Preparation process of functional lactobacillus

A production process and technology of lactic acid bacteria, applied in dairy products, medical preparations containing active ingredients, milk preparations, etc., can solve the problems that no one has studied and few products, and achieve simple process flow, unique taste, and strengthen human cells cancerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

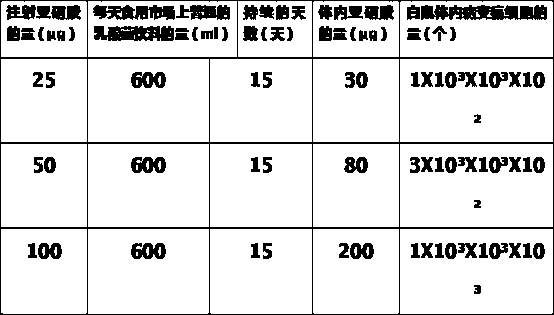

Image

Examples

Embodiment 1

[0025] Embodiment 1, with gross mass as 100kg

[0026] A. First weigh 30kg of kiwi fruit, wash the kiwi fruit, and select ripe, fresh and plump kiwi fruit;

[0027] B. Peel and destem the selected kiwi fruit;

[0028] C. Put the peeled and destemmed kiwi fruit into a blender for crushing. While adding the kiwi fruit, add pure water to mix and stir. At the same time, add 0.05kg of potassium sorbate and stir until it is observed with the naked eye. There are no large granular substances in it, just form a puree;

[0029] D. Place the obtained puree in a homogenizer with a pressure value of 30MPa, and after homogenizing for 2 minutes, obtain the homogeneous kiwi fruit puree;

[0030] E. Add the homogenized raw pulp into the batching tank, heat the batching tank, and stop heating after heating to 50 ° C ~ 60 ° C, then add 0.5kg of pectinase, stir well, and carry out the reaction of pectinase In the process, after 50 minutes of enzymolysis, heat the batching tank to 100°C, stop ...

Embodiment 2

[0036] Embodiment 2, be 120kg with gross mass

[0037] A. First weigh 42kg of kiwi fruit, wash the kiwi fruit, and select ripe, fresh and plump kiwi fruit;

[0038] B. Peel and destem the selected kiwi fruit;

[0039] C. Put the peeled and destemmed kiwi fruit into a blender for crushing. While adding the kiwi fruit, add pure water to mix and stir. At the same time, add 0.11kg of potassium sorbate and stir until it is observed with the naked eye. There are no large granular substances in it, just form a puree;

[0040] D. Place the obtained puree in a homogenizer with a pressure value of 30MPa, and after homogenizing for 2 minutes, obtain the homogeneous kiwi fruit puree;

[0041] E. Add the homogenized puree into the batching tank, heat the batching tank, and stop heating after heating to 50°C ~ 60°C, then add 0.96kg of pectinase, stir well, and carry out the reaction of pectinase In the process, after 50 minutes of enzymolysis, heat the batching tank to 100°C, stop heatin...

Embodiment 3

[0047] Embodiment 3, with total mass as 150kg

[0048] A. First weigh 60kg of kiwi fruit, wash the kiwi fruit, and select ripe, fresh and plump kiwi fruit;

[0049] B. Peel and destem the selected kiwi fruit;

[0050] C. Put the peeled and destemmed kiwi fruit into a blender for crushing. While adding the kiwi fruit, add pure water to mix and stir. At the same time, add 0.15kg of potassium sorbate and stir until it is observed with the naked eye. There are no large granular substances in it, just form a puree;

[0051] D. Place the obtained puree in a homogenizer with a pressure value of 30MPa, and after homogenizing for 2 minutes, obtain the homogeneous kiwi fruit puree;

[0052] E. Add the homogenized raw pulp into the batching tank, heat the batching tank, and stop heating after heating to 50 ° C ~ 60 ° C, then add 1.5kg of pectinase, stir well, and carry out the reaction of pectinase In the process, after 50 minutes of enzymolysis, heat the batching tank to 100°C, stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com