Low metamorphic coal-zirconium-based catalyst as well as preparation method and application thereof

A low metamorphic coal and catalyst technology, applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of high energy consumption, low utilization rate, inability to effectively utilize oxygen-containing functional groups and low-molecular organic matter and other issues to achieve the effect of good selectivity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a low-alteration coal-zirconium-based catalyst, comprising the following steps:

[0024] mixing the base material with a sodium hydroxide solution for pretreatment to obtain a base material dispersion, the base material being low metamorphic coal or low metamorphic coal derivatives;

[0025] The pH value of the base material dispersion is adjusted to 2-6, and then mixed with the soluble zirconium salt for coordination and complexation reaction to obtain a low-modification coal-zirconium-based catalyst.

[0026] In the invention, the base material is mixed with the sodium hydroxide solution for pretreatment to obtain the base material dispersion liquid. In the present invention, the base material is low-metamorphic coal or low-metamorphic coal derivatives, and the low-metamorphic coal preferably includes one of lignite raw coal, bituminous coal, sub-bituminous coal, long-flame coal, coking coal and lean coal, more preferably ...

Embodiment 1

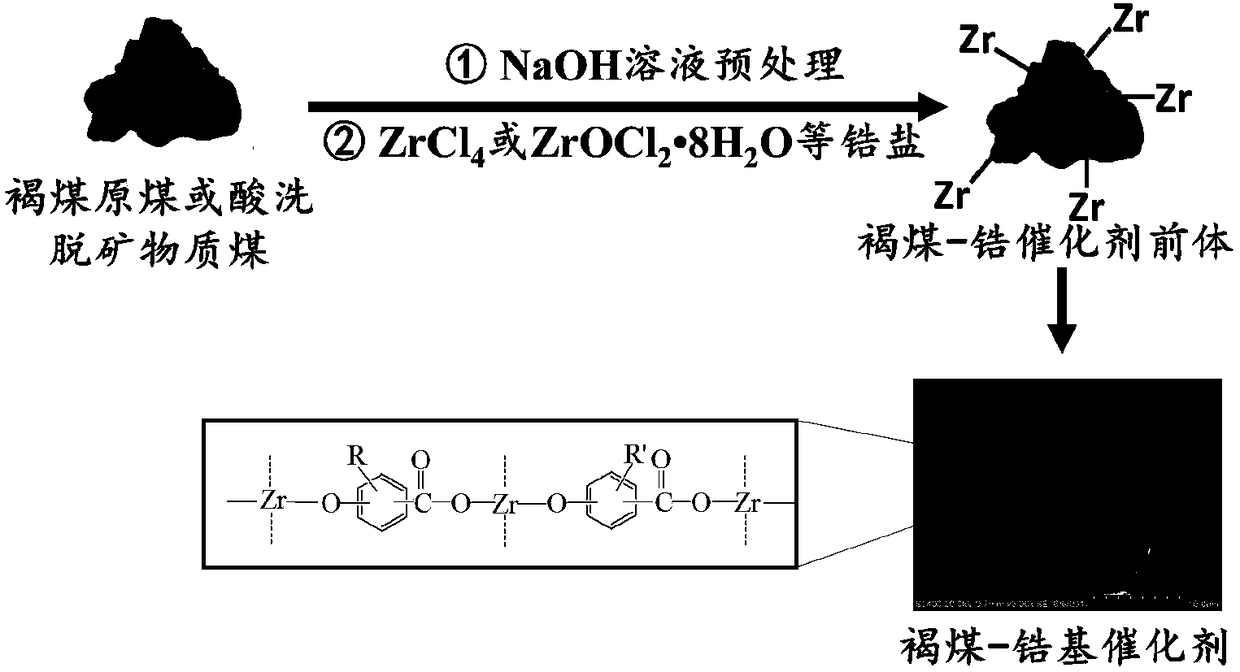

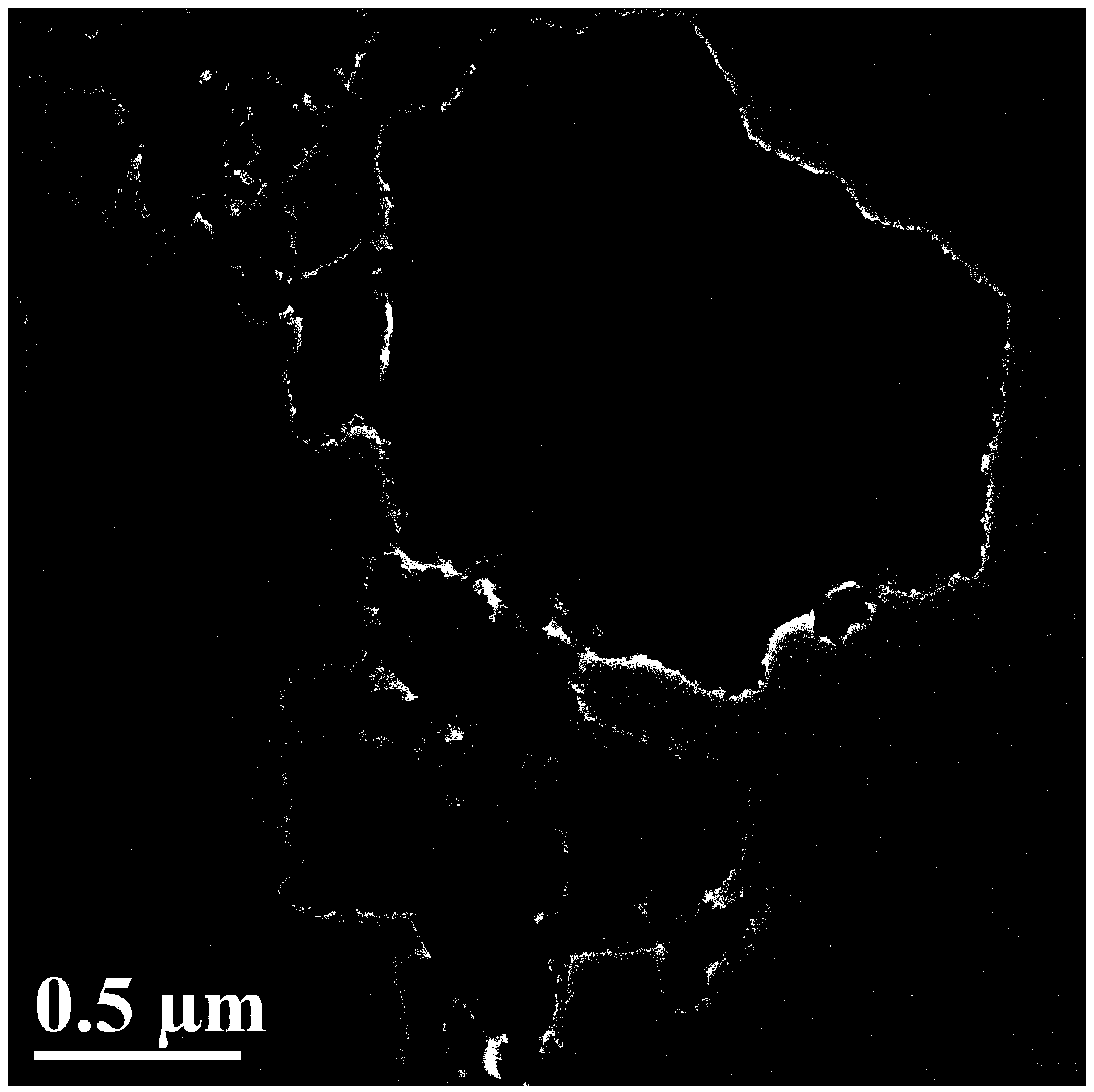

[0052] Such as figure 1 As shown, after lignite raw coal or acid-eluted mineral coal is pretreated with NaOH solution, the acidic oxygen-containing functional groups such as carboxyl-COOH and phenolic hydroxyl-OH are transformed into ionic forms-COO - ,-O - , these functional groups are associated with Zr 4+ Coordination complexation occurs, each Zr 4+ Can be complexed with at least four functional groups to form Zr 4+ Centered spatial network structure.

