Alkaline anion exchange membrane fuel cell anode nano-catalyst, preparation and application

A nano-catalyst, alkaline anion technology, used in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of increasing and hindering AAEMFC, and achieve large specific surface area, simple process, good dispersibility and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] preparation:

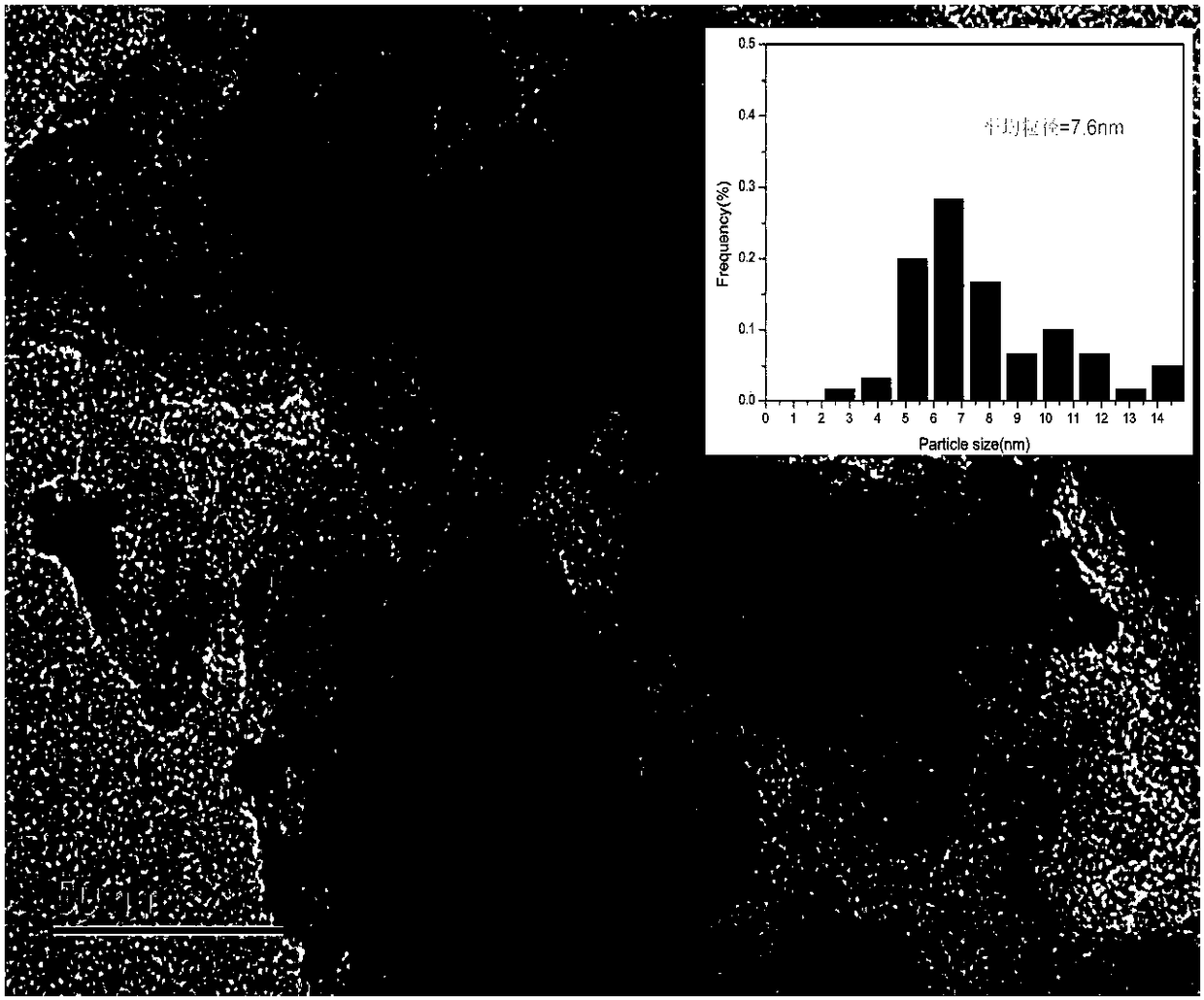

[0022] (1) Carrier preparation: take 1.0g XC-72, 1.3275g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 (0) and 65ml of deionized water in a 250mL three-necked flask; stir and ultrasonic each for 30min; then add 2M KOH aqueous solution dropwise to adjust the pH to 12, continue ultrasonically stirring for 120min, centrifuge and wash until the supernatant is neutral, and vacuum-dry at 60°C 24 hours, then roasted in the air atmosphere for 120min, and cooled naturally in nitrogen to obtain a composite carrier with a diameter of about 7.6nm;

