Snake oil composition and preparation method and application thereof

A composition and technology of snake oil, applied in the directions of drug combination, fat oil/fat refining, pharmaceutical formulation, etc., can solve the problems of inability to increase the snake oil content of snake oil products, poor stability of snake oil, failure to exert effectively, etc., and achieve fishy smell. Low odor, high stability, convenient storage and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

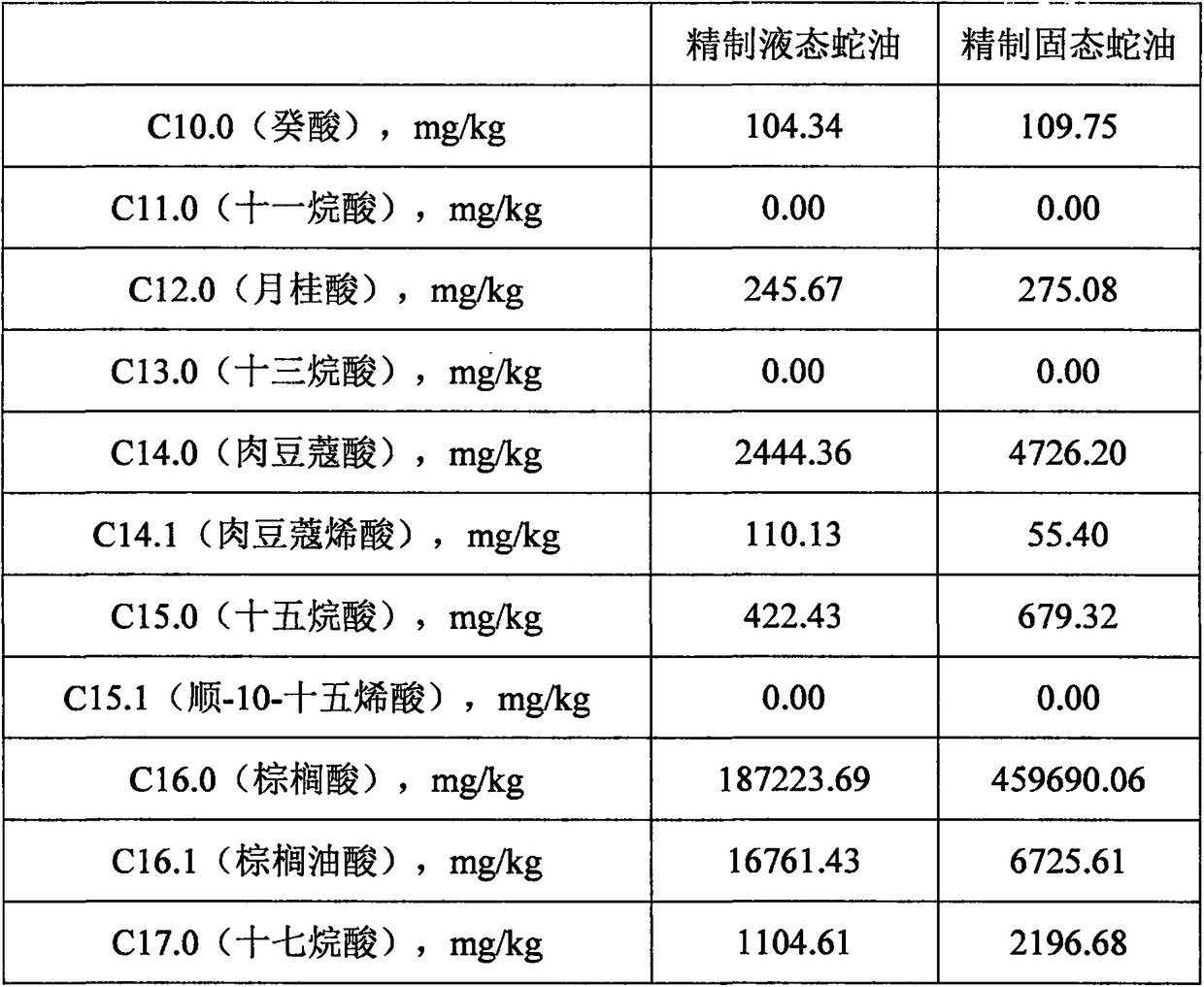

Embodiment 1

[0049] The present embodiment provides a kind of preparation method of refined snake oil, comprises the steps:

[0050] (1) Get 2kg of fresh snake oil fat grain and soak in 10L containing the pretreatment solution that mass concentration is 0.01% citric acid and mass concentration is 0.7% sodium chloride, temperature is 15 ℃ and stirs 4h, after repeating 3 times Drain and set aside;

[0051] (2) Take by weighing the pretreated snake oil fat grain 1kg in step (1) and mix with 100g activated clay, 6kg n-hexane and 0.5g citric acid, after shearing and stirring at 5000rmp with rotating speed for 3min, under sealed condition, After stirring at 800rmp for 1h, filter with a G4 sand core funnel, and remove n-hexane in the filtrate by vacuum rotary evaporation at 35°C to obtain snake oil;

[0052] (3) Add the snake oil in step (2) into n-hexane for freezing, the mass ratio of snake oil and n-hexane is 1:2, freeze at -5°C for 25h and separate the solid and liquid to obtain the filtrate...

Embodiment 2

[0055] (1) get 2kg of fresh snake oil fat granule and soak in 6L containing the vitamin C that mass concentration is 0.05% and the pretreatment liquid that mass concentration is 2% sodium chloride, temperature is 0 ℃ and stirs 5h, after repeating 6 times Drain and set aside;

[0056] (2) 1kg of pretreated snake oil fat particles in step (1) is mixed with 10g alumina, 3kg ether and 0.1g tea polyphenols, after shearing and stirring at 10000rmp for 0.5min, under sealed conditions, After stirring at 200rmp for 2h, filter with a G4 sand core funnel, and remove ether in the filtrate by vacuum rotary evaporation at 30°C to obtain crude snake oil;

[0057] (3) Add the snake oil in step (2) to diethyl ether for freezing, the mass ratio of snake oil and diethyl ether is 1:1, freeze at -10°C for 20 hours to separate solid-liquid into filtrate and solid, and rotate under vacuum at 30°C Evaporate and remove the ether in the filtrate to obtain the liquid snake oil crude product, mix the so...

Embodiment 3

[0060] (1) Take 2kg of fresh snake oil fat grains and soak them in 12L of pretreatment liquid containing 0.03% tea polyphenols and 0.1% sodium chloride, stir at 25°C for 2 hours, repeat twice Drain and set aside;

[0061] (2) Mix 1 kg of pretreated snake oil fat particles in step (1) with 300 g of silica gel, 10 kg of ethanol and 1 g of vitamin C, and after shearing and stirring at a speed of 200 rpm for 10 min, stir at a speed of 1000 rpm for 0.5 h under sealed conditions Finally, filter with No. G4 sand core funnel (aperture is 3-4 μm), vacuum rotary evaporation removes the ethanol in the filtrate under 40 ℃, obtains snake oil crude product;

[0062] (3) Add the snake oil in step (2) to ethanol for freezing, the mass ratio of snake oil and ethanol is 1:3, freeze at 0°C for 30 hours to separate the solid and liquid to obtain filtrate and solids, and vacuum rotary evaporation at 40°C Remove the ethanol in the filtrate to obtain the liquid snake oil crude product, mix the soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com