[0053] Specific steps are as follows:

[0054] (1) Lignite raw material preparation: dry lignite raw coal at 100° C. for 24 hours, then pulverize, grind, and sieve to obtain lignite powder with an average particle size of 100-400 mesh.

[0055] (2) The above lignite powder was treated with NaOH solution with a concentration of 0.1 mol / L at 25° C. for 2 h to pH 3-7, and then used for the next reaction.

[0056] (3) coal zirconium reaction: according to ZrCl 4 The mass ratio of the lignite raw material is 0.5:1. Weigh t...

Embodiment 2

[0076] (1) Bituminous coal raw material preparation: dry bituminous coal raw coal at 110°C for 10 hours, then pulverize, grind, and sieve to obtain bituminous coal powder with an average particle size of 150-350 mesh; Remove the inherent minerals in the coal, and then wash it repeatedly with a large amount of deionized water to remove excess Cl - , and then proceed to the next step of NaOH treatment.

[0077] (2) The above acid-washed coal samples were treated with 0.5mol / L NaOH solution at 25°C for 5h to pH 3-7, and then used for the next reaction.

[0078] (3) coal zirconium reaction: according to ZrOCl 2 ·8H 2 The mass ratio of O to bituminous coal raw material is 7:1. Weigh the zirconium salt and dissolve it in 100mL deionized water. Slowly add the suspension of the above bituminous coal raw material into the zirconium salt solution, and stir and react at 60°C for 2h.

[0079] (3) Filtration and washing: After the reaction is over, filter the suspension obtained from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com