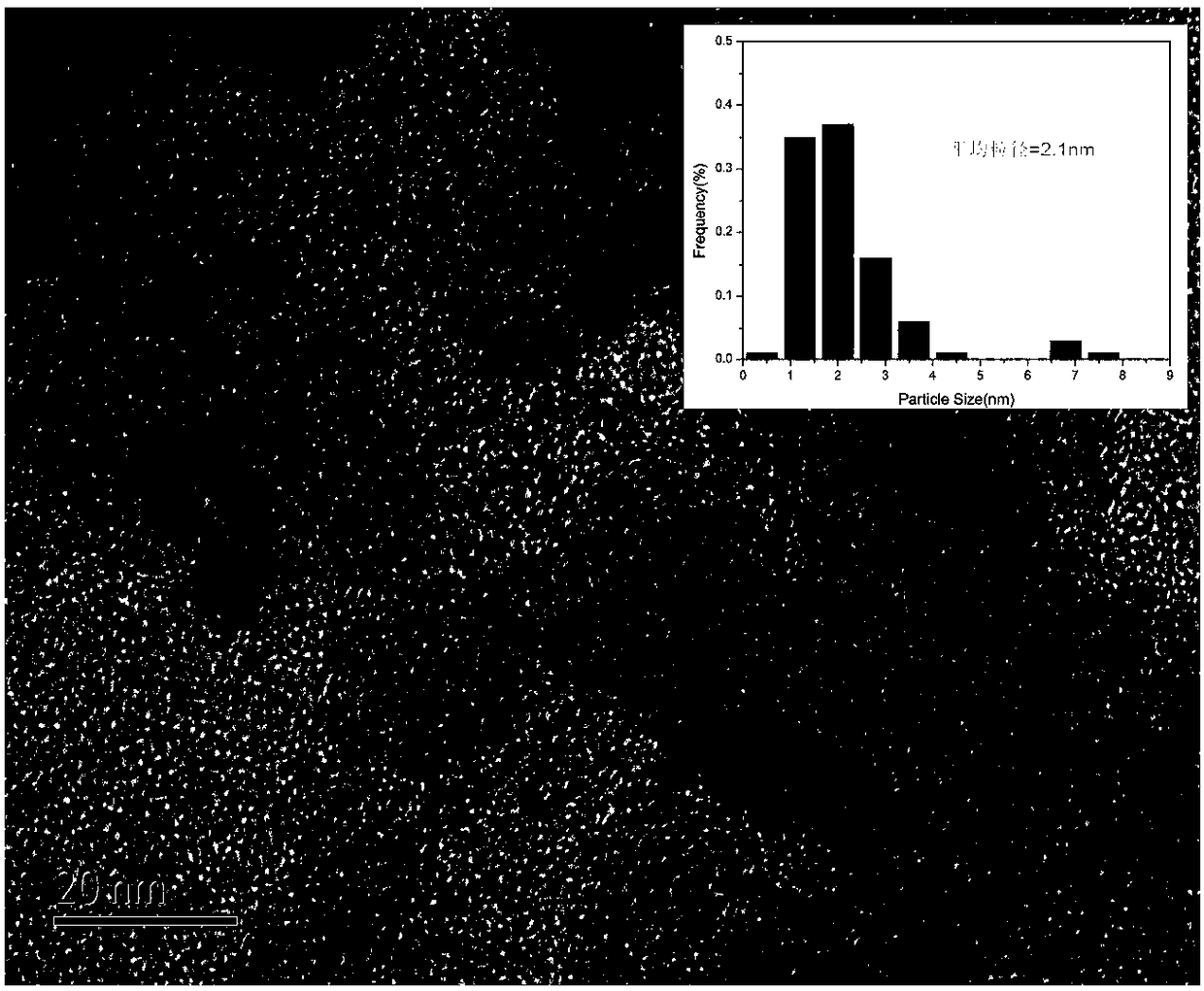

[0023] (2) Catalyst preparation: Take 90 mg of the composite carrier prepared in (1) in a single-necked flask, then add 0.052 mMH 2 IrCl 6 Water solution and 30ml EG solution were ultrasonically stirred for 30 minutes each, the mixed solution was adjusted to pH 12 with NaOH, and refluxed for 3 hours in an oil bath at 120°C, the pH of the reaction solution was adjusted to 3 with HCl, cooled to room temperature, and centrifuged and...

