Photovoltaic waterproof coiled material for roof and preparing method

A waterproof membrane and waterproof membrane layer technology, which is applied to roofs, roof coverings, and roofs using flexible materials, etc., can solve problems such as increasing building load-bearing and high-rise wind exposure risks, damaging roof waterproofing layers, and affecting architectural beauty. , to achieve the effect of avoiding water seepage on the roof, prolonging the service life, and creating a safe and comfortable living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

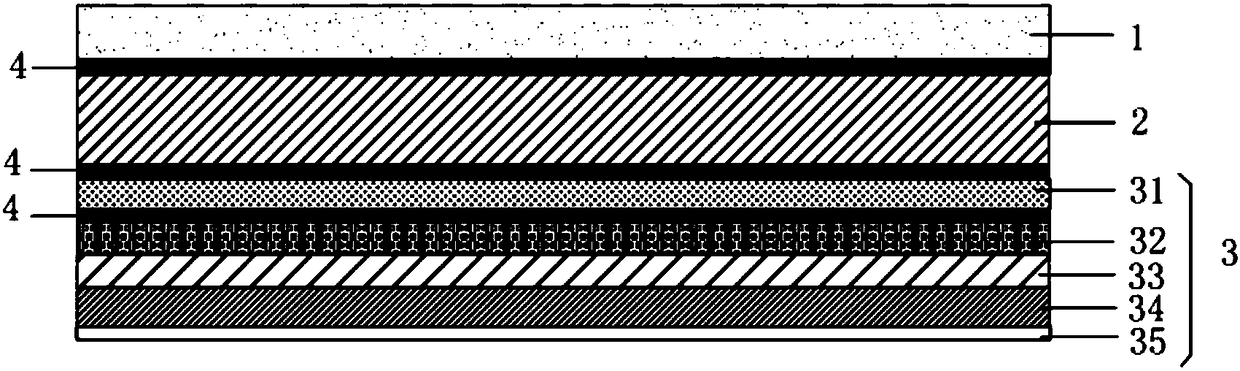

[0035] Such as figure 1 Shown, a kind of roof photovoltaic waterproof roll material and preparation method of the preferred embodiment of the present invention;

[0036] The photovoltaic waterproof coiled material for the roof, the waterproof coiled material sequentially includes a waterproof protective layer 1, a flexible photovoltaic module layer 2 and a waterproof coiled material layer 3 from top to bottom, and the layers are bonded by an adhesive 4;

[0037]The waterproof protective layer 1 is a graphene modified PET transparent waterproof layer, including the following components in parts by weight: 60 parts of PET, 12 parts of diisocyanate, 4 parts of nano-titanium dioxide, 1.0 parts of graphene, 13 parts of plasticizer, 5 parts of curing agent, 3 parts of anti-aging agent;

[0038] The flexible photovoltaic module 2 includes a flexible thin film photovoltaic module, an ethylene-tetrafluoroethylene copolymer film layer and a graphene-organosilicon modified polyacrylamid...

Embodiment 2

[0052] A photovoltaic waterproof membrane for roofs and a preparation method thereof according to a preferred embodiment of the present invention;

[0053] The photovoltaic waterproof membrane for the roof, the waterproof membrane includes a waterproof protective layer, a flexible photovoltaic module layer and a waterproof membrane layer from top to bottom, and the layers are bonded by an adhesive;

[0054] The waterproof protective layer is a graphene modified PET transparent waterproof layer, including the following components in parts by weight: 50 parts of PET, 10 parts of diisocyanate, 3 parts of nano-titanium dioxide, 0.8 parts of graphene, 10 parts of plasticizer, solidified 3 parts of anti-aging agent, 2 parts of anti-aging agent;

[0055] The flexible photovoltaic module includes a flexible thin film photovoltaic module, an ethylene-tetrafluoroethylene copolymer film layer and a graphene-organosilicon modified polyacrylamide coating layer, and the flexible thin film p...

Embodiment 3

[0068] A photovoltaic waterproof membrane for roofs and a preparation method thereof according to a preferred embodiment of the present invention;

[0069] The photovoltaic waterproof membrane for the roof, the waterproof membrane includes a waterproof protective layer, a flexible photovoltaic module layer and a waterproof membrane layer from top to bottom, and the layers are bonded by an adhesive;

[0070] The waterproof protective layer is a graphene modified PET transparent waterproof layer, including the following components in parts by weight: 70 parts of PET, 15 parts of diisocyanate, 5 parts of nano titanium dioxide, 1.5 parts of graphene, 15 parts of plasticizer, curing 8 parts of anti-aging agent and 5 parts of anti-aging agent;

[0071] The flexible photovoltaic module includes a flexible thin film photovoltaic module, an ethylene-tetrafluoroethylene copolymer film layer and a graphene-organosilicon modified polyacrylamide coating layer, and the flexible thin film ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com