Light-emitting ceramic and light-emitting device

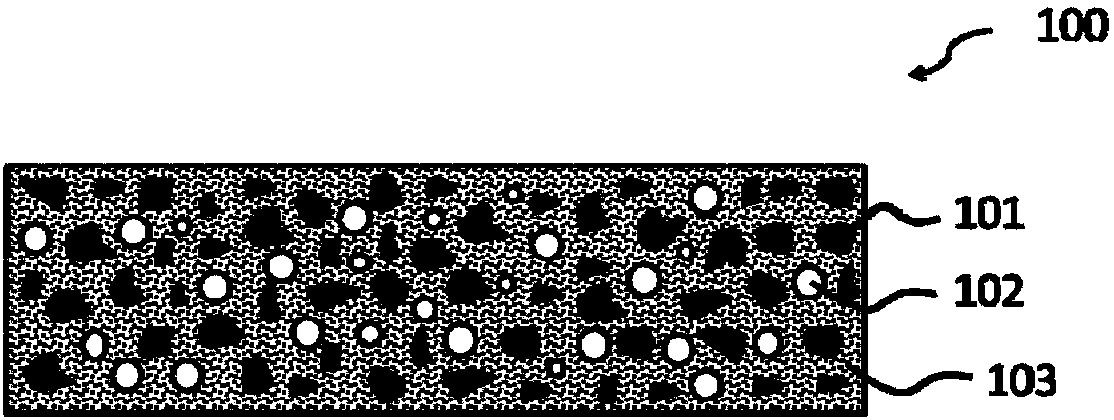

A technology of luminescent ceramics and luminescent centers, applied in luminescent materials, lasers, phonon exciters, etc., can solve the problems that luminescent ceramics cannot meet the use requirements, the blue light absorption efficiency is reduced, and the light conversion efficiency is low, and the consistency is easy to control. , Improve color rendering, uniform luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Traditional fluorescent solid packages, such as silica gel packaged phosphor powder, glass packaged luminescent glass, etc., are based on a transparent silicone continuum matrix or glass continuum matrix, and the phosphor powder is distributed in it. When the blue light is incident on the illuminant, the blue light can penetrate the transparent matrix and irradiate on the phosphor particles to perform photoluminescent energy conversion, and the heat generated is mainly transmitted through the continuous structure of the phosphor to the matrix. However, silica gel and glass have the disadvantages of low heat resistance and poor thermal conductivity. When used in a high-power laser light source, the silica gel system will age and become brittle due to high temperature, and even be burned; the heat resistance of the glass system is better. , but the thermal conductivity is low, and the sharp rise in temperature will still cause a significant drop in the efficiency of the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com