Preparation method of denitration catalyst

A denitration catalyst and catalyst technology are applied in the field of denitration catalysts, which can solve problems such as catalyst poisoning reaction and catalyst deactivation, and achieve the effects of promoting reaction, high catalytic activity and improving destocking activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

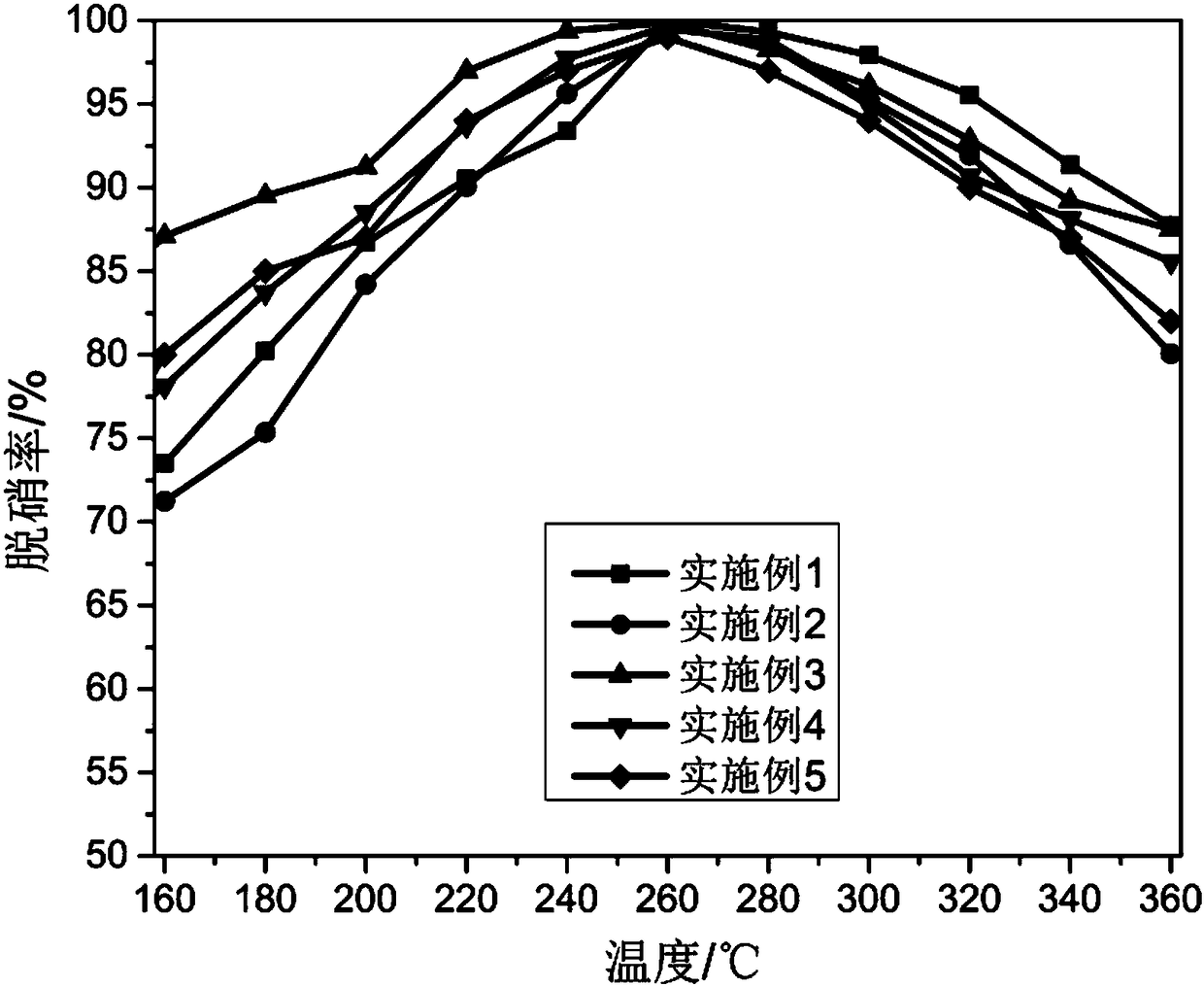

Examples

Embodiment 1

[0032] S1. Preparation of Ti sol: Mix 15wt% tetrabutyl titanate, 2wt% hexadecyltrimethylammonium bromide, and 72wt% absolute ethanol and place them in a 90kHz ultrasonic wave for 0.5h. After stirring, take 11wt% distilled water was added dropwise to the above mixed solution and placed in an ultrasonic wave to continue stirring for 0.5h. The above two stirring stages were fed with N2 at a flow rate of 10mL / min, and the stirring temperature was 20°C;

[0033] S2. Put the Ti sol treated in step S1 in an environment with a temperature of 5° C., immerse the formed foam ceramics with a pore size of 50 nm in the Ti sol for 24 hours, then take out the foam ceramics and place them in a vacuum drying oven for 4 hours, and dry them. The temperature is 110°C. During the sample drying process, the sample is placed in the rotator and turned up and down at a constant speed of 50 rpm. After the drying is completed, the moisture content is tested, and it can be taken out after passing the test;...

Embodiment 2

[0041] S1. Preparation of Ti sol: Take 17wt% tetrabutyl titanate, 5wt% cetyltrimethylammonium bromide, 65wt% absolute ethanol and mix them in a 70kHz ultrasonic wave for 1h. After the stirring is completed, take 13wt% distilled water was added dropwise to the above mixed solution and placed in an ultrasonic wave to continue stirring for 0.5h. The above two stirring stages were fed with N at a flow rate of 30mL / min. 2 , the stirring temperature is 20°C;

[0042] S2. Put the Ti sol treated in step S1 in an environment with a temperature of 5° C., immerse the formed foam ceramics with a pore size of 60 nm in the Ti sol for 20 hours, then take out the foam ceramics and place them in a vacuum drying oven for 6 hours, and dry them. The temperature is 120°C. During the sample drying process, the sample is placed in the rotator and turned up and down at a constant speed of 70 rpm. During the sample drying process, the sample is placed in the rotator and turned up and down at a constan...

Embodiment 3

[0050] S1. Preparation of Ti sol: Mix 20wt% tetrabutyl titanate, 7wt% hexadecyltrimethylammonium bromide, and 60wt% absolute ethanol and place them in a 100kHz ultrasonic wave for 1 hour. After stirring, take 13wt % distilled water was added dropwise to the above mixed solution and placed in an ultrasonic wave to continue stirring for 1 h. The above two stirring stages were fed with N at a flow rate of 50 mL / min. 2 , the stirring temperature is 25°C;

[0051] S2. Put the Ti sol treated in step S1 in an environment with a temperature of 15° C., immerse the formed foam ceramics with a pore size of 50 nm in the Ti sol for 15 hours, then take out the foam ceramics and place them in a vacuum drying oven for 8 hours, and dry them. The temperature is 130°C. During the sample drying process, the sample is placed in the rotator and turned up and down at a constant speed of 60 rpm. During the sample drying process, the sample is placed in the rotator and turned up and down at a constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com