Terminal hydroxy-carboxy bifunctional saturated polyester resin and preparation method thereof

A technology of polyester resin and bifunctional group, which is applied in the field of hydroxyl-terminated carboxyl bifunctional saturated polyester resin and its preparation, and can solve problems such as low weather resistance, difficulty in accurately controlling product parameters, and inapplicability of polyester resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

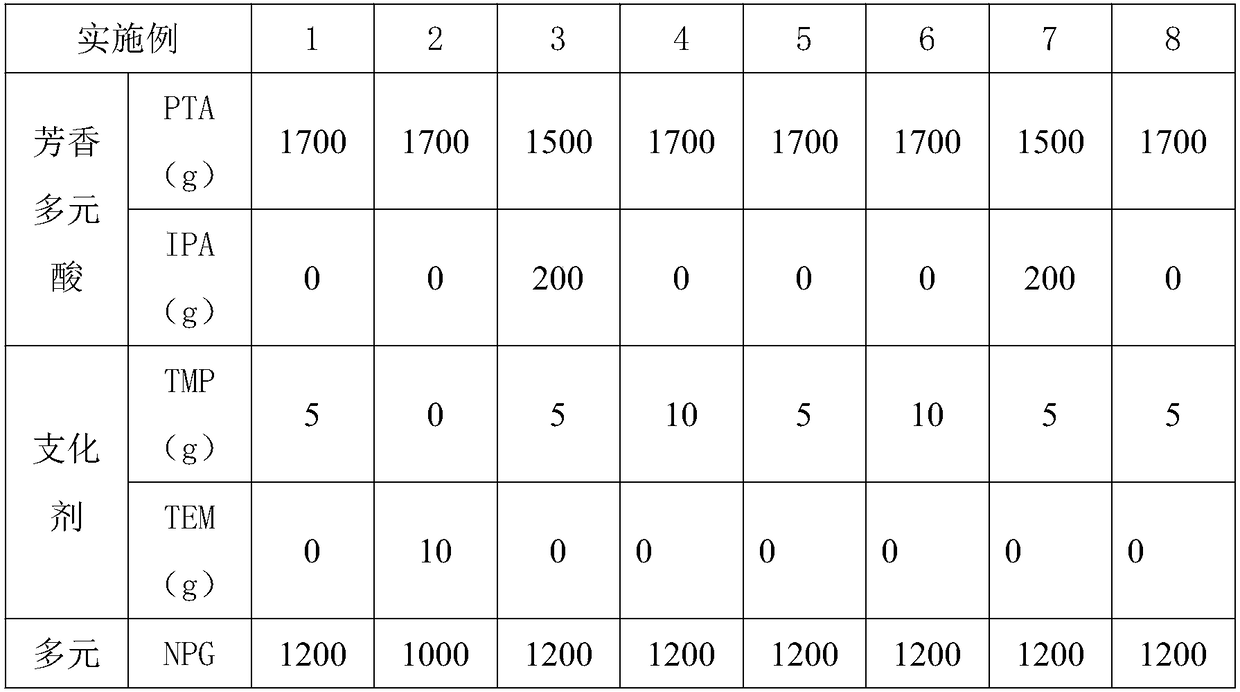

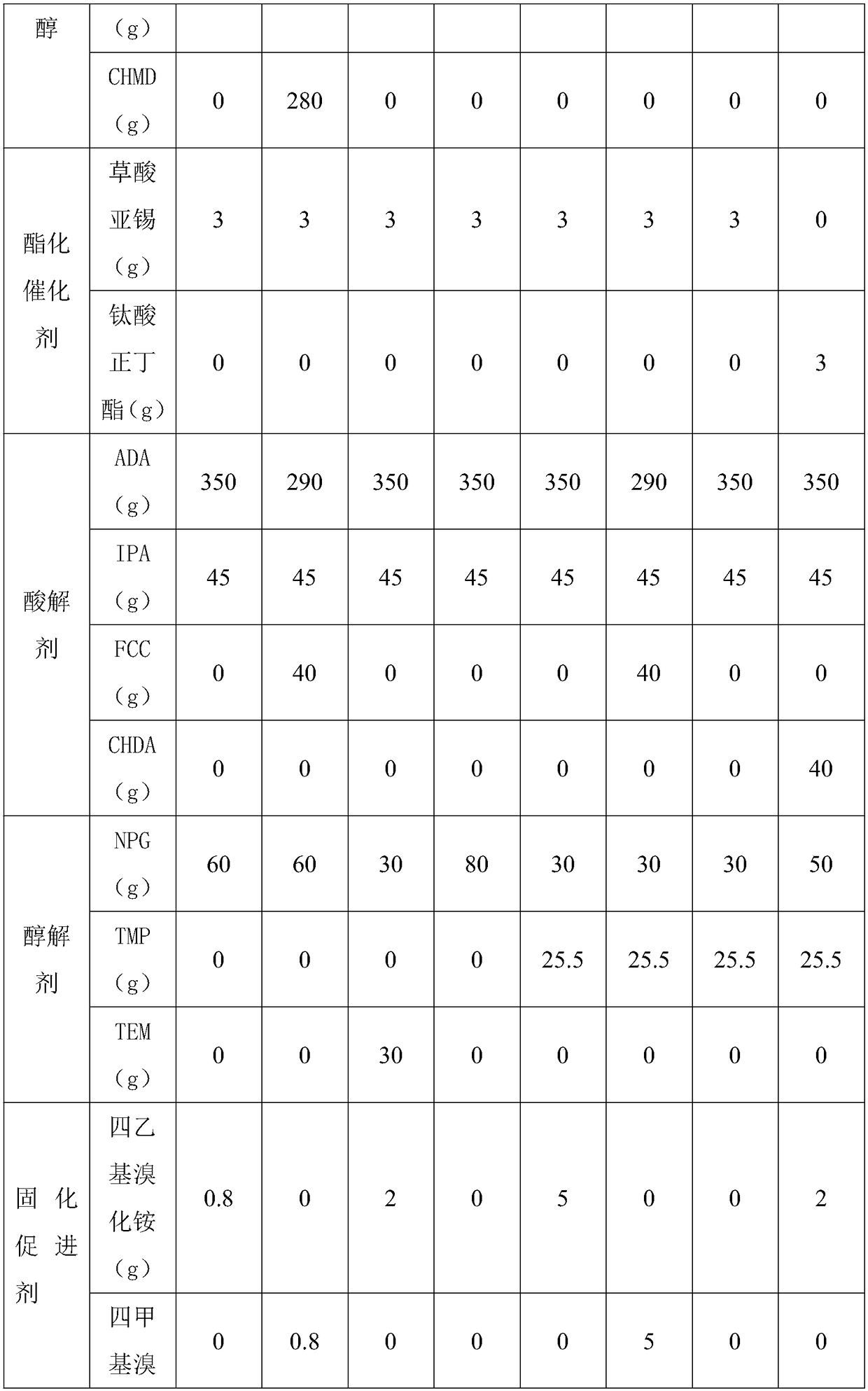

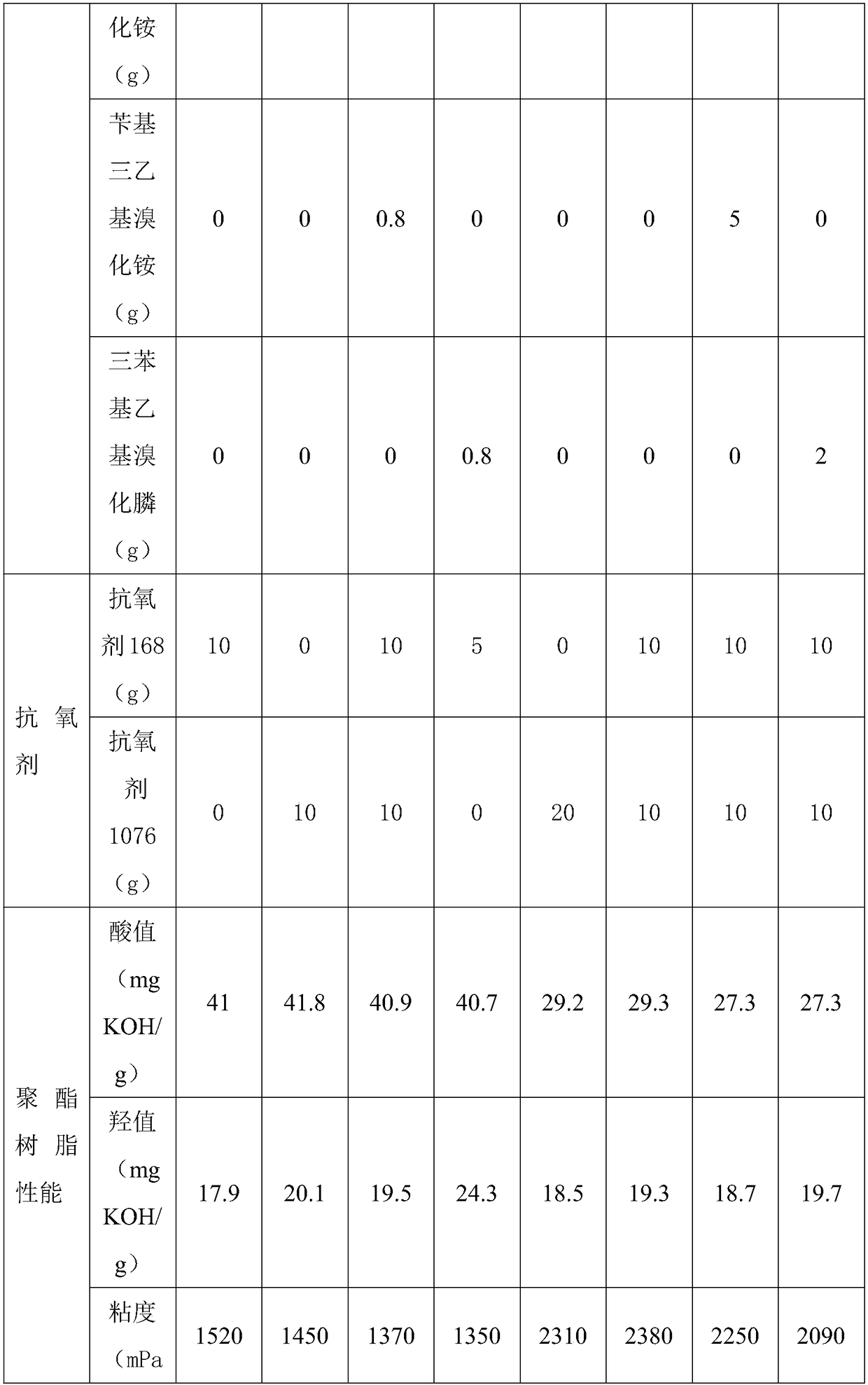

Examples

Embodiment 1

[0026] The preparation method step of polyester resin is as follows:

[0027] A. Put polyol and branching agent in the reaction kettle, heat and melt in nitrogen atmosphere, then add aromatic polyacid and esterification catalyst, carry out esterification and polycondensation reaction at 245°C until the acid value of the reaction intermediate product is 10mgKOH / g;

[0028] B. Add an acidolysis agent to carry out polycondensation and end-capping at 240°C. When the acid value reaches 55mgKOH / g, cool down to 235°C and then vacuum polycondensate to form a polyester resin intermediate. The acid value of the polyester resin intermediate is 46mgKOH / g ; The degree of vacuum of the vacuum is -0.1MPa;

