Preparation method of hippophae rhamnoides fruit leaf composite buccal tablets

The technology of sea buckthorn fruit and sea buckthorn leaf is applied in the field of preparation of sea buckthorn fruit and leaf compound lozenges, can solve the problems of waste, not being used effectively, polluting the environment, etc., and achieves convenience in eating, reducing the discharge of production waste and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

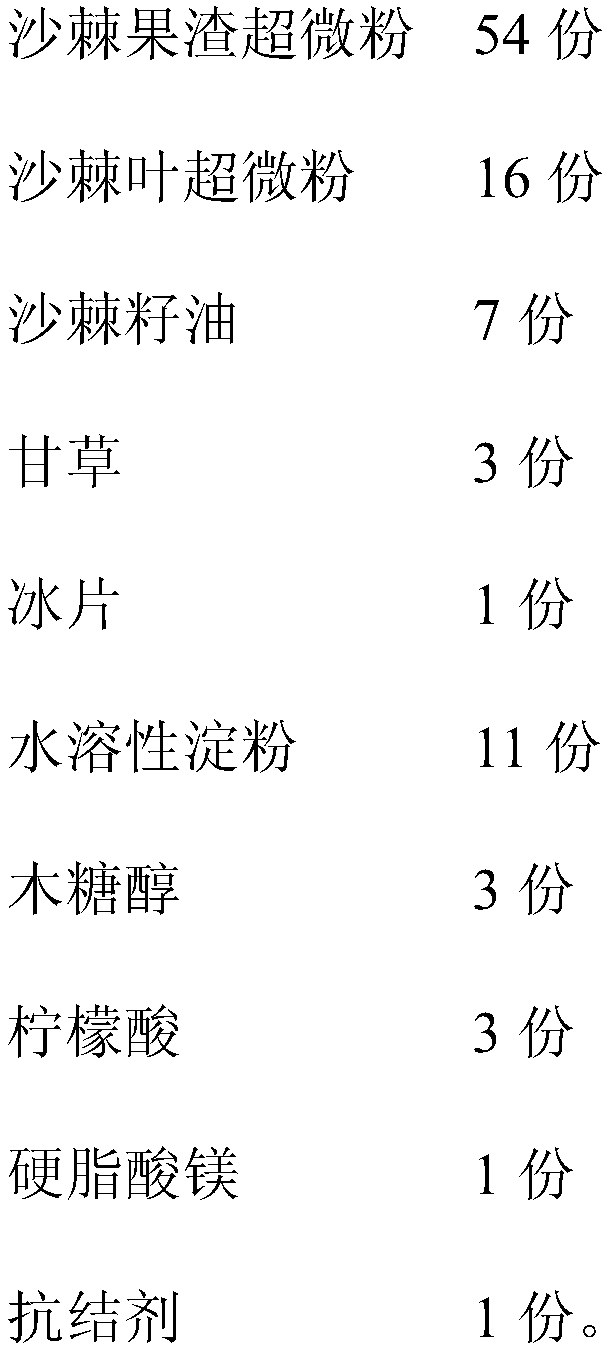

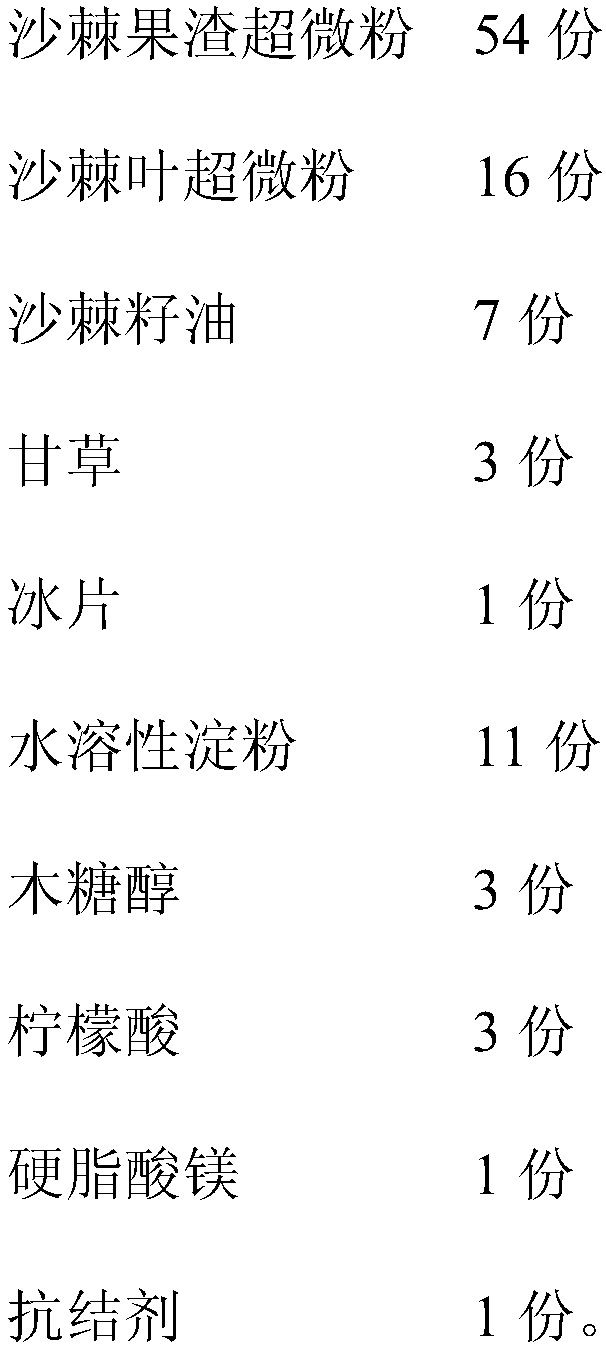

Embodiment 1

[0023] Sea buckthorn fruit and leaf compound lozenges are prepared according to the following method:

[0024] (1) Seabuckthorn pomace is washed and squeezed, and then dried in an oven for 20 minutes at a temperature of 80°C. The water content of the dried seabuckthorn pomace is 4 wt%, and it is crushed into superfine powder of seabuckthorn pomace by a wall breaking machine. , through a 20-mesh sieve, and the prepared pomace powder was baked for 20 minutes again, and the moisture content in the superfine seabuckthorn pomace powder was 2wt%;

[0025] (2) Seabuckthorn leaves are washed and dried, crushed into a particle size of 20 mesh seabuckthorn leaf superfine powder with a wall breaking machine, oven-dried for 30 minutes, the oven temperature is 60°C, and the water content in the seabuckthorn leaf superfine powder is 1.8wt%;

[0026] (3) Seabuckthorn seeds were dried at 50° C. for 24 hours, crushed and then dried to constant weight with a water content of 2 wt%. Pack the dr...

Embodiment 2

[0032] Sea buckthorn fruit and leaf compound lozenges are prepared according to the following method:

