A kind of preparation method of Mn-ce-ti-o composite metal oxide catalyst

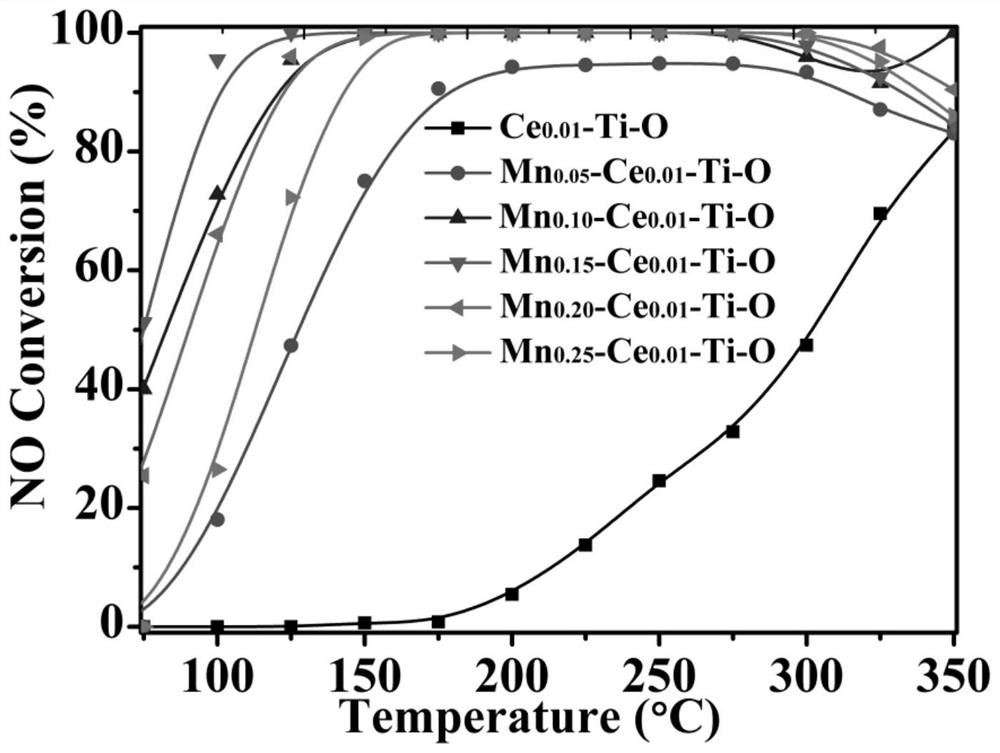

A mn-ce-ti-o, composite metal technology, applied in the field of metal oxide catalyst preparation, can solve the problems of insufficient NOx elimination ability, unsatisfactory catalyst activity, unstable catalyst activity, etc., and achieve high NOx elimination ability , good dispersibility, simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of Mn-Ce-Ti-O composite metal oxide catalyst, concrete operation steps are as follows:

[0030] (1) Measure tetrabutyl titanate and absolute ethanol according to the volume ratio of 1:1, put 20ml of tetrabutyl titanate into a beaker and stir on a multi-point magnetic stirrer. Add absolute ethanol dropwise to tetrabutyl titanate at a rate of 0.5ml / min, add 20ml of absolute ethanol dropwise, and stir and mix for 40min;

[0031] (2) Manganese nitrate (H 8 MnN 2 o 10 ) and cerium nitrate (Ce(NO 3 ) 2 ·6H 2 O) be dissolved in 20ml dehydrated alcohol, dissolve completely to cerium nitrate, stir and mix, obtain the mixed solution of manganese nitrate and cerium nitrate;

[0032](3) Slowly add the mixed solution of manganese nitrate and cerium nitrate obtained in step (2) dropwise to the substance obtained in step (1), stir evenly, then add 18.9126g citric acid monohydrate into it and stir to dissolve and let it stand for one time Aging, agin...

Embodiment 2

[0036] A kind of preparation method of Mn-Ce-Ti-O composite metal oxide catalyst, concrete operation steps are as follows:

[0037] (1) Measure tetrabutyl titanate and absolute ethanol according to the volume ratio of 1:1, put 20ml of tetrabutyl titanate into a beaker and stir on a multi-point magnetic stirrer. Add absolute ethanol dropwise to tetrabutyl titanate at a rate of 1ml / min, add 20ml of absolute ethanol dropwise, and stir and mix for 40min;

[0038] (2) Manganese nitrate (H 8 MnN 2 o 10 ) and cerium nitrate (Ce(NO 3 ) 2 ·6H 2 O) be dissolved in 20ml dehydrated alcohol, dissolve completely to cerium nitrate, stir and mix, obtain the mixed solution of manganese nitrate and cerium nitrate;

[0039] (3) Slowly add the mixed solution of manganese nitrate and cerium nitrate obtained in step (2) dropwise to the substance obtained in step (1), stir evenly, then add 18.9126g citric acid monohydrate into it and stir to dissolve and let it stand for one time Aging, aging...

Embodiment 3

[0043] A kind of preparation method of Mn-Ce-Ti-O composite metal oxide catalyst, concrete operation steps are as follows:

[0044] (1) Measure tetrabutyl titanate and absolute ethanol according to the volume ratio of 1:1, put 20ml of tetrabutyl titanate into a beaker and stir on a multi-point magnetic stirrer. Add absolute ethanol dropwise to tetrabutyl titanate at a rate of 2ml / min, add 20ml of absolute ethanol dropwise, and stir and mix for 40min;

[0045] (2) Manganese nitrate (H 8 MnN 2 o 10 ) and cerium nitrate (Ce(NO 3 ) 2 ·6H 2 O) be dissolved in 20ml dehydrated alcohol, dissolve completely to cerium nitrate, stir and mix, obtain the mixed solution of manganese nitrate and cerium nitrate;

[0046] (3) Slowly add the mixed solution of manganese nitrate and cerium nitrate obtained in step (2) dropwise to the substance obtained in step (1), stir evenly, then add 18.9126g citric acid monohydrate into it and stir to dissolve and let it stand for one time Aging, aging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com