Embodiment 2

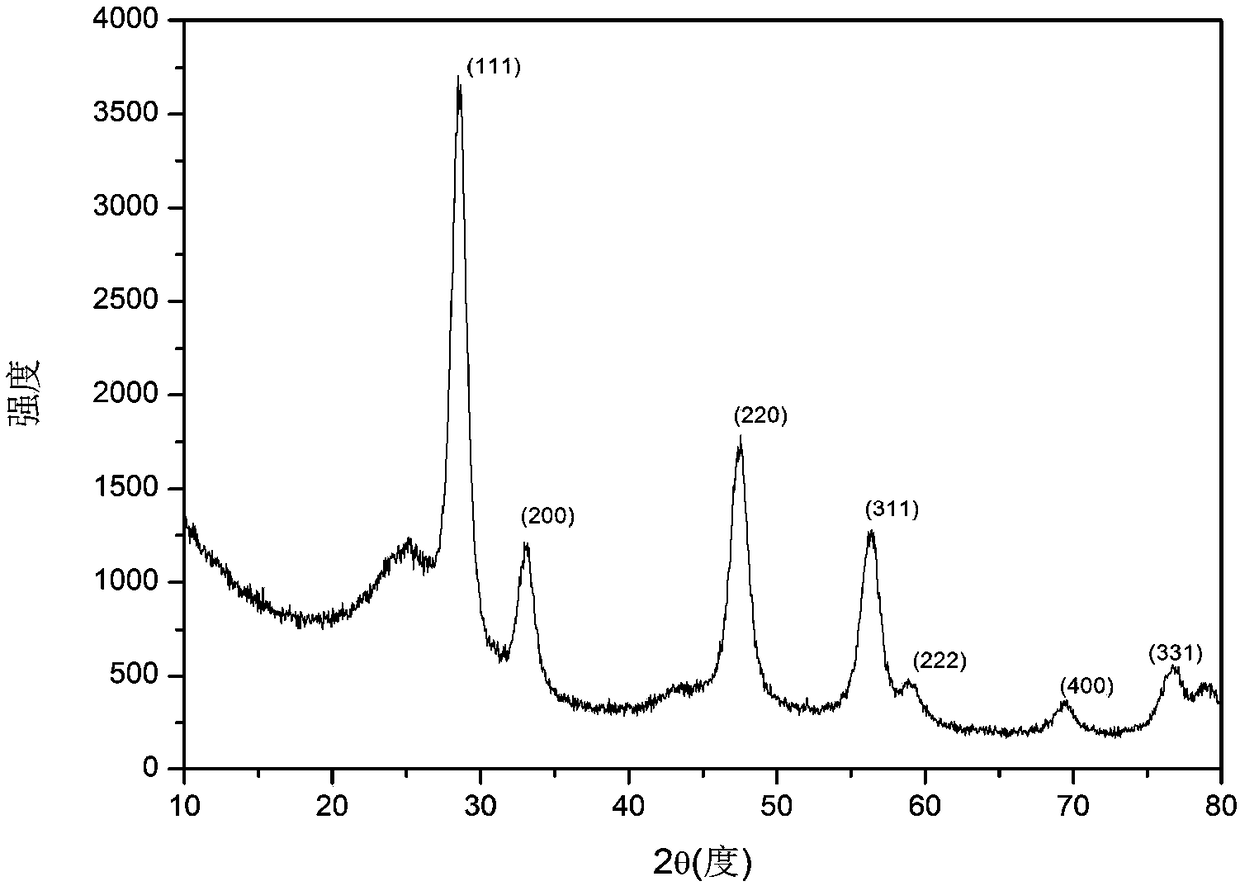

[0025] Get the prepared composite carrier of step (1) in the appropriate example 1 and carry out powder XRD test, the result is as follows figure 1 shown.

Embodiment 3

[0027] Get the prepared composite carrier of step (1) in the appropriate example 1 and carry out TEM test and carry out particle size statistics, the result is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Active area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com