Chip embedded compound for electron beam exposure and preparation method and application thereof

A technology of electron beam exposure and composites, which is applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of waste of lithography area, small chips cannot be directly spun glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The first aspect of the embodiment of the present application provides a method for preparing a chip embedded composite for electron beam exposure, including the following steps:

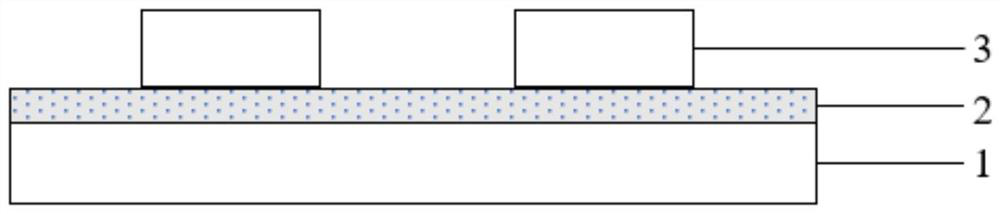

[0032] S01. A composite structure is provided, wherein the composite structure includes a first substrate, a conductive layer disposed on a surface of the first substrate, and a chip array disposed on a surface of the conductive layer away from the first substrate;

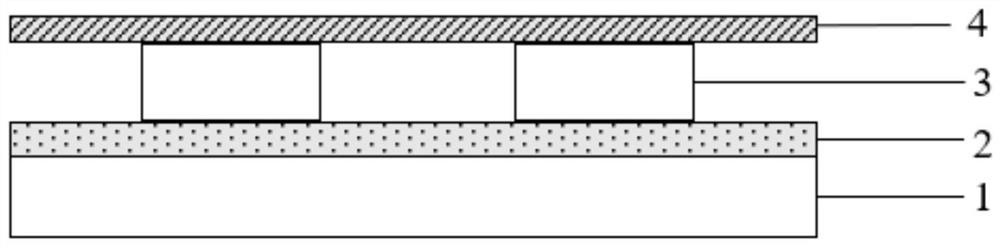

[0033] S02. laying a protective layer on the outer surface of the chip array, and the protective layer covers the chip array;

[0034] S03. Encapsulating and curing the composite structure and the protective layer by using a polymer solution;

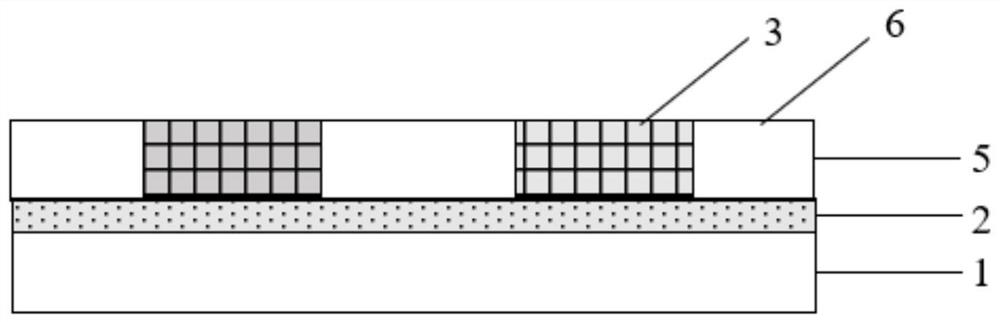

[0035] S04. Removing the protective layer to obtain a chip embedding compound.

[0036]The first aspect of the present application provides a method for preparing a chip embedded composite for electron beam exposure. The preparation method uses a composite structure including a chip as a ...

Embodiment 1

[0101] Chip-embedded compound for electron beam exposure and its preparation method

[0102] Preparation method of chip embedded compound

[0103] This preparation method comprises the steps:

[0104] Provide two unspun photoelectric semiconductor small chips (2mm*4mm), two (100) crystal orientation P or N-doped silicon wafers (8mm*10mm), a glass dish with a diameter of 60mm, 10ml PDMS solution A, 1ml PDMS liquid B (curing agent), ECA-1003 conductive adhesive, PMMA electronic adhesive. Required instruments: constant temperature hot plate, glue spinner, nitrogen gun, vacuum machine, step meter;

[0105] Such as Figure 5 As shown, a composite structure is provided, wherein the composite structure includes a first substrate, a conductive layer disposed on the surface of the first substrate, and a chip array disposed on the surface of the conductive layer away from the first substrate; Protective layer, the protective layer covers the chip array:

[0106] Use acetone and i...

Embodiment 2

[0116] Chip-embedded compound for electron beam exposure and its preparation method

[0117] Preparation method of chip embedded compound

[0118] This preparation method comprises the steps:

[0119] Provide two unspun photoelectric semiconductor small chips (2mm*4mm), two (100) crystal orientation P or N-doped silicon wafers (8mm*10mm), a glass dish with a diameter of 60mm, 10ml PDMS solution A, 1ml PDMS liquid B (curing agent), ECA-1003 conductive adhesive, PMMA electronic adhesive. Required instruments: constant temperature hot plate, glue spinner, nitrogen gun, vacuum machine, step meter;

[0120] A composite structure is provided, wherein the composite structure includes a first substrate, a conductive layer disposed on the surface of the first substrate, and a chip array disposed on a surface of the conductive layer away from the first substrate; a protective layer is laid on the outer surface of the chip array, A protective layer covers the array of chips:

[012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com