A method for preparing superhydrophilic organic membranes based on nano-hydrotalcites

A hydrotalcite and organic membrane technology, applied in the field of membrane separation, can solve the problems of organic membranes being easily polluted and operating costs, and achieve excellent long-term anti-pollution performance, high-efficiency retention, and improved retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

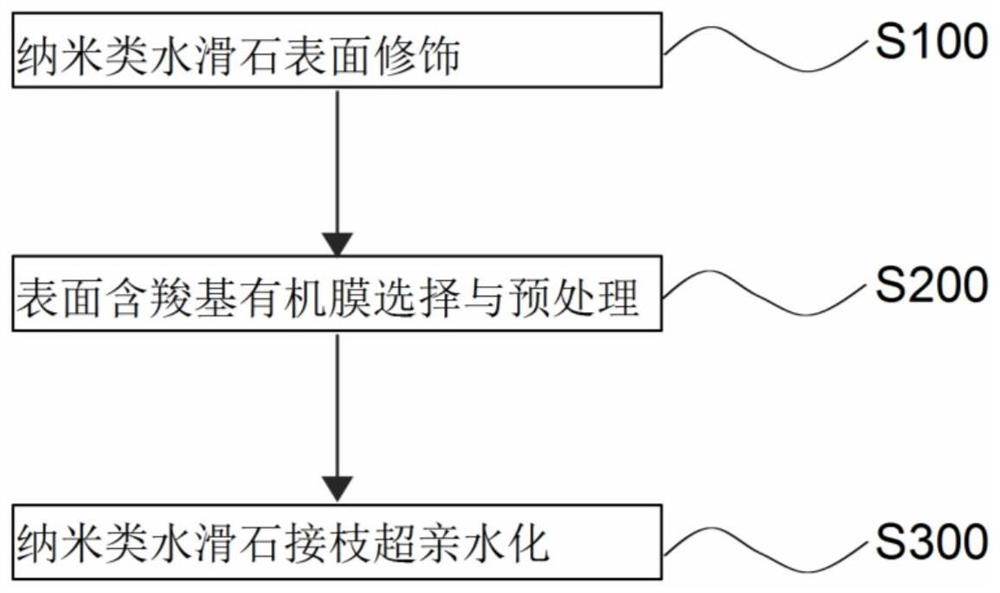

[0042] The present invention provides a method for preparing a super-hydrophilic organic membrane based on nano-like hydrotalcite. According to the embodiment of the present invention, the implementation flowchart is shown in figure 1 , which includes the following steps:

[0043] S100, nano-hydrotalcite surface modification

[0044] The nano-type hydrotalcite suspension containing amino functional groups is prepared according to the steps of the present invention. Based on the total mass of the obtained suspension, the content of the nano-type hydrotalcite is 0.1wt%-30wt%; the configured mass content is 13wt%-17wt% % magnesium nitrate and 5.6wt%-9wt% aluminum nitrate mixed aqueous solution; configure 26%-40% volume content (3-aminopropyl) triethoxysilane ethanol solution; configure at 70 degrees Celsius Aqueous sodium dodecyl sulfonate solution with mass content of 4.8wt%-8wt%; add magnesium nitrate / aluminum nitrate salt solution and (3-aminopropane) dropwise to the sodium d...

Embodiment 1

[0050] 1. Nano-hydrotalcite surface modification

[0051] To prepare the amino functional group-containing nano-hydrotalcite suspension with a mass content of 15wt%, according to the preparation steps of the present invention, the preparation conditions adopted are: the mass content of magnesium nitrate is 15wt%, and the mass content of aluminum nitrate is 7.3wt% ; The volume content of (3-aminopropyl) triethoxysilane is 33%; the mass content of sodium dodecyl sulfonate is an aqueous solution of 6.4 wt%; the mixing rate of the three solutions is 0.02 mL / s, and the mixing ratio is 4 :4:3; heated at a constant temperature of 70 degrees Celsius for 12 hours.

[0052] 2. Selection and treatment of surface carboxyl organic film

[0053] A carboxymethyl cellulose membrane was selected and immersed in a catalyst aqueous solution containing 5mmol / L N-hydroxysuccinimide, 2mmol / L 1-(3-dimethylaminopropyl)-3-ethylcarbon Diimine hydrochloride, 10 mmol / L 2-(N-morpholinyl)ethanesulfonic a...

Embodiment 2

[0058] 1. Nano-hydrotalcite surface modification

[0059] To prepare the amino functional group-containing nano-hydrotalcite suspension with a mass content of 30 wt %, according to the preparation steps of the present invention, the adopted preparation conditions are: the mass content of magnesium nitrate is 17 wt %, and the mass content of aluminum nitrate is 9 wt %; The volume content of (3-aminopropyl)triethoxysilane is 40%; the mass content of sodium dodecylsulfonate is an aqueous solution of 8wt%; the mixing rate of the three solutions is 0.1mL / s, and the mixing ratio is 4:4 : 3; heated at a constant temperature of 70 degrees Celsius for 13 hours.

[0060] 2. Selection and treatment of surface carboxyl organic film

[0061] A carboxymethyl cellulose membrane was selected and immersed in a catalyst aqueous solution containing 5mmol / L N-hydroxysuccinimide, 2mmol / L 1-(3-dimethylaminopropyl)-3-ethylcarbon Diimine hydrochloride, 10mmol / L 2-(N-morpholinyl)ethanesulfonic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com