Method using ionic liquid for gas drying and dehydration

An ionic liquid and gas drying technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of high regeneration energy consumption, complex systems, and easy contamination, and achieve corrosion avoidance, simple equipment, and good quality. The effect of the dehydrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

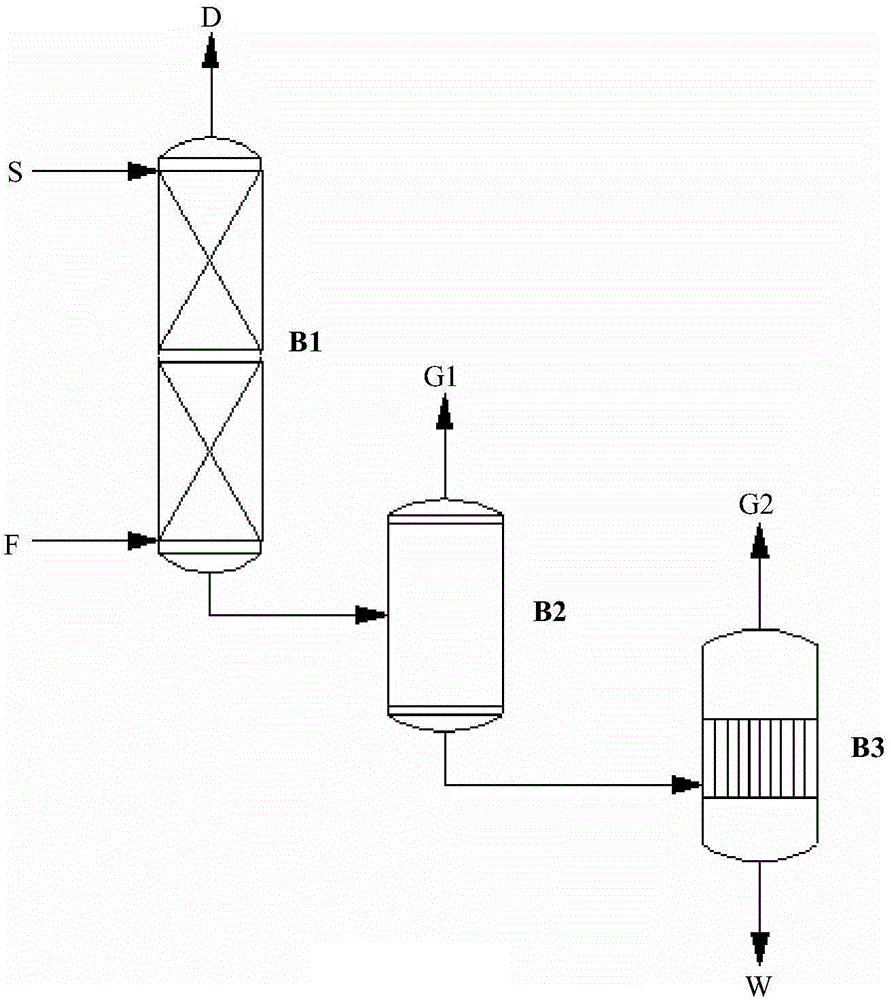

[0015] Such as figure 1 The absorption process shown. The operating conditions of the absorption tower are temperature 25℃, pressure 2.5MPa, absorption tower has 10 theoretical trays, and the feed gas is CO containing 0.2% (mole fraction) of water. 2 Gas, fed from the bottom of the tower, with a mass flow rate of 3890kg / h, with ionic liquid [EMIM] + [Tf 2 N] - (1-Ethyl-3-methylimidazole bistrifluoromethanesulfonimide) is added from the top of the tower as an absorbent, the mass flow is 2000kg / h, and CO is obtained from the top of the tower 2 The water content in the product is 19.3ppm, and the bottom of the tower is rich in [EMIM] + [Tf 2 N] - The raffinate phase enters the gas-liquid separator, and the gas-liquid separator is operated at room temperature and pressure to remove [EMIM] + [Tf 2 N] - Small amount of CO in 2 The gas and the remaining liquid of the kettle flow into the flash tank to remove [EMIM] + [Tf 2 N] - The water in the flash tank is operated at a temperature of...

Embodiment 2

[0024] Such as figure 1 The absorption process shown. The operating conditions of the absorption tower are temperature 25℃, pressure 2.5MPa, absorption tower has 10 theoretical trays, and the feed gas is CO containing 0.2% (mole fraction) of water. 2 Gas, fed from the bottom of the tower, with a mass flow rate of 3890kg / h, with ionic liquid [EMIM] + [Tf 2 N] - To add the absorbent from the top of the tower, the mass flow rate is 2500kg / h, and CO is obtained from the top of the tower 2 The water content in the product is 18.8ppm, and the bottom of the tower is rich in [EMIM] + [Tf 2 N] - The raffinate phase enters the gas-liquid separator, and the gas-liquid separator is operated at room temperature and pressure to remove [EMIM] + [Tf 2 N] - Small amount of CO in 2 The gas and the remaining liquid of the kettle flow into the flash tank to remove [EMIM] + [Tf 2 N] - The water in the flash tank is operated at a temperature of 140°C and a pressure of 0.05 atm. The bottom of the flash...

Embodiment 3

[0031] Such as figure 1 The absorption process shown. The operating conditions of the absorption tower are temperature 25℃, pressure 2.5MPa, absorption tower has 10 theoretical trays, and the feed gas is CO containing 0.2% (mole fraction) water 2 Gas, fed from the bottom of the tower, with a mass flow rate of 3890kg / h, with ionic liquid [EMIM] + [Tf 2 N] - To add the absorbent from the top of the tower, the mass flow rate is 2500kg / h, the top of the tower gets CO 2 The water content in the product is 16.2ppm, and the bottom of the tower is rich in [EMIM] + [Tf 2 N] - The raffinate phase enters the gas-liquid separator, and the gas-liquid separator is operated at room temperature and pressure to remove [EMIM] + [Tf 2 N] - A small amount of gas in the reactor, the residual liquid of the kettle flows into the flash tank to remove [EMIM] + [Tf 2 N] - The water in the flash tank is operated at a temperature of 145°C and a pressure of 0.05 atm. The bottom of the flash tank is extracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com