Preparation method of heptanuclear manganese-substituted silicon tungsten oxide catalyst and application thereof

A technology of manganese substitution and catalyst, which is applied in the field of preparation of heptanuclear manganese substitution silicotungsten oxygen cluster catalysts, can solve the problems of undiscovered patent documents and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

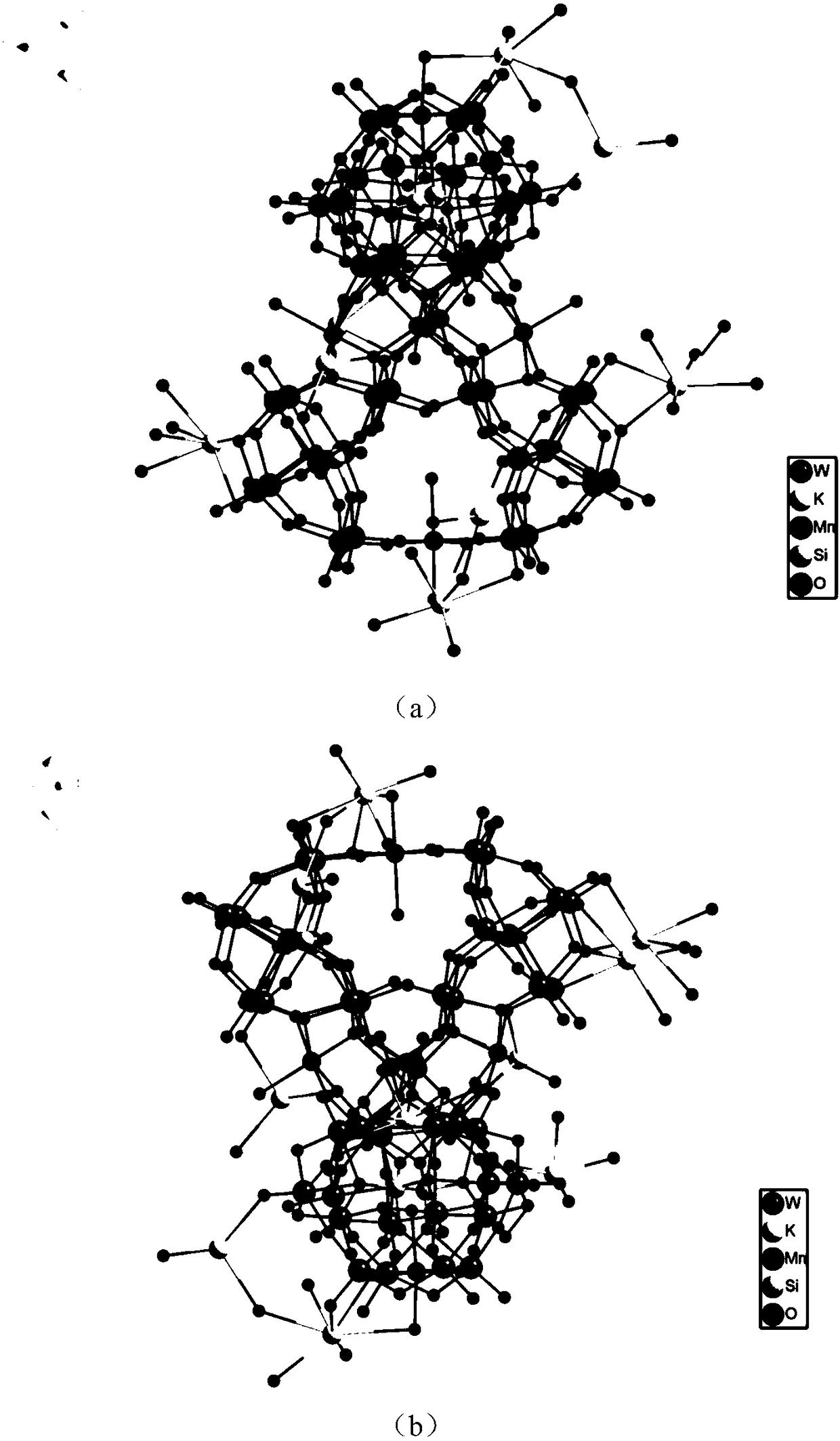

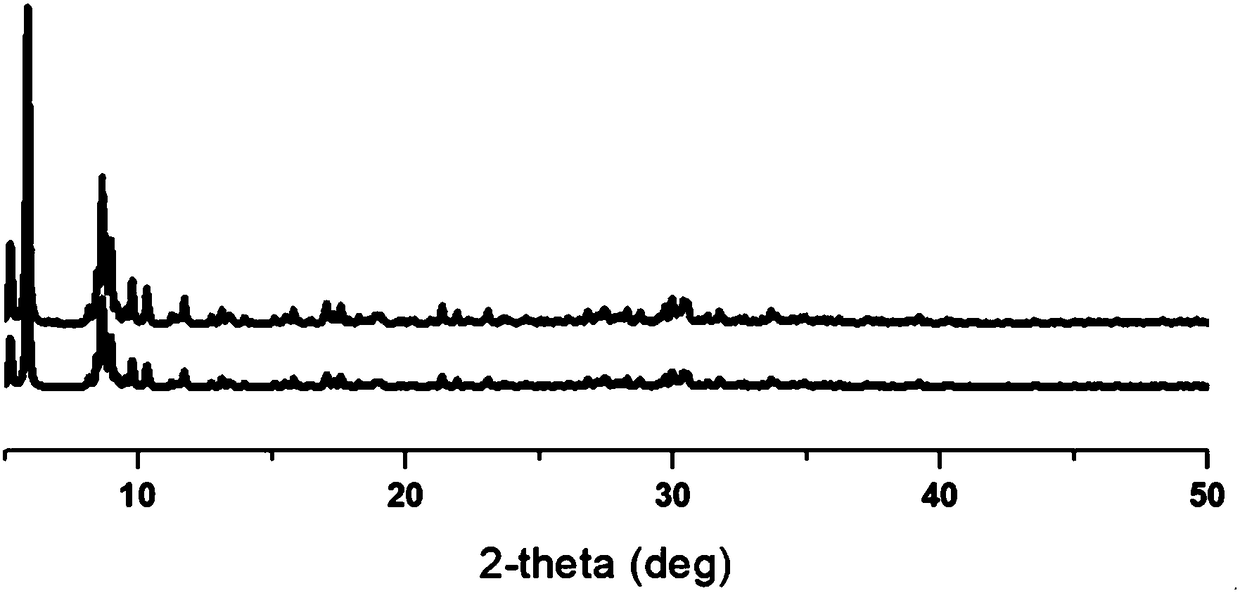

[0026] Example 1: Compound K 10 (H 2 O) 26 mn 7 (H 2 O) 9 Si 4 W 40 o 140 preparation of

[0027] Add sodium tungstate (0.5mmol), water (10 mL), manganese chloride (0.1mmol), sodium silicate (0.1mmol), potassium chloride (0.8mmol) in a clean reaction kettle The pH of the solution was adjusted to 4 with hydrochloric acid, stirred for 12 hours, and reacted at 150 degrees Celsius for 5 days. After the reaction was completed, it was cooled to room temperature and filtered to obtain black crystals. The yield is about 31%.

Embodiment 2

[0028] Example 2: Compound K 10 (H 2 O) 26 mn 7 (H 2 O) 9 Si 4 W 40 o 140 preparation of

[0029] Add sodium tungstate (0.6mmol), water (15 mL), manganese chloride (0.1mmol), sodium silicate (0.1mmol), potassium chloride (0.8mmol) in a clean reaction kettle The pH of the solution was adjusted to 4 with hydrochloric acid, stirred for 12 hours, and reacted at 150 degrees Celsius for 5 days. After the reaction was completed, it was cooled to room temperature and filtered to obtain black crystals. The yield is about 35%.

Embodiment 3

[0030] Example 3: Compound K 10 (H 2 O) 26 mn 7 (H 2 O) 9 Si 4 W 40 o 140 preparation of

[0031] Add sodium tungstate (0.7mmol), water (20 mL), manganese nitrate (0.5mmol), sodium silicate (0.1mmol), potassium chloride (0.8mmol) in a clean reaction kettle in turn The pH of the solution was adjusted to 6, stirred for 24 hours, and reacted at 160 degrees Celsius for 7 days. After the reaction was completed, it was cooled to room temperature and filtered to obtain black crystals. The yield is about 43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com