High temperature resistant ceramic pot

A ceramic pot and high-temperature-resistant technology, which is applied in the field of ceramic products, can solve the problems of easy bursting or cracks, ceramic products are not durable, bursting, etc., and achieve the effect of good strength, high density, and safe and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

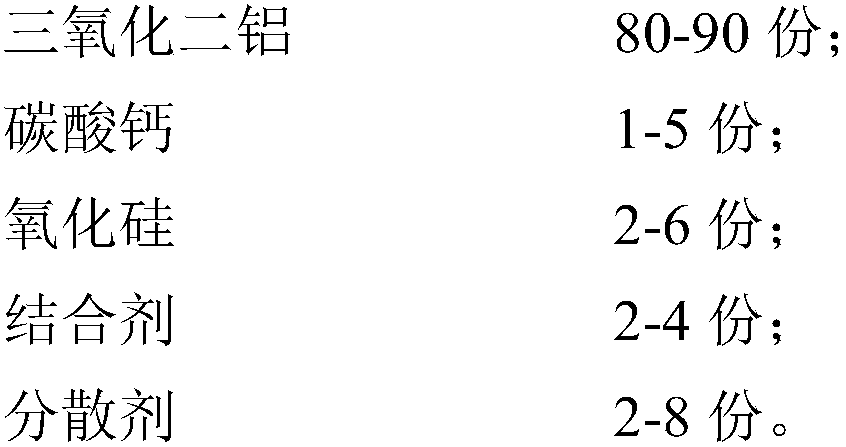

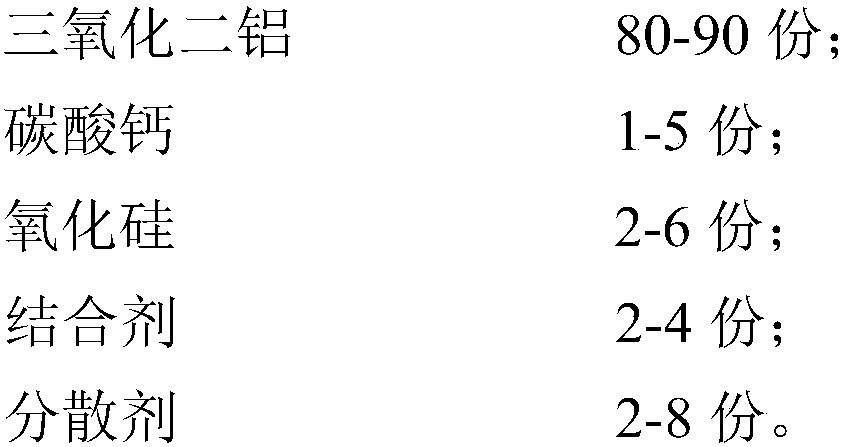

Method used

Image

Examples

Embodiment 1

[0020] A kind of high temperature resistant ceramic pot, the preparation method of described ceramic pot comprises the steps:

[0021] (1) First put 80 parts of aluminum oxide, 5 parts of calcium carbonate, 6 parts of silicon oxide, 2 parts of binder, and 8 parts of stearic acid into a ball mill, add 50 parts of deionized water, and use a speed of 40 rpm The raw materials are ground and mixed evenly at a rotating speed to form a paste slurry; the binder consists of 35 parts of polyethylene, 5 parts of polystyrene, 8 parts of acrylic acid, 4 parts of microcrystalline paraffin, 5 parts of fumed white carbon black, 2 parts Soybean oil, each raw material is weighed and mixed, and placed under microwave treatment for 15 minutes; the amount of each raw material is calculated in parts by weight;

[0022] (2) Adopt spray drier to make pasty slurry into particles whose average particle diameter is 0.5mm;

[0023] (3) Fill the particles obtained in step (2) into the abrasive, and then ...

Embodiment 2

[0026] A kind of high temperature resistant ceramic pot, the preparation method of described ceramic pot comprises the steps:

[0027] (1) First put 90 parts of aluminum oxide, 1 part of calcium carbonate, 4 parts of silicon oxide, 3 parts of binder, and 6 parts of vaseline into the ball mill, add 60 parts of deionized water, and grind the mixture at a speed of 40 rpm. The raw materials are ground and mixed evenly to form a paste slurry; the binder consists of 20 parts of polyethylene, 10 parts of polystyrene, 5 parts of acrylic acid, 6 parts of microcrystalline paraffin, 15 parts of fumed white carbon black, and 4 parts of soybean oil , after weighing each raw material and mixing, place it under microwave treatment for 20 minutes; the amount of each raw material is calculated in parts by weight;

[0028] (2) adopt spray drier to make pasty slurry into particles whose average particle diameter is 0.3mm;

[0029] (3) the particles obtained in step (2) are filled in the grindin...

Embodiment 3

[0032] A kind of high temperature resistant ceramic pot, the preparation method of described ceramic pot comprises the steps:

[0033] (1) First put 85 parts of aluminum oxide, 4 parts of calcium carbonate, 2 parts of silicon oxide, 4 parts of binder, and 2 parts of silicone oil into a ball mill, add 55 parts of deionized water, and put the The raw materials are ground and mixed evenly to form a paste slurry; the binder consists of 30 parts of polyethylene, 8 parts of polystyrene, 10 parts of acrylic acid, 8 parts of microcrystalline paraffin, 10 parts of fumed white carbon black, and 3 parts of soybean oil , after weighing each raw material and mixing, place it under microwave treatment for 15 minutes; the amount of each raw material is calculated in parts by weight;

[0034] (2) adopt spray drier to make pasty slurry into particles whose average particle diameter is 0.4mm;

[0035] (3) Fill the particles obtained in step (2) into the abrasive, and then 600kgf / cm 2 Pressed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap