Low-temperature heat sealing EVA emulsion, and preparation method and use thereof

A low-temperature heat-sealing and emulsion technology, which is applied in the direction of coating, etc., can solve the problems of poor low-temperature heat-sealing performance, large damage, and high sealing temperature, and achieve good heat-sealing uniformity, reduced production energy consumption, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

[0026] 1. Preparation of raw materials:

[0027] (1) Add 75kg of soft water and 4kg of initiator in the No. 1 batching tank, stir at 800r / min after heating up to 75°C, and make an initiator solution and keep it warm.

[0028] (2) Add 75kg of demineralized water and 7kg of emulsifier in No. 2 batching tank, stir with 800r / min after heating up to 75°C, make emulsifier solution and keep it warm.

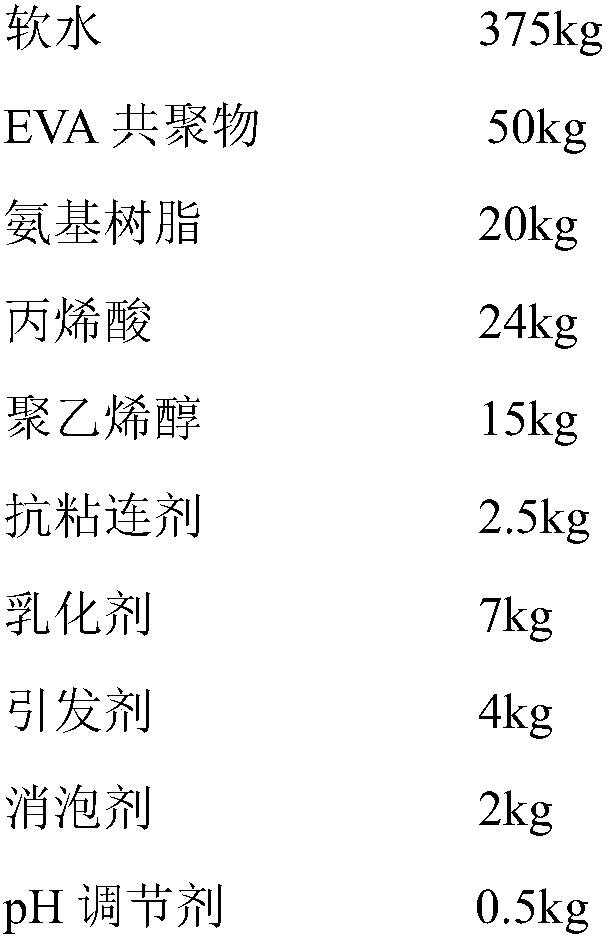

[0029] (3) Add 225kg soft water, 50kg EVA copolymer, 20kg amino resin, 24kg acrylic acid and 15kg polyvinyl alcohol in the reactor.

[0030] 2. Coating emulsification reaction:

[0031] (1) Close the inlet and outlet valves of the reactor, turn on the vacuum pump to evacuate the reactor, and when the pressure reaches -0.08MPa, pass nitrogen to normal atmospheric pressure, and replace it 3 times by vacuuming→adding nitrogen→vacuumizing. The oxygen in the reactor was completely purged.

[0032] (2) The reaction kettle is turned on and heated, and stirred at a stirring speed...

Embodiment 2

[0035]

[0036] 3. Preparation of raw materials:

[0037] (1) Add 30.4kg of soft water and 2kg of initiator into the No. 1 batching tank, stir at 800r / min after heating up to 80°C, and make an initiator solution and keep it warm.

[0038] (2) Add 30.4kg of soft water and 2.4kg of emulsifier in No. 2 batching tank, stir at 800r / min after heating up to 80°C, make emulsifier solution and keep it warm.

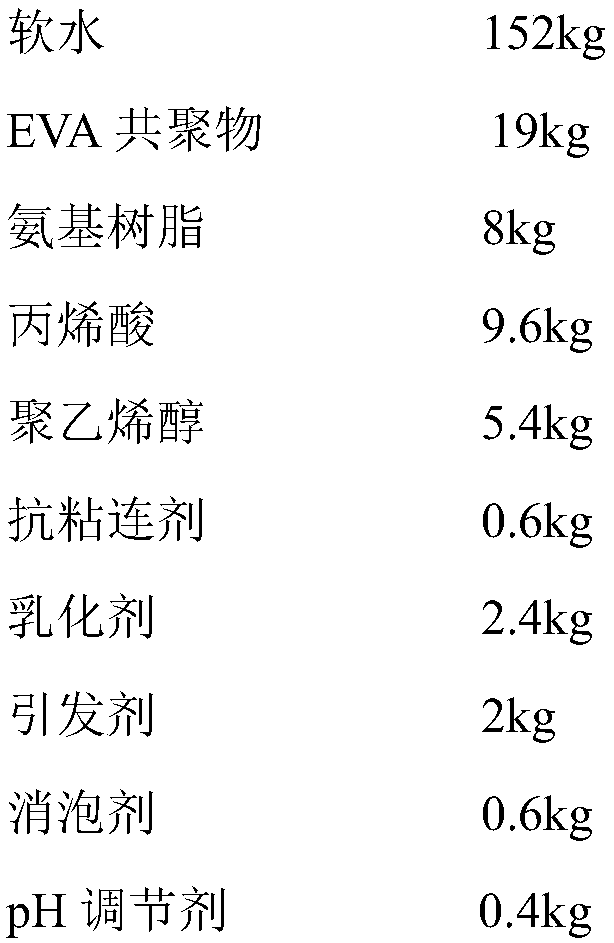

[0039] (3) Add 91.2kg of soft water, 19kg of EVA copolymer, 8kg of amino resin, 9.6kg of acrylic acid and 5.4kg of polyvinyl alcohol in the reactor.

[0040] 4. Coating emulsification reaction:

[0041] (1) Close the inlet and outlet valves of the reactor, turn on the vacuum pump to evacuate the reactor, and when the pressure reaches -0.08MPa, pass nitrogen to normal atmospheric pressure, and replace it 3 times by vacuuming→adding nitrogen→vacuumizing. The oxygen in the reactor was completely purged.

[0042] (2) The reaction kettle is turned on and heated, and stirred at a ...

Embodiment 3

[0045]

[0046] 5. Preparation of raw materials:

[0047] (1) Add 53.9kg of soft water and 2.1kg of initiator in the No. 1 batching tank, stir at 800r / min after heating up to 60°C to make an initiator solution and keep it warm.

[0048] (2) Add 53.9kg of soft water and 5.25kg of emulsifier in No. 2 batching tank, stir at 800r / min after heating up to 60°C, make emulsifier solution and keep it warm.

[0049] (3) Add 161.7kg of soft water, 33.95kg of EVA copolymer, 11.9kg of amino resin, 12.25kg of acrylic acid and 10.5kg of polyvinyl alcohol in the reactor.

[0050] 6. Coating emulsification reaction:

[0051] (1) Close the inlet and outlet valves of the reactor, turn on the vacuum pump to evacuate the reactor, and when the pressure reaches -0.08MPa, pass nitrogen to normal atmospheric pressure, and replace it 3 times by vacuuming→adding nitrogen→vacuumizing. The oxygen in the reactor was completely purged.

[0052](2) The reaction kettle is turned on and heated, and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com