Method for producing amylene through 2-amyl alcohol dehydration

A technology of n-pentene and pentanol, applied in the field of dehydration of 2-pentanol to produce n-pentene, which can solve the problems of long process route and low purity of 1-pentene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

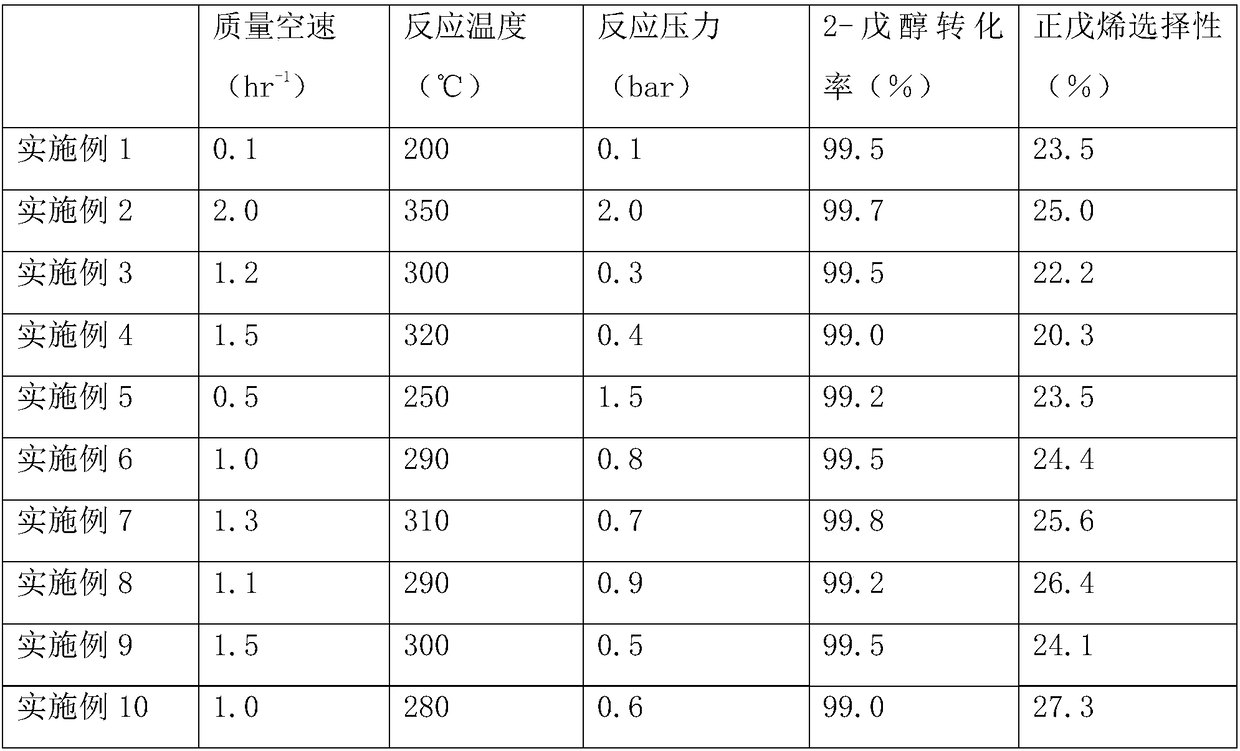

Embodiment 1~10

[0016] 1. Dehydration reaction of 2-pentanol

[0017] The dehydration reaction is carried out in a tubular fixed-bed reactor with a size of φ25mm×1500mm. The reactor is filled with γ-Al with a particle size of 3-5mm 2 o 3 100 g of catalyst constitutes a fixed bed catalyst bed. The outside of the reactor is equipped with a temperature-controlled jacket of circulating heat-conducting oil, and platinum resistors for temperature measurement are respectively installed on the upper, middle and lower parts of the catalyst bed. The amount of reaction feed is controlled by a feed pump, and the system pressure is regulated by a back pressure valve.

[0018] 2-pentanol is reacted through a tubular fixed-bed reactor according to the set feed amount, and dehydration is carried out according to the set reaction conditions; 2-pentanol is converted into 1-pentene and 2-pentene through the dehydration reaction alkene; the dehydration reaction products obtained in Examples 1-10 were analyze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com