Soaping-free active digital ink-jet ink and preparation method thereof, and active ink-jet printing soaping-free printing and dyeing process used for fabrics

A digital inkjet ink and inkjet printing technology, applied in the field of printing and dyeing, can solve the problems that hinder the large-scale application of printing and dyeing enterprises, high ink prices, large waste water, etc., and achieve the effect of reducing the content of dyes, reducing ink costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of soap-free active digital ink-jet ink comprises the following steps:

[0036] 1) Take the filtered black P-type dye 8%, black KN-type dye 4%, surfactant AEO-30.02%, humectant 5% diethylene glycol, 1,2 propylene glycol 10%, fungicide isothiazole Phenone 0.05%, viscosity modifier glycerol 5%, pH regulator triethanolamine 0.03%, silicon polyether defoamer 0.01%, deionized water is placed in a container, mixed at normal temperature, and stirred at a speed of 2000r / min 90min, after mixing evenly, let it stand for 30min to obtain the mixed stock solution;

[0037] 2) Filter the mixed stock solution through 0.5 μm and 0.2 μm filter membranes in sequence, and retain the filtrate;

[0038] 3) The filtrate is degassed and packaged to obtain the final product.

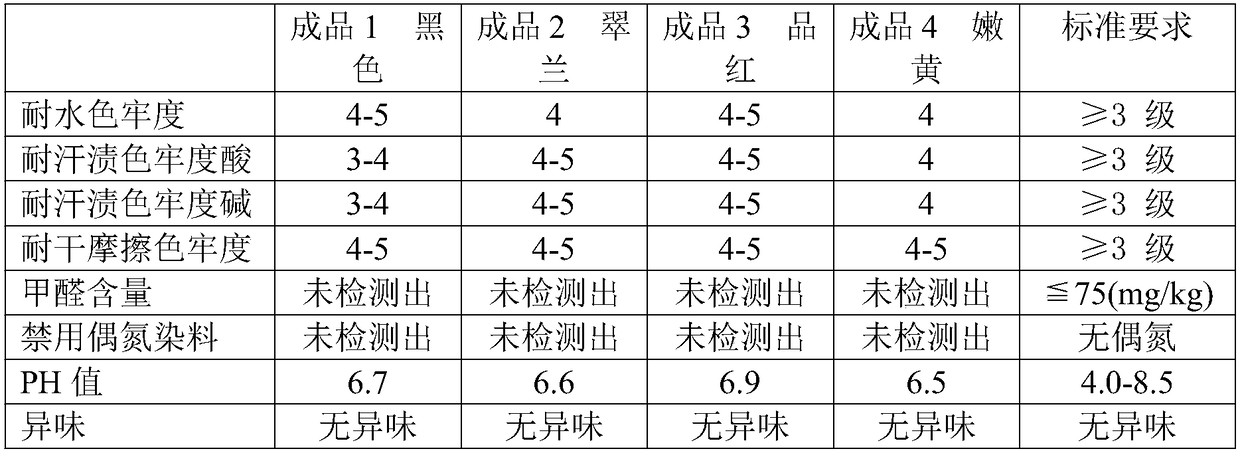

[0039] The soap-free active digital ink-jet ink prepared above is applied to the soap-free printing and dyeing process of reactive ink-jet printing on fabrics. In this embodiment, the fabric cott...

Embodiment 2

[0044] The preparation method of soap-free active digital ink-jet ink comprises the following steps:

[0045] 1) Take in turn 5% of the filtered Cuilan P-type dye, 3% of the filtered Cuilan KN-type dye, surfactant AEO-30.04%, humectant 1,2 propylene glycol 10%, polyethylene glycol 40010 %; fungicide isothiazolinone 0.5%, viscosity modifier glycerol 10%, pH regulator triethanolamine 0.03%, phthalate potassium hydrogen 0.02%, silicon polyether defoamer 0.01%, deionized water Mix in a container at room temperature, stir at a speed of 1500r / min for 90min, mix well and let stand for 30min to obtain a mixed stock solution;

[0046] 2) Filter the mixed stock solution through 0.5 μm and 0.2 μm filter membranes in sequence, and retain the filtrate;

[0047] 3) The filtrate is degassed and packaged to obtain the final product.

[0048] The soap-free active digital ink-jet ink prepared above is applied to the soap-free printing and dyeing process of reactive ink-jet printing on fabrics. ...

Embodiment 3

[0053] The preparation method of soap-free active digital ink-jet ink comprises the following steps:

[0054] 1) Get 8% of filtered red P-type dye successively, get 2% of filtered red KN-type dye, surfactant AEO-32.0%, humectant is polyethylene glycol 20015%, diethylene glycol 15%, Bactericide isothiazolinone 5%, viscosity regulator glycerol 2%, pH regulator triethanolamine 1.4%, phthalate potassium hydrogen diformate 0.6%, silicon polyether defoamer 0.05%, deionized water in the container , mixed at room temperature, stirred at a speed of 1500r / min for 90min, mixed evenly and left to stand for 30min to obtain a mixed stock solution;

[0055] 2) Filter the mixed stock solution through 0.5 μm and 0.2 μm filter membranes in sequence, and retain the filtrate;

[0056] 3) The filtrate is degassed and packaged to obtain the final product.

[0057] The soap-free active digital ink-jet ink prepared above is applied to the soap-free printing and dyeing process of reactive ink-jet pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com