Preparation technology of silicon-carbon composite negative electrode material

A technology of negative electrode material and preparation process, applied in the field of preparation of silicon-carbon composite negative electrode material, can solve the problems of high cost and difficulty in large-scale application, and achieve the effects of good stability, protection stability and increased cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

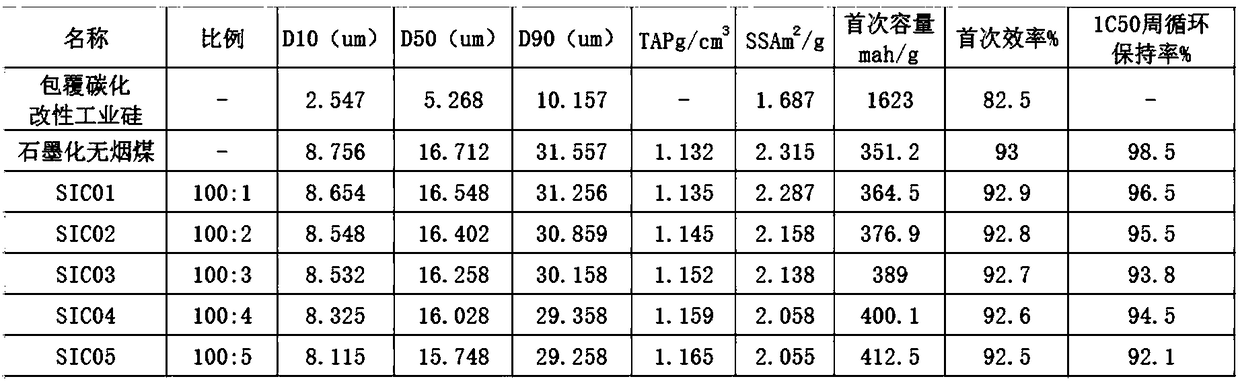

[0013] The preparation process of the silicon-carbon composite negative electrode material in this embodiment, the specific steps are as follows:

[0014] (1) Prepare raw materials: auxiliary materials: Silicon adopts industrial silicon prepared from silicon dioxide on the market as raw material, with a purity of more than 99.5%. After being pulverized by high-pressure airflow, it is pulverized to a medium particle size of 5um. The purity of industrial silicon is 99.5% to produce glucose; the ratio of fluorocarbon resin is 100:8:4, and the high-speed mixer is coated for 15 minutes. Temperature curve High-temperature carbonization for 12 hours Equipment operating parameters Propelling speed: 1.0-1.5m / h; Temperature: 900-1100℃; Gas type: Nitrogen Total pressure: 5-7KPa, cooling, mixing, breaking up and blending materials for use; main ingredients: The main material is anthracite anode material technology, which is produced through raw materials, crushing and shaping, graphitizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com