A kind of preparation method and graphite product of mold compression molding graphite product

A graphite product and mold pressing technology, applied in the field of mold pressing and forming graphite product preparation, can solve the problems of slow molding method, long processing time, high cost of manpower and material resources, and achieve the improvement of various performance indicators, low porosity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

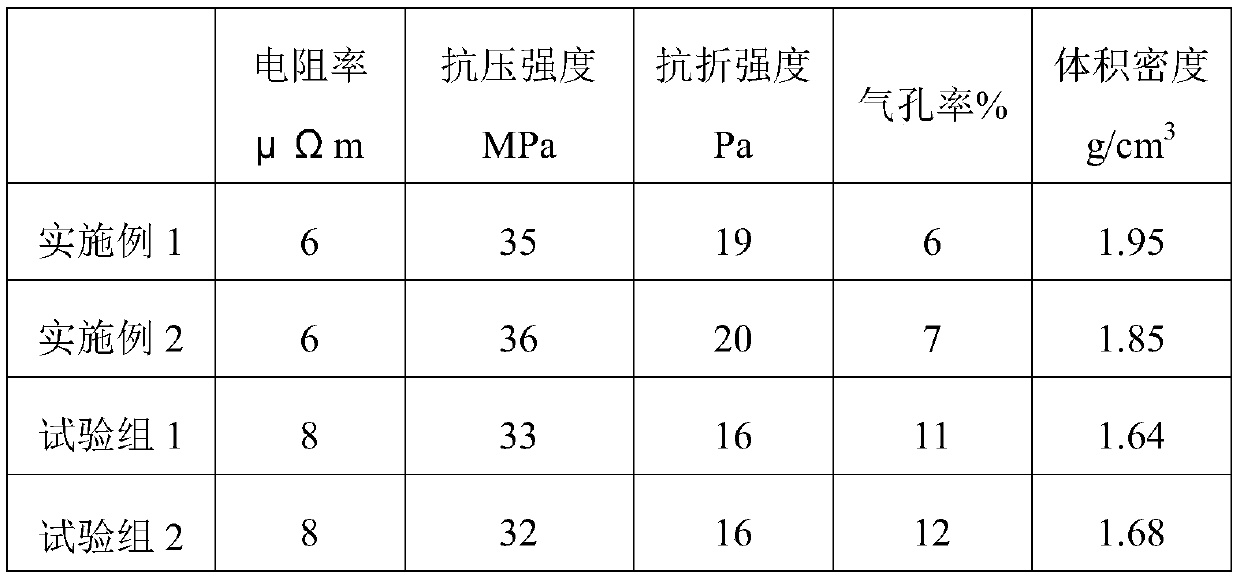

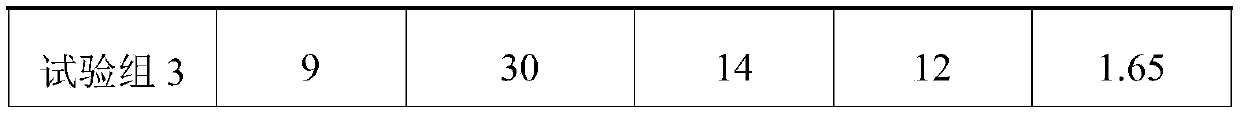

Embodiment 1

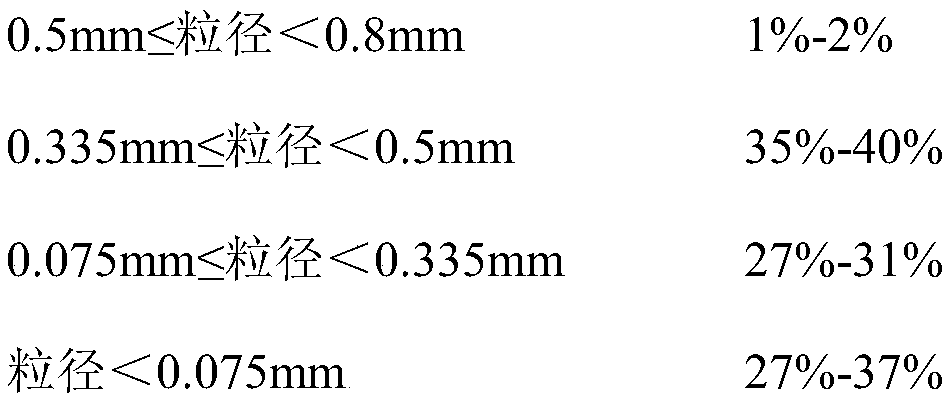

[0044] (1) Crushing, sieving, and batching: crush the calcined petroleum coke, and sieve it into specifications of 0.5mm<particle size≤0.8mm, 0.335mm<particle size≤0.5mm, 0.075mm<particle size≤0.335mm and Four kinds of fine powder particles <0.075mm; crush and sieve the pitch coke to obtain particles with a specification of 0.335mm<particle size≤0.5mm; then take 75 parts by weight of calcined coke, 20 parts by weight of pitch coke, and the specification is 0.075mm< 5 parts by weight of needle coke with a particle diameter of ≤0.335 mm are used for batching.

[0045] Among the above 75 parts by weight of calcined coke: calcined coke with 0.5mm<particle size≤0.8mm accounts for 2% of the total weight of calcined coke, and calcined coke with 0.335mm<particle size≤0.5mm accounts for 40% of the total weight of calcined coke Calcined coke with a particle diameter of 0.075mm<0.335mm accounts for 31% of the total calcined coke weight, and calcined coke with a particle diameter<0.075mm ...

Embodiment 2

[0057] (1) Crushing, sieving, and batching: crush the calcined petroleum coke, and sieve it into specifications of 0.5mm<particle size≤0.8mm, 0.335mm<particle size≤0.5mm, 0.075mm<particle size≤0.335mm and Four kinds of fine powder particles <0.075mm; crush and sieve the pitch coke to obtain particles with a specification of 0.335mm<particle size≤0.5mm; then take 77 parts by weight of calcined coke, 15 parts by weight of pitch coke, and the specification is 0.075mm< 8 parts by weight of needle coke with a particle diameter of ≤0.335 mm are used for batching.

[0058] Wherein, among the above-mentioned 77 parts by weight of calcined coke: calcined coke with 0.5mm

Embodiment 3

[0070] (1) Crushing, sieving, and batching: crush the calcined petroleum coke, and sieve it into specifications of 0.5mm<particle size≤0.8mm, 0.335mm<particle size≤0.5mm, 0.075mm<particle size≤0.335mm and Four kinds of fine powder particles <0.075mm; crush and sieve the pitch coke to obtain particles with a specification of 0.335mm<particle size≤0.5mm; then take 76 parts by weight of calcined coke, 19 parts by weight of pitch coke, and the specification is 0.075mm< 7 parts by weight of needle coke with a particle diameter of ≤0.335 mm are used for batching.

[0071] Wherein, among the above-mentioned 76 parts by weight of calcined coke: calcined coke with 0.5mm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com