[0033] (1) Seabuckthorn pomace is washed and squeezed, and dried in an oven for 20 minutes at a temperature of 70°C. The water content of the dried seabuckthorn pomace is 5 wt%, and it is crushed into superfine powder of seabuckthorn pomace by a wall breaking machine. , through a 20-mesh sieve, and the prepared pomace powder was baked for 30 minutes again, and the moisture content in the superfine sea-buckthorn pomace powder was 1.6wt%;

[0034] (2) Seabuckthorn leaves are washed and dried, crushed into a particle size of 20 mesh seabuckthorn leaf superfine powder with a wall breaking machine, dried in an oven for 30 minutes, the oven temperature is 60 ° C, and the water content in the seabuckthorn leaf superfine powder is 1 wt %;

[0035] (3) Seabuckthorn seeds were dried at 50° C. for 24 hours, crushed and then dried to constant weight with a water content of 2 wt%. Pack ...

Embodiment 3

[0041] Sea buckthorn fruit and leaf compound lozenges are prepared according to the following method:

[0042] (1) Seabuckthorn pomace is washed and squeezed to get the seabuckthorn pomace, and dried in an oven for 20 minutes at a temperature of 80°C. The water content of the dried seabuckthorn pomace is 5wt%, and it is pulverized into superfine powder of seabuckthorn pomace by a wall breaking machine. , through a 20-mesh sieve, and the prepared pomace powder was baked for 30 minutes again, and the moisture content in the superfine sea-buckthorn pomace powder was 1.6wt%;

[0043] (2) Seabuckthorn leaves are washed and dried, crushed into a particle size of 20 mesh seabuckthorn leaf superfine powder with a wall breaking machine, dried in an oven for 30 minutes, the oven temperature is 60 ° C, and the water content in the seabuckthorn leaf superfine powder is 1 wt %;

[0044] (3) Seabuckthorn seeds were dried at 50° C. for 24 hours, crushed and then dried to constant weight with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com