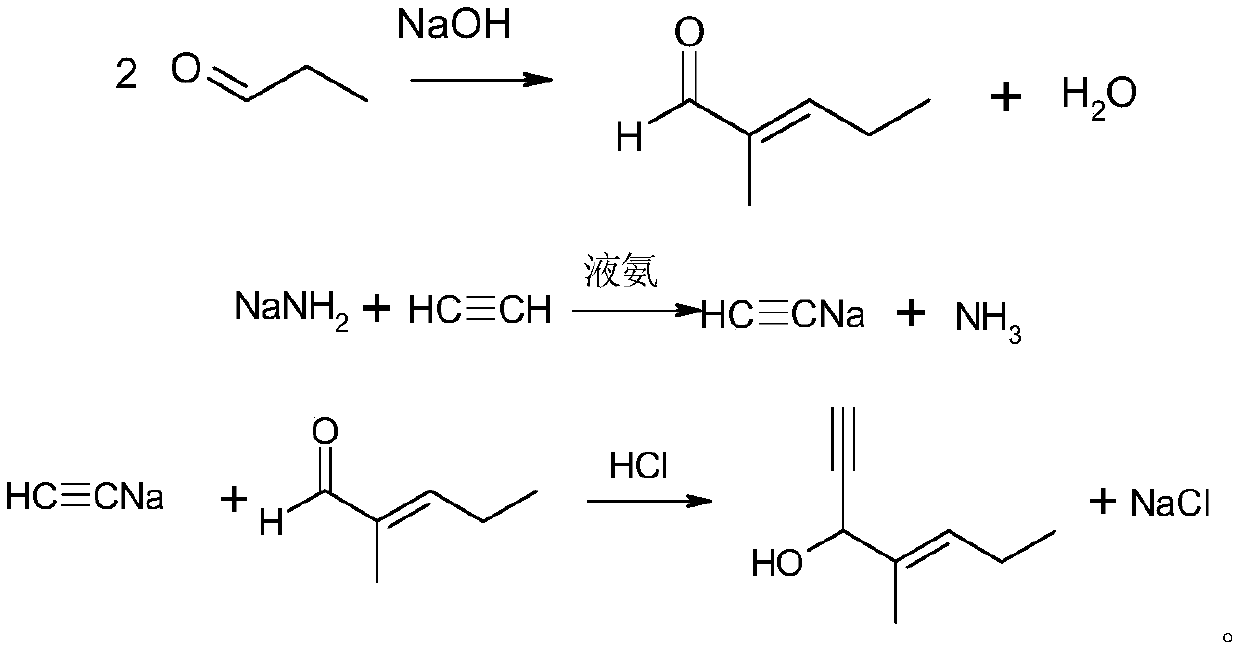

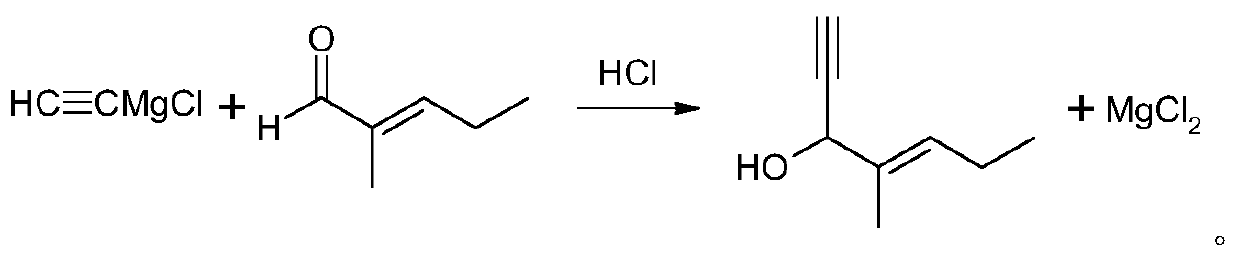

Method used

Image

Examples

Embodiment 1

[0035] 1, a kind of preparation method of 2-methyl-1-ethynyl-2-penten-1-alcohol, comprises the following steps:

[0036] (1) Put 48kg of magnesium chips and 1440kg of tetrahydrofuran into the reaction kettle, add 4.8kg of methylmagnesium chloride and stir at 50-60°C for Grignard initiation; Add methyl chloride at a constant speed to the system until the pressure of the system rises and the magnesium chips react completely to generate methylmagnesium chloride;

[0037] (2) Cool the methylmagnesium chloride generated in step (1) to -20—-10°C, add 0.048kg of tributylamine, and add 57.2kg of acetylene to the system at a uniform speed within 10 hours at this temperature to react, add Sampling in the process of acetylene is carried out gas chromatographic analysis, and the reaction is completed when the quality of methylmagnesium chloride in the system is less than or equal to 0.5%.

[0038] (3) Add 156.8kg of 2-methyl-2-pentenal dropwise to the system after the reaction in step (2...

Embodiment 2

[0040] 1, a kind of preparation method of 2-methyl-1-ethynyl-2-penten-1-alcohol, comprises the following steps:

[0041] (1) Put 48kg of magnesium chips and 960kg of tetrahydrofuran into the reaction kettle, add 4.8kg of methylmagnesium chloride and stir at 50-60°C for Grignard initiation; when the temperature of the system rises, the initiation begins. Add methyl chloride at a constant speed to the system until the pressure of the system rises and the magnesium chips react completely to generate methylmagnesium chloride;

[0042](2) Cool down the methylmagnesium chloride generated in step (1) to -20—-10°C, add 0.096kg of triethylamine, then add 62.4kg of acetylene to the system at a uniform speed within 10 hours at this temperature to react, add Sampling in the process of acetylene is carried out gas chromatographic analysis, and the reaction is completed when the quality of methylmagnesium chloride in the system is less than or equal to 0.5%.

[0043] (3) Add 156.8kg of 2-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com