[0029] C, the alcoholysis agent is dropped into the reactor and maintained to an acid value of 41mgKOH / g, and a hydroxyl value of 17.9mgKOH / g;

[0030] D. Cool down to 200°C, put in curing accelerator and antioxidant, and keep for 20 minutes to obtain polyester resin.

Embodiment 2

[0032] The preparation method step of polyester resin is as follows:

[0033] A. Put polyols and branching agents in a reaction kettle, heat and melt them in a nitrogen atmosphere, then add aromatic polyacids and esterification catalysts, and carry out esterification and polycondensation at 235°C until the acid value of the reaction intermediate product is 13mgKOH / g;

[0034] B. Add an acidolysis agent to carry out polycondensation and end-capping at 235°C. When the acid value reaches 60mgKOH / g, cool down to 230°C and then vacuum polycondensate to form a polyester resin intermediate. The acid value of the polyester resin intermediate is 48mgKOH / g ; The degree of vacuum of the vacuum is -0.1MPa;

[0035] C, the alcoholysis agent is dropped into the reactor and maintained to an acid value of 41.8mgKOH / g, and a hydroxyl value of 20.1mgKOH / g;

[0036] D. Cool down to 190°C, put in curing accelerator and antioxidant, and keep for 25 minutes to obtain polyester resin.

Embodiment 3

[0038] The preparation method step of polyester resin is as follows:

[0039] A. Put polyols and branching agents in a reaction kettle, heat and melt them in a nitrogen atmosphere, then add aromatic polyacids and esterification catalysts, and carry out esterification and polycondensation at 250°C until the acid value of the reaction intermediate product is 7mgKOH / g;

[0040] B. Add an acidolysis agent to carry out polycondensation and end-capping at 248°C. When the acid value reaches 62mgKOH / g, cool down to 240°C and then vacuum polycondensate to form a polyester resin intermediate. The acid value of the polyester resin intermediate is 52mgKOH / g ; The degree of vacuum of the vacuum is -0.1MPa;

[0041] C, the alcoholysis agent is dropped into the reactor and maintained to an acid value of 40.9mgKOH / g, and a hydroxyl value of 19.5mgKOH / g;

[0042] D. Cool down to 190°C, add curing accelerator and antioxidant, and keep for 10 minutes to obtain